Product Overview

Engineered for extreme industrial environments, this triple-layer silicone-fiberglass cable delivers 180°C continuous heat resistance with unmatched flexibility. Featuring tinned copper conductors, silicone insulation, and protective fiberglass braiding, it withstands demanding applications in power generation, metallurgy, and heavy machinery where standard cables fail.

Key Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 600V/1000V AC |

| Temp Range | -60°C to +180°C Continuous |

| Conductor Options | Tinned or Plain Copper (Class 5) |

| Insulation | Silicone Rubber |

| Braiding | Fiberglass |

| Multi-Core Options | 2,3,4,5,3+1,3+2,4+1 Cores |

![]()

Construction & Technical Data

Standard Sizes (DC Resistance at 20°C)

| Size (mm²) | Tinned Copper (Ω/km) | Plain Copper (Ω/km) |

|---|---|---|

| 4 | 5.09 | 4.95 |

| 6 | 3.39 | 3.30 |

| 10 | 1.95 | 1.91 |

| 16 | 1.24 | 1.21 |

| 25 | 0.795 | 0.78 |

| 35 | 0.565 | 0.554 |

| 50 | 0.393 | 0.386 |

| 70 | 0.277 | 0.272 |

| 95 | 0.21 | 0.206 |

Small Conductor Specifications

| AWG | Conductor Structure | Ø Cond. (mm) | Insul. Thick. (mm) | Braid Thick. (mm) | Ø Cable (mm) |

|---|---|---|---|---|---|

| 18 | 7/0.395 | 1.2 | 0.78 | 0.15 | 3.2-3.5 |

| 16 | 7/0.495 | 1.5 | 0.78 | 0.15 | 3.6-3.9 |

| 14 | 41/0.25 | 1.82 | 0.78 | 0.20 | 4.0-4.5 |

| 12 | 45/0.32 | 2.5 | 0.78 | 0.20 | 5.2-5.7 |

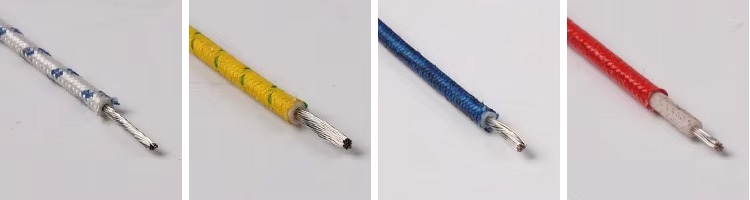

Multi-Layer Construction

-

Conductor:

-

Class 5 stranded copper (tinned or plain)

-

Optimized stranding for maximum flexibility

-

Oxidation-resistant tinned option available

-

-

Insulation:

-

High-temperature silicone rubber

-

Maintains elasticity at 180°C

-

UL94 V-0 flame retardant rating

-

-

Braiding:

-

Woven fiberglass outer layer

-

Provides mechanical protection

-

Additional thermal barrier

-

(Optional: Copper braid screening/steel tape armor/PVC sheath)

Performance Advantages

-

Extreme Heat Resistance

Continuous operation at 180°C (356°F) - 3x higher than PVC cables -

Superior Flexibility

10-12x bending radius (unarmored/armored) for tight installations -

Chemical Resilience

Resists oils, acids, and industrial solvents -

Abrasion Protection

Fiberglass braid withstands mechanical stress -

Multi-Core Options

Control/power combinations (3+1, 4+1 cores) available

Industrial Applications

-

Power Generation: Turbine wiring, generator connections

-

Heavy Industry: Furnace controls, kiln wiring, metal processing

-

Material Handling: Port crane systems, conveyor heating

-

Chemical Plants: Reactor instrumentation, pump wiring

-

HVAC Systems: Industrial heater connections

-

Automotive Manufacturing: Paint booth equipment, curing ovens

Engineering Benefits

-

Vibration Resistance

Stranded construction withstands equipment vibration -

Easy Termination

Compatible with standard lugs and connectors -

Long Service Life

15,000 hours at 180°C operating temperature

-

Safety Compliance

Meets IEC 60332-1 flame propagation standards

Configuration Options

| Component | Standard | Custom Options |

|---|---|---|

| Conductor | Tinned copper | Plain copper |

| Core Configuration | Single-core | 2-5 cores, 3+1, 4+1 |

| Shielding | - | Copper braid screen |

| Armoring | - | Steel tape |

| Outer Sheath | Fiberglass braid | Silicone/PVC |

| Colors | Black, Red, Yellow | 10+ color options |

Selection Guidelines

| Application | Recommended Size | Core Configuration |

|---|---|---|

| Industrial Oven Elements | 4-10mm² | Single-core |

| Motor Power Connections | 16-35mm² | 3-core or 4-core |

| Crane Control Systems | 4-6mm² | 5-core |

| High-Current Feeds | 50-95mm² | Single-core |

| Instrumentation Circuits | 18-12 AWG | 3+1 core |

Custom voltage ratings (up to 30kV) and temperature grades available