Product Overview

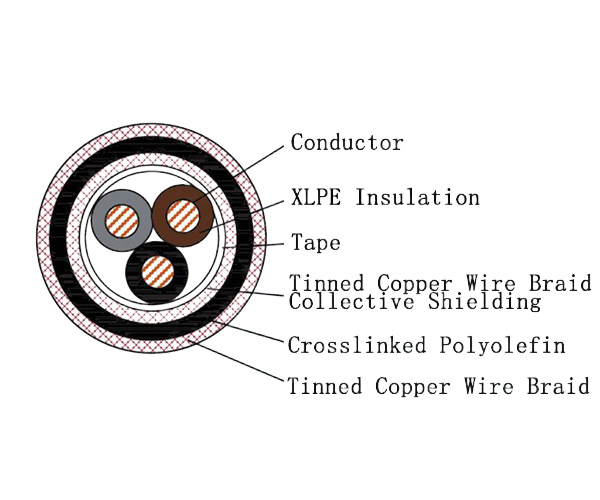

The CJPJP80/SC is a specialized marine power cable designed for applications requiring a combination of enhanced thermal/mechanical performance from the inner sheath and flexible, corrosion-resistant armor. Its key feature is the use of a Cross-linked Polyolefin (SHF2) inner sheath, which offers superior temperature and deformation resistance compared to standard thermoplastic sheaths. Combined with XLPE insulation, a collective screen, and a tinned copper wire braid armor, this cable provides a reliable and durable solution for dynamic or fixed installations where both electrical integrity and mechanical flexibility are critical.

Key Features & Benefits

-

Enhanced Inner Sheath: Features a Cross-linked Polyolefin (SHF2) inner sheath, providing improved resistance to heat deformation, cracking, and mechanical stress over standard materials, ensuring long-term integrity.

-

Flexible & Corrosion-Resistant Armor: Braided armor made of tinned copper wires offers excellent flexibility, ease of termination, and inherent corrosion resistance, making it ideal for marine atmospheres.

-

Superior Fire Safety: All polymeric materials are Halogen-Free and Low-Smoke (LSZH), minimizing toxic gas emission and smoke density to enhance safety during fire incidents.

-

Stable Electrical Core: XLPE insulation ensures high dielectric strength and thermal stability for continuous operation at 90°C.

-

Effective EMI Shielding: The collective copper screen protects against electromagnetic interference, safeguarding signal integrity for power and sensitive control circuits.

Cable Construction

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned or Plain Stranded Annealed Copper Wire (IEC 60228) |

| Insulation | J | Cross-Linked Polyethylene (XLPE) |

| Inner Sheath | PJ | Cross-linked Polyolefin (SHF2) - Halogen Free, Low Smoke |

| Screen | P | Collective Copper Screen |

| Armour | 8 | Braid of Tinned or Plain Copper Wires |

| Outer Sheath | 0 | Without Outer Sheath |

| Flammability Class | SC | Halogen Free, Low Smoke, Flame Retardant |

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1 kV |

| Maximum Operating Temperature | 90°C |

| Conductor | Plain or Tinned Annealed Copper, Stranded |

| Insulation | Cross-Linked Polyethylene (XLPE) |

| Inner Sheath | Cross-linked Polyolefin (SHF2) |

| Screen | Collective Copper Screen |

| Armour | Braided Tinned/Plain Copper Wires |

| Outer Protection | None (Armor serves as the protective layer) |

| Flame Retardancy | IEC 60332-1 & IEC 60332-3-22 (Category A) |

| Core Range | 1 to 37 cores |

| Cross-Sectional Area | 0.75 mm² to 300 mm² |

Standards & Approvals

Manufactured to comply with key international marine and safety standards:

-

IEC 60092-350, 353: Electrical installations in ships – General construction and test methods.

-

IEC 60228: Conductors of insulated cables.

-

IEC 60092-360: Insulating and sheathing materials.

-

IEC 60332-1: Test for vertical flame propagation for a single wire/cable.

-

IEC 60332-3-22: Test for vertical flame spread of bunched cables – Category A.

Typical Applications

-

Marine & Offshore: Power and control circuits in engine rooms, machinery spaces, and on moving equipment aboard ships and platforms where higher ambient temperatures, vibration, and the need for a flexible, corrosion-proof armor are present.

-

Industrial: Applications in industrial plants, such as power generation or chemical processing, where localized higher temperatures or mechanical stress on the cable necessitate a more robust inner sheath material, combined with the need for flexible EMI-shielded and grounded cable design.