Product Overview

The Pure Nickel Extreme High Temperature Cable redefines thermal resilience in critical environments. Engineered with 99.9% pure nickel conductors and multi-layer ceramic insulation, this cable delivers unmatched performance at continuous 1000°C and peak 1500°C. Ideal for aerospace, metallurgy, and energy applications where conventional cables fail.

Key Features & Benefits

| Property | Specification |

|---|---|

| Rated Voltage | 300/500V AC/DC |

| Temp Range | Continuous: 1000°C • Peak: 1500°C |

| Conductor | Twisted Pure Nickel Wire (Alkali Resistant) |

| Insulation System | Fiberglass Braid + Mica Tape + High-Temp Yarn |

| Key Advantages | Zero Melt Risk • Chemical Immunity • Non-Combustible |

| Color Options | 12+ Colors (Red/Yellow/Blue/Black/Custom) |

Technical Specifications

Complete Electrical & Mechanical Properties

| Section (mm²) | Conductor Construction | Wire OD (mm) | Packaging (m/roll) | Max Current (500V/A) |

|---|---|---|---|---|

| 0.50 | 7×0.30 | 2.6 | 200 | 9.2 |

| 0.75 | 11×0.30 | 2.7 | 200 | 13.8 |

| 1.00 | 14×0.30 | 2.8 | 200 | 18.4 |

| 1.50 | 21×0.30 | 3.0 | 100 | 27.6 |

| 2.50 | 35×0.30 | 3.6 | 100 | 46.0 |

| 4.00 | 56×0.30 | 4.5 | 100 | 73.6 |

| 6.00 | 84×0.30 | 5.5 | 100 | 110.4 |

| 10.00 | 140×0.30 | 6.6 | 100 | 184.0 |

| 16.00 | 228×0.30 | 7.8 | 100 | 294.4 |

| 25.00 | 361×0.30 | 9.5 | 100 | 460.0 |

| 35.00 | 494×0.30 | 11.2 | 100 | 644.0 |

| 50.00 | 703×0.30 | 13.2 | 100 | 920.0 |

| 70.00 | 988×0.30 | 15.4 | 100 | 1288.0 |

| 95.00 | 760×0.30* | 17.4 | 100 | 1748.0 |

*Note: 95mm² uses optimized compaction • Current ratings @ 500V continuous duty • Tolerance: OD ±0.2mm

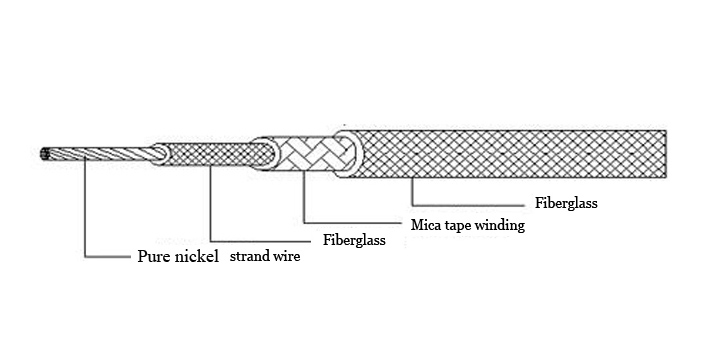

Construction & Materials

-

Conductor:

-

99.9% Pure Nickel Strands (ASTM B160)

-

Alkali resistance 2× superior to stainless steel

-

-

Insulation System (Triple-Layer):

-

Layer 1: High-Temp Ceramic Yarn (>1800°C rating)

-

Layer 2: Fire-Resistant Fluorophlogopite Mica Tape

-

Layer 3: Fiberglass Braid (EN ISO 2078 certified)

-

-

Critical Properties:

-

Thermal shock resistance: 100+ cycles (1000°C↔25°C)

-

Zero halogen emission • Acid/alkali resistance (pH 0-14)

-

Application Scenarios

-

Metallurgy: Electric arc furnaces, ladle preheating, molten metal handling

-

Energy: Nuclear reactor instrumentation, plasma generator links

-

Aerospace: Rocket engine test stands, re-entry vehicle sensors

-

Industrial: Cement kilns, glass manufacturing, ceramic sintering

-

Military: Jet engine harnesses, armor systems, missile guidance

Engineering Selection Guide

| Requirement | Configuration Tip |

|---|---|

| Temp Exposure | Continuous >800°C: Mandatory use |

| Current Capacity | Derate 0.5%/°C above 1000°C |

| Chemical Exposure | Essential for caustic/alkaline environments |

| Vibration Resistance | Nickel's fatigue strength 3× copper alloys |

| Customization | Armored variants • Custom lengths • EM shielding |

Performance Advantages

-

Thermal Integrity: No degradation at 1000°C/1000hrs (ASTM E119)

-

Safety: Non-combustible (ISO 834 Class A1) • Zero toxic fumes

-

Longevity: 10-year service life in 800°C+ environments

-

Conductivity: 25% better than chromel alloys at 1000°C

Standards & Certifications

-

Materials: ASTM B160 • EN ISO 2078 • IEC 60371-3

-

Safety: MIL-W-87181 • BS 6387 CWZ Grade

-

Testing: 100% HIPOT @ 3kV • Thermal cycling per IEC 60068-2-14