Product Overview

The CJPJP90/SC is a heavy-duty marine power cable engineered for demanding applications where superior mechanical strength must be combined with enhanced thermal and chemical resistance. Its construction is defined by a Cross-linked Polyolefin (SHF2) inner sheath for excellent heat and deformation resistance, and a rugged galvanized steel wire braid armor for maximum protection against crushing and impact. Designed without an outer sheath, this cable is optimized for installations where the robust steel armor serves as the primary protective layer, offering a reliable and durable solution for the toughest marine and industrial environments.

Key Features & Benefits

-

High-Strength Steel Armor: A braided armor of galvanized steel wires provides exceptional tensile strength and crush resistance, ideal for exposed runs or areas with significant mechanical hazards.

-

Thermally Enhanced Inner Sheath: The Cross-linked Polyolefin (SHF2) inner sheath offers superior resistance to high temperatures and mechanical stress compared to standard thermoplastics, ensuring core integrity in demanding conditions.

-

Essential Fire Safety: All polymeric materials are Halogen-Free and Low-Smoke (LSZH), minimizing the emission of corrosive/toxic gases and reducing smoke density for enhanced personnel safety.

-

Robust Electrical Performance: XLPE (Cross-Linked Polyethylene) insulation provides stable dielectric properties and thermal endurance for continuous operation at temperatures up to 90°C.

-

Effective EMI Protection: The collective copper screen shields against electromagnetic interference, ensuring the integrity of power and control signals.

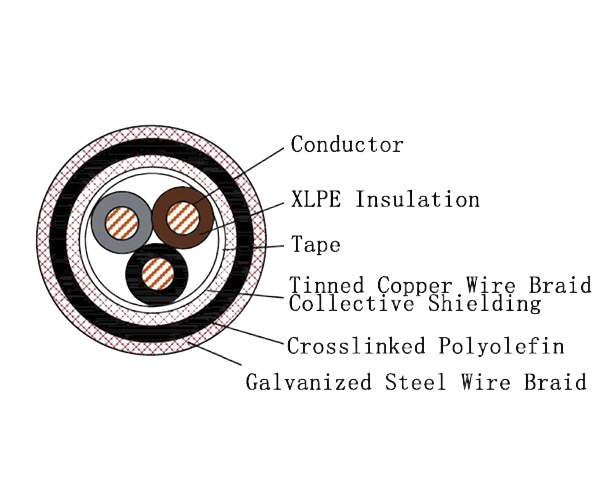

Cable Construction

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned or Plain Stranded Annealed Copper Wire (IEC 60228) |

| Insulation | J | Cross-Linked Polyethylene (XLPE) |

| Inner Sheath | PJ | Cross-linked Polyolefin (SHF2) - Halogen Free, Low Smoke |

| Screen | P | Collective Copper Screen |

| Armour | 9 | Braid of Galvanized Steel Wires |

| Outer Sheath | 0 | Without Outer Sheath |

| Flammability Class | SC | Halogen Free, Low Smoke, Flame Retardant |

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1 kV |

| Maximum Operating Temperature | 90°C |

| Conductor | Plain or Tinned Annealed Copper, Stranded |

| Insulation | Cross-Linked Polyethylene (XLPE) |

| Inner Sheath | Cross-linked Polyolefin (SHF2) |

| Screen | Collective Copper Screen |

| Armour | Braided Galvanized Steel Wires |

| Outer Protection | Galvanized Steel Wire Armor (No outer sheath) |

| Flame Retardancy | IEC 60332-1 & IEC 60332-3-22 (Category A) |

| Core Range | 1 to 37 cores |

| Cross-Sectional Area | 0.75 mm² to 300 mm² |

Standards & Approvals

Manufactured in full compliance with international marine and safety standards:

-

IEC 60092-350, 353: Electrical installations in ships – General construction and test methods.

-

IEC 60228: Conductors of insulated cables.

-

IEC 60092-360: Insulating and sheathing materials.

-

IEC 60332-1: Test for vertical flame propagation for a single wire/cable.

-

IEC 60332-3-22: Test for vertical flame spread of bunched cables – Category A.

Typical Applications

-

Marine & Offshore: Fixed power installations on ships and offshore platforms where cables are routed in areas prone to high mechanical stress, impact, or crushing (e.g., decks, bulkheads, shafts) and where the enhanced heat resistance of the SHF2 sheath is beneficial.

-

Heavy Industrial: Primary power feeds in mining, heavy machinery, quarrying, and industrial plants where extreme mechanical protection is the primary concern and the cable is installed in a way that protects the steel armor from prolonged direct exposure to corrosive elements.