Product Overview

The CJPJP85/SC is a premium-grade, fully cross-linked marine power cable designed for the most demanding environments where exceptional thermal stability, mechanical durability, and flexibility are required. It distinguishes itself by utilizing Cross-linked Polyolefin (SHF2) for both its inner and outer sheaths, providing superior resistance to heat deformation, cracking, and mechanical stress compared to standard thermoplastic sheaths. Combined with XLPE insulation, a collective screen, and a flexible tinned copper wire braid armor, this cable offers an optimal balance of long-term reliability, safety, and ease of installation in dynamic or high-stress applications.

Key Features & Benefits

-

Full SHF2 Cross-linked Sheathing: Both inner and outer sheaths are made of Cross-linked Polyolefin (SHF2), offering maximum resistance to high temperatures, deformation, and mechanical damage. This ensures outstanding long-term integrity in harsh conditions.

-

Flexible & Corrosion-Resistant Armor: The braided armor of tinned copper wires provides excellent flexibility for easier pulling and routing, along with superior corrosion resistance in humid and salty marine atmospheres.

-

Comprehensive Fire Safety: All sheath and insulation materials are Halogen-Free and Low-Smoke (LSZH), significantly reducing toxic fumes and smoke density to enhance personnel safety and equipment protection during fire incidents.

-

Reliable Electrical Performance: XLPE (Cross-Linked Polyethylene) insulation guarantees stable electrical characteristics and thermal endurance for continuous operation at 90°C.

-

Effective EMI/RFI Shielding: The integrated collective copper screen protects against electromagnetic and radio-frequency interference, ensuring clean power transmission for sensitive onboard systems.

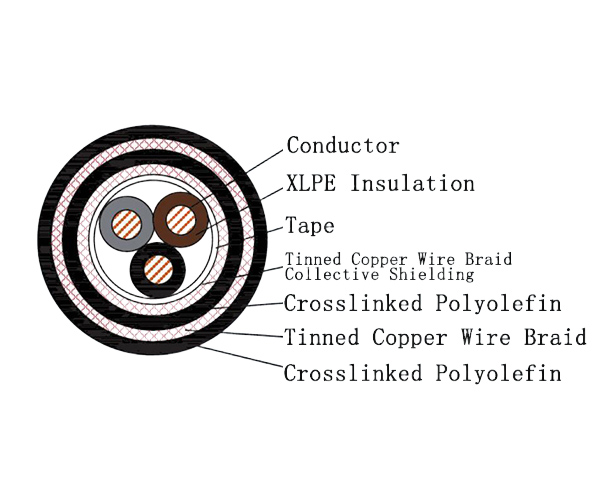

Cable Construction

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned or Plain Stranded Annealed Copper Wire (IEC 60228) |

| Insulation | J | Cross-Linked Polyethylene (XLPE) |

| Inner Sheath | PJ | Cross-linked Polyolefin (SHF2) - Halogen Free, Low Smoke |

| Screen | P | Collective Copper Screen |

| Armour | 8 | Braid of Tinned or Plain Copper Wires |

| Outer Sheath | 5 | Cross-linked Polyolefin (SHF2) - Halogen Free, Low Smoke |

| Flammability Class | SC | Halogen Free, Low Smoke, Flame Retardant |

| Sheath Colour | / | Standard Black (Other colours on request) |

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1 kV |

| Maximum Operating Temperature | 90°C |

| Conductor | Plain or Tinned Annealed Copper, Stranded |

| Insulation | Cross-Linked Polyethylene (XLPE) |

| Inner & Outer Sheath | Cross-linked Polyolefin (SHF2) |

| Screen | Collective Copper Screen |

| Armour | Braided Tinned/Plain Copper Wires |

| Flame Retardancy | IEC 60332-1 & IEC 60332-3-22 (Category A) |

| Core Range | 1 to 37 cores |

| Cross-Sectional Area | 0.75 mm² to 300 mm² |

Standards & Approvals

This cable is manufactured in full compliance with the following international marine and safety standards:

-

IEC 60092-350, 353: Electrical installations in ships – General construction and test methods.

-

IEC 60228: Conductors of insulated cables.

-

IEC 60092-360: Insulating and sheathing materials.

-

IEC 60332-1: Test for vertical flame propagation for a single wire/cable.

-

IEC 60332-3-22: Test for vertical flame spread of bunched cables – Category A.

Typical Applications

-

Marine & Offshore: Critical power and control circuits in high-temperature zones (e.g., engine rooms, near exhausts), on moving machinery, or in areas subject to frequent vibration and flexing on ships, drilling rigs, and offshore platforms.

-

Heavy Industrial: Power supply and distribution in industrial plants with high ambient temperatures, significant mechanical stress, or where cables are exposed to chemicals and abrasion, such as in metallurgy, heavy machinery, and certain areas of power generation facilities.