Product Overview

Our Festoon System Communications Bus Coding Cable is specifically engineered for trailer communications systems in port equipment and control systems requiring high mechanical stress resistance and high-frequency alternating bending operation.

Key Applications

-

Trailer communications systems of port equipment

-

High mechanical stress control systems

-

High frequency alternating bending operations

-

Festoon systems requiring reliable data transmission

-

Industrial communication bus applications

Technical Specifications

-

Rated Voltage: U₀/U 0.6/1 kV

-

Temperature Rating:

-

Long-term working temperature: 90°C

-

Minimum operating temperature: -35°C

-

-

Bending Radius: Minimum 6× cable diameter (D)

-

Environmental Resistance: Abrasion, ozone, oil, UV radiation, and moisture resistant

-

Flame Retardant: Yes

-

Construction: EPR insulation with CR inner and outer sheathing

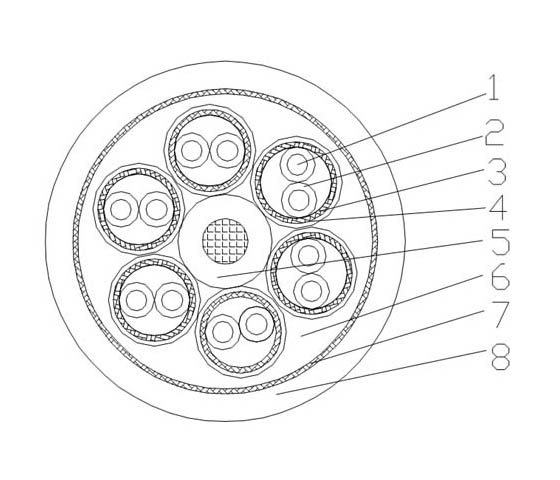

Cable Construction

-

Copper wire Conductor

-

EPR Insulation

-

Braid Screen

-

Defender layer

-

Reinforced Core

-

Inner Sheath

-

Braid reinforced layer

-

CR Outer Sheath

Color Coding: Core is black with white consecutive numbering; sheath is black

Product Code System

-

G: Cable for Port machinery

-

YD: Cable for Festoon systems

-

S: Twisted Pair Shielded

-

E: EPR Insulation

-

F: CR Sheath

-

R: Flexible Conductors

-

J: Aramid fiber reinforced

Technical Specifications Table

| Nominal Cross Section (mm²) | Construction (mm) | Nom. OD of Cable (mm) | Max. OD of Cable (mm) | Ref. Weight of Cable (Kg/km) | Max. Load (N) |

|---|---|---|---|---|---|

| 4×2×0.5 | 4×2×16/0.20 | 23.6 | 26.0 | 560 | 140 |

| 6×2×0.5 | 6×2×16/0.20 | 26.8 | 29.5 | 850 | 160 |

| 4×2×1 | 4×2×32/0.20 | 30.5 | 31.5 | 862 | 150 |

| 6×2×1 | 6×2×32/0.20 | 32.0 | 33.5 | 1200 | 180 |

Features & Benefits

-

High Flexibility: Designed for high-frequency alternating bending operations

-

Environmental Protection: Comprehensive resistance to abrasion, ozone, oil, UV, and moisture

-

Temperature Resilience: Stable performance from -35°C to 90°C

-

Flame Retardant: Enhanced safety characteristics

-

EMC Performance: Braid screen for reliable communications signal integrity

-

Mechanical Durability: Reinforced construction for high-stress environments

-

Color Coding: Clear identification with black cores and white numbering

Service Conditions

-

Suitable for outdoor use in harsh environmental conditions

-

Designed for continuous operation in high mechanical stress applications

-

Compatible with festoon systems and port equipment communications

-

Rated for both power and data transmission applications

Note: All technical specifications are based on standard manufacturing conditions. Consult our technical team for specific application requirements and custom solutions.