CJV92/SA XLPE Insulated Armored Marine Power Cable

Product Overview

The CJV92/SA represents a fully protected marine power cable solution, combining galvanized steel wire armor with a protective PVC outer sheath. Designed for the most demanding fixed installations, it delivers maximum durability for power, lighting, and control circuits on offshore platforms and in extreme industrial environments such as metallurgy, chemical processing, power plants, and mining.

Key Features

-

Maximum Mechanical Protection: Features galvanized steel wire braid armor for superior resistance to crushing, impact, and tensile stress.

-

Complete Environmental Seal: The additional PVC outer sheath over the armor provides excellent protection against moisture, oils, chemicals, and corrosion.

-

XLPE Insulation: Ensures high thermal endurance (up to 90°C) and reliable electrical performance.

-

Flame Retardant Design: Complies with IEC 60332-1 and IEC 60332-3-22 for critical fire safety applications.

-

Comprehensive Range: Available in a wide range from 0.75 mm² to 300 mm², with 1 to 37 cores.

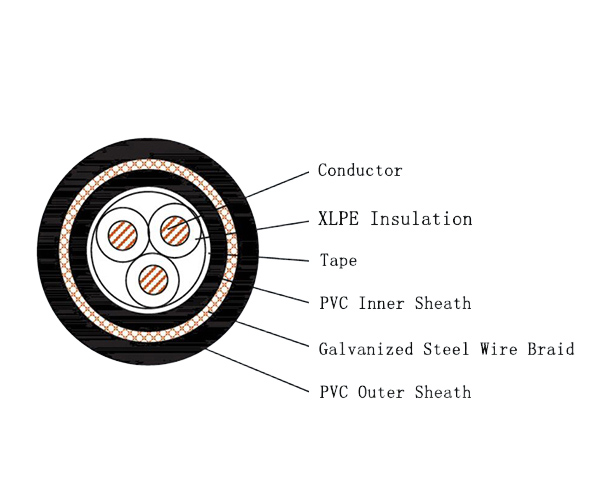

Construction Details

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned/Plain Stranded, Annealed Copper Wire |

| Insulation | J | XLPE Insulated |

| Inner Sheath | V | PVC |

| Armor | 9 | Galvanized Steel Wire Braid |

| Outer Sheath | 2 | PVC Outer Sheath |

| Outer Sheath Color | / | Black or other Color |

| Flammability | SA | Bunched Cables Flame Retardant |

Technical Specifications

-

Rated Voltage: 0.6/1 kV

-

Maximum Continuous Operating Temperature: 90°C

-

Conductor Cross-Sectional Area Range: 0.75 mm² to 300 mm²

-

Number of Cores: 1 to 37 Cores

Applicable Standards

-

IEC 60092-350, 353 – Design

-

IEC 60228 – Conductors

-

IEC 60092-360 – Insulation and Sheath

-

IEC 60332-1 – Test for vertical flame propagation for a single insulated wire/cable

-

IEC 60332-3-22 – Test for vertical flame spread of bunched cables (Category A)

Typical Applications

-

Offshore oil & gas platforms (both power and critical control systems)

-

Shipboard installations in areas with high risk of mechanical damage and corrosion

-

Coastal and harbor infrastructure

-

Heavy industrial plants, mining, and chemical facilities requiring maximum cable durability