Product Overview

The Industrial Silicone Data Cable Series delivers unmatched reliability in extreme environments. Engineered with fluoroplastic insulation and silicone rubber sheathing, these cables maintain signal integrity under continuous thermal stress (-60°C to +180°C) while resisting corrosion, aging, and EMI. Ideal for critical data transmission in industrial automation, energy, and harsh process environments.

Key Features & Benefits

| Property | Specification |

|---|---|

| Rated Voltage | 300/500V AC |

| Temperature Range | -60°C to +180°C Continuous Operation |

| Shielding Options | Individual Pair + Overall Braid/Tape Shields |

| Flame Retardancy | GB/T 18380.3-2001 Class A Certified |

| Key Advantages | Chemical Resistance • EMI Immunity • Extreme Flexibility |

| Bending Radius | 6× OD (Standard) • 12× OD (Shielded/Armored) |

Technical Specifications

Electrical & Mechanical Properties

| Section (mm²) | Max Conductor Resistance (Ω/km) | Insulation Resistance (MΩ·km) | Test Voltage | |

|---|---|---|---|---|

| Class A/B | Class R | ≥30 @ 20°C | AC 1500V/5min | |

| 0.50 | 36.0 | 39.0 | ||

| 0.75 | 24.5 | 26.0 | ||

| 1.00 | 18.1 | 19.5 | ||

| 1.50 | 12.1 | 13.3 | ||

| 2.50 | 7.41 | 7.98 |

Note: Class A/B = Solid Conductor • Class R = Stranded Conductor

Product Models & Configurations

| Model | Construction | Shielding Type | Application |

|---|---|---|---|

| DJFGP | Fluoroplastic Insulation + Silicone Sheath | Overall Copper Braid | General EMI Protection |

| DJFPGP | Fluoroplastic Insulation + Silicone Sheath | Individual + Overall Copper Braid | Critical Signal Integrity |

| DJFPG | Fluoroplastic Insulation + Silicone Sheath | Individual Pair Braid | Partial EMI Shielding |

| DJFGP2 | Fluoroplastic Insulation + Silicone Sheath | Overall Copper Tape | High-Frequency Noise Rejection |

| DJFP2GP2 | Fluoroplastic Insulation + Silicone Sheath | Individual + Overall Copper Tape | Military/Grade Precision Systems |

| Soft Variants | |||

| DJFGPR | Flexible Fluoroplastic + Silicone | Overall Braid (Flexible) | Robotic Arms • Moving Machinery |

| DJFPGPR | Flexible Fluoroplastic + Silicone | Individual + Overall Braid (Flexible) | CNC Systems • Dynamic Sensor Networks |

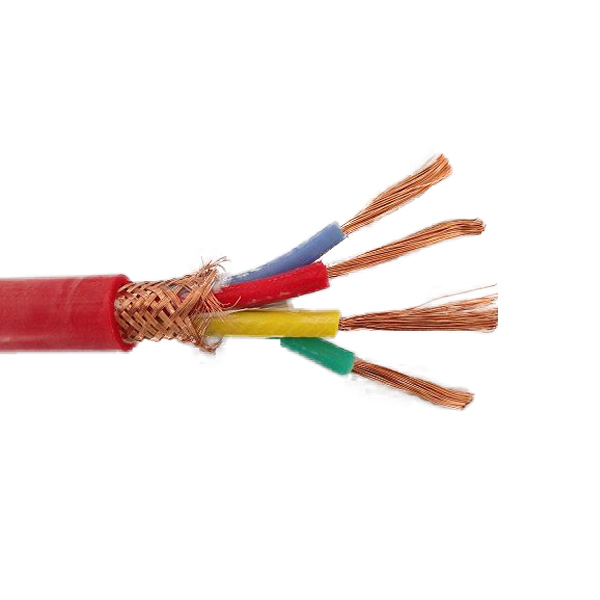

Construction & Materials

-

Conductor:

-

Oxygen-free copper (Class A/B solid or Class R stranded)

-

-

Insulation:

-

Fluoroplastic (PTFE/FEP) providing:

-

Dielectric constant: ≤2.1 • Signal loss <0.1dB/m

-

Chemical inertness (pH 0-14 resistance)

-

-

-

Shielding:

-

Dual-layer: Copper braid (95% coverage) + Aluminum-mylar tape

-

-

Sheath:

-

Reinforced silicone rubber with:

-

50% tear strength improvement vs. standard silicone

-

UV/Ozone resistance per IEC 60811

-

-

Application Scenarios

-

Industrial Automation: PLC systems, motor control centers, DCS networks

-

Energy: Wind turbine pitch control, solar farm monitoring, substation SCADA

-

Process Industries: Petrochemical refineries, pharmaceutical batch reactors

-

Transportation: Railway signaling, aircraft test benches, ship engine rooms

-

Harsh Environments: Foundries, cryogenic facilities, offshore platforms

Engineering Selection Guide

| Requirement | Recommended Model | Critical Parameters |

|---|---|---|

| EMI Susceptibility | DJFP2GP2 (Dual Tape Shield) | 100dB EMI attenuation @ 1GHz |

| Flexibility | DJFPGPR (Flexible Shielded) | Withstands 1M+ bend cycles |

| Chemical Exposure | All Models | Resists acids/alkalis/solvents |

| High Moisture | DJFGP2 (Tape Shield) | 100% moisture barrier |

| Cost Optimization | DJFPG (Individual Shield) | Balanced performance for moderate EMI |

Performance Advantages

-

Signal Integrity: <0.05% crosstalk in 1m bundled runs

-

Thermal Endurance: No brittleness after 500hrs @ 180°C

-

Safety Compliance: Halogen-free • Low smoke density (IEC 61034)

-

Lifespan: 15+ years in chemical environments

Standards & Certifications

-

Electrical Testing: IEC 60332-1 (Flame) • IEC 61156 (Data Transmission)

-

Material Compliance: RoHS • REACH • UL 94 V-0