Product Overview

The CJPJP95/SC represents the pinnacle of protection for marine and industrial power cabling, designed for extreme environments where maximum mechanical durability, superior chemical/thermal resistance, and essential fire safety are non-negotiable. This cable combines a robust galvanized steel wire braid armor for ultimate tensile and crush resistance with a comprehensive dual-layer sheath of Cross-linked Polyolefin (SHF2), providing an unmatched barrier against heat deformation, abrasion, oils, and harsh chemicals. As a fully shielded solution with XLPE insulation, it delivers reliable, interference-free power for the most critical and demanding fixed installations.

Key Features & Benefits

-

Ultimate Mechanical & Environmental Protection: Features a high-strength galvanized steel wire braid armor for maximum crush and impact resistance, combined with a double-layer SHF2 cross-linked sheath that offers exceptional thermal stability and resistance to deformation, chemicals, and abrasion.

-

Superior Thermal Performance: Both inner and outer sheaths utilize Cross-linked Polyolefin (SHF2), which maintains integrity and performance at higher temperatures and under mechanical stress far better than standard thermoplastic materials.

-

Comprehensive Fire Safety: All polymeric components are Halogen-Free and Low-Smoke (LSZH), drastically reducing the emission of toxic/corrosive gases and smoke density to enhance evacuation safety and protect equipment.

-

Reliable & Stable Power Delivery: XLPE (Cross-Linked Polyethylene) insulation ensures excellent dielectric properties and long-term thermal endurance for continuous operation at 90°C.

-

Effective EMI/RFI Shielding: The integrated collective copper screen minimizes electromagnetic and radio-frequency interference, ensuring signal integrity for sensitive power and control systems.

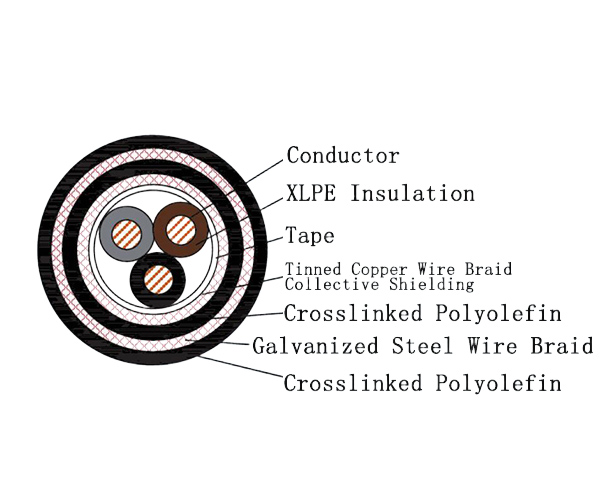

Cable Construction

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned or Plain Stranded Annealed Copper Wire (IEC 60228) |

| Insulation | J | Cross-Linked Polyethylene (XLPE) |

| Inner Sheath | PJ | Cross-linked Polyolefin (SHF2) - Halogen Free, Low Smoke |

| Screen | P | Collective Copper Screen |

| Armour | 9 | Braid of Galvanized Steel Wires |

| Outer Sheath | 5 | Cross-linked Polyolefin (SHF2) - Halogen Free, Low Smoke |

| Flammability Class | SC | Halogen Free, Low Smoke, Flame Retardant |

| Sheath Colour | / | Standard Black (Other colours on request) |

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1 kV |

| Maximum Operating Temperature | 90°C |

| Conductor | Plain or Tinned Annealed Copper, Stranded |

| Insulation | Cross-Linked Polyethylene (XLPE) |

| Inner & Outer Sheath | Cross-linked Polyolefin (SHF2) |

| Screen | Collective Copper Screen |

| Armour | Braided Galvanized Steel Wires |

| Flame Retardancy | IEC 60332-1 & IEC 60332-3-22 (Category A) |

| Core Range | 1 to 37 cores |

| Cross-Sectional Area | 0.75 mm² to 300 mm² |

Standards & Approvals

Manufactured to meet the stringent requirements of the following international standards:

-

IEC 60092-350, 353: Electrical installations in ships – General construction and test methods.

-

IEC 60228: Conductors of insulated cables.

-

IEC 60092-360: Insulating and sheathing materials.

-

IEC 60332-1: Test for vertical flame propagation for a single wire/cable.

-

IEC 60332-3-22: Test for vertical flame spread of bunched cables – Category A.

Typical Applications

-

Marine & Offshore: Critical main power distribution, feeder circuits, and essential systems on ships, oil & gas platforms, and in shipyards where cables are exposed to severe mechanical abuse, high temperatures, and corrosive environments.

-

Heavy Industrial & Mining: Primary power supply in the most demanding industrial settings such as underground mining, mineral processing, heavy metallurgy, and large-scale material handling where extreme mechanical protection, chemical resistance, and durability are paramount.