Product Overview

The CJPJP80/NC is a premium fire resistant marine cable designed for critical circuits where enhanced thermal and mechanical performance of the sheath is required alongside guaranteed circuit integrity during fire. It combines the essential fire-survival technology of Mica Glass Tape + XLPE composite insulation with the superior durability of a Cross-linked Polyolefin (SHF2) inner sheath. Protected by a flexible, corrosion-resistant tinned copper braid armor and a collective screen, this cable ensures continuous power to vital systems in a fire while offering excellent resistance to heat deformation, cracking, and harsh environments for demanding marine and industrial safety applications.

Key Features & Benefits

-

Certified Fire Resistance (IEC 60331): Guarantees continued operation of emergency and essential circuits under direct flame and mechanical shock, critical for life safety systems like emergency lighting, alarms, and fire pumps.

-

Enhanced Thermal Sheath Performance: Features a Cross-linked Polyolefin (SHF2) inner sheath, which provides superior resistance to high temperatures, deformation, and mechanical stress compared to standard thermoplastics, ensuring long-term sheath integrity in demanding conditions.

-

Fire-Survival Core Construction: The Mica Glass Tape layer over XLPE insulation creates a robust ceramic barrier under intense heat, maintaining electrical insulation properties and preventing circuit failure during a fire event.

-

Superior Fire Safety (LSZH): Complies with IEC 60754 (Halogen Free) and IEC 61034 (Low Smoke), minimizing the emission of corrosive/toxic gases and smoke density to facilitate safer evacuation and protect equipment.

-

Flexible & Corrosion-Resistant Armor: A braid of tinned copper wires offers excellent flexibility for installation, ease of termination, and reliable corrosion resistance in humid and saline marine atmospheres.

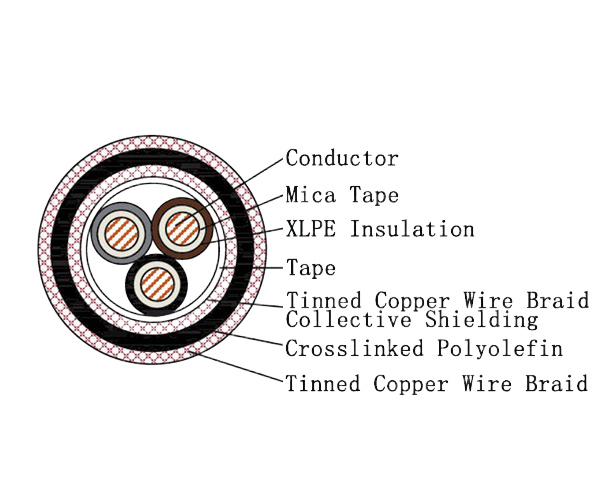

Cable Construction

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned or Plain Stranded Annealed Copper Wire (IEC 60228) |

| Insulation | J | Mica Glass Tape + XLPE Insulated |

| Inner Sheath | PJ | Cross-linked Polyolefin (SHF2) - Halogen Free, Low Smoke |

| Screen | P | Collective Copper Screen |

| Armour | 8 | Braid of Tinned or Plain Copper Wires |

| Outer Sheath | 0 | Without Outer Sheath |

| Flammability Class | NC | Halogen Free, Low Smoke, Fire Resistant |

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1 kV |

| Maximum Operating Temperature | 90°C |

| Conductor | Plain or Tinned Annealed Copper, Stranded |

| Insulation | Mica Glass Tape + Cross-Linked Polyethylene (XLPE) |

| Inner Sheath | Cross-linked Polyolefin (SHF2) |

| Screen | Collective Copper Screen |

| Armour | Braided Tinned/Plain Copper Wires |

| Fire Resistance | IEC 60331 |

| Flame Retardancy | IEC 60332-1 & IEC 60332-3-22 (Category A) |

| Halogen Content | IEC 60754-1 (Halogen Free) |

| Smoke Density | IEC 61034-2 (Low Smoke) |

| Core Range | 1 to 37 cores |

| Cross-Sectional Area | 0.75 mm² to 300 mm² |

Standards & Approvals

Manufactured to the highest international standards for fire safety, marine application, and material performance:

-

IEC 60092-350, 353: Electrical installations in ships – Design.

-

IEC 60228: Conductors of insulated cables.

-

IEC 60092-360: Insulating and sheathing materials.

-

IEC 60331: Tests for fire resistant characteristics.

-

IEC 60332-1 & -3-22: Tests for flame retardancy.

-

IEC 60754-1: Test on gases evolved during combustion (Halogen Free).

-

IEC 61034-2: Measurement of smoke density (Low Smoke).

Typical Applications

-

Marine & Offshore: Critical emergency circuits in engine rooms, machinery spaces, and on vessels/platforms where higher ambient temperatures, vibration, or the need for a flexible, corrosion-proof armor are present. Ideal for emergency generator feeds, fire pump power, and control circuits for safety systems.

-

Industrial & High-Temperature Zones: Power supply for essential and safety systems in industrial plants (e.g., power generation, chemical processing) where localized higher temperatures or mechanical stress on the cable necessitate a more robust, heat-resistant sheath material (SHF2) combined with fire survival capability and flexible armor.