Product Overview

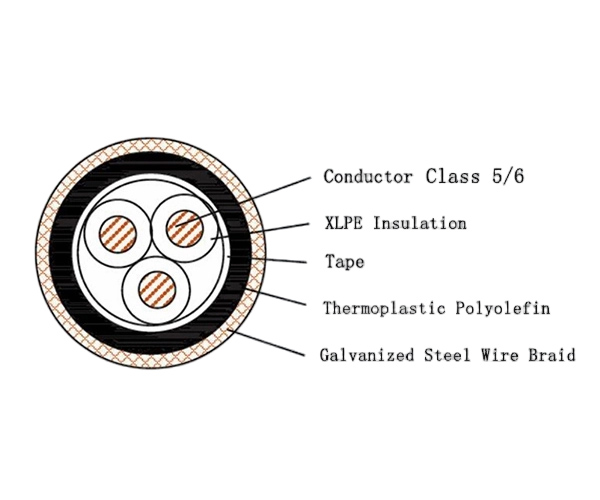

The CJPFR90/SC is a halogen-free, low-smoke, flame-retardant marine flexible power cable designed for applications demanding both high flexibility and superior mechanical protection. Its construction combines fine-strand Class 5/6 conductors for easy installation with a galvanized steel wire braid armor for crush and impact resistance, making it a robust solution for dynamic or exposed circuit paths on ships and offshore installations.

Technical Specifications

-

Rated Voltage (U₀/U): 0.6/1 kV

-

Maximum Continuous Conductor Temperature: 90°C

-

Conductor: Class 5/6 (Fine Strand) Tinned Annealed Copper Wire (IEC 60228)

-

Available Cross-Sections: 0.75 mm² to 300 mm²

-

Core Configurations: 1 to 37 Cores

Cable Construction & Materials

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Class 5/6(R) Tinned Annealed Copper Wire |

| Insulation | J | XLPE Insulated |

| Inner Sheath | PF | Thermoplastic Polyolefin(SHF1) |

| Armor | 9 | Galvanized Steel Wire Braid |

| Outer Sheath | 0 | Without Outer Sheath |

| Flammability | SC | Halogen Free Low Smoke Flame Retardant |

Key Performance Characteristics

-

Flexible & Robust: The fine-stranded (Class 5/6) tinned copper conductor ensures excellent flexibility for routing in confined spaces, while the galvanized steel wire armor provides high tensile strength and robust protection against mechanical damage.

-

Flame Retardant: Complies with IEC 60332-1 and IEC 60332-3-22, effectively inhibiting the propagation of flame along the cable.

-

Halogen Free & Low Smoke: The inner sheath material (SHF1) is halogen-free (IEC 60754) and generates low smoke density (IEC 61034) in case of fire, enhancing safety by reducing corrosive gas emission and improving visibility.

-

High-Strength Armor: The galvanized steel wire braid offers superior resistance to crushing, impact, and rodent bites compared to non-armored or lightly armored alternatives, suitable for exposed or hazardous routing areas.

-

Thermal Endurance: XLPE insulation provides stable electrical performance and maintains flexibility at a continuous operating temperature of up to 90°C.

Standards & Compliance

This cable is designed and tested in accordance with the following international standards:

-

IEC 60092-350, 353 (General construction and armor requirements)

-

IEC 60228 (Conductors)

-

IEC 60092-360 (Insulation and sheath materials)

-

IEC 60332-1 & IEC 60332-3-22 (Tests for flame retardancy)

Typical Applications

This armored flexible cable is ideal for applications requiring both movement/ ease of installation and mechanical protection:

-

Marine & Offshore: Flexible power and control connections in engine rooms, for moving equipment, in control systems, and on offshore platforms where cables may be subject to physical stress or need to be routed through tight spaces.

-

Industrial: Wiring in harsh industrial environments such as mining, metallurgy, and heavy machinery, where resistance to impact, crushing, and abrasion is critical alongside installation flexibility.