Product Overview

NSSHOEU Rubber Insulated Mining Flexible Cable is engineered for demanding mining applications requiring exceptional mechanical strength and flexibility. Developed specifically for open pit mines and underground mining operations, this cable withstands high mechanical loads while providing reliable power supply to motors and mobile equipment in harsh industrial environments.

Key Features & Benefits

-

Superior Mechanical Strength: Designed to withstand very high mechanical loads in mining applications

-

Enhanced Flexibility: Class 5 annealed copper conductors ensure excellent flexibility for mobile equipment

-

Environmental Resistance: Suitable for dry, damp, and outdoor environments including explosion hazard areas

-

Specialized Screening: Three of six cores are screened with tinned copper wires for specific application requirements

-

Durable Construction: PCP (Polychloroprene) sheath provides excellent mechanical and environmental protection

-

Comprehensive Compliance: Meets DIN VDE 0118-2, DIN VDE 0168, and other relevant mining standards

Applications

Specifically designed for demanding mining and industrial applications:

-

Underground Mining: Power supply cables for motors and distribution boards in underground mines

-

Open Cast Mining: Flexible operation in open pit mining applications

-

Tunnel Construction: Power distribution in tunnel building applications

-

Quarry Operations: Heavy-duty applications in quarries and similar environments

-

Mobile Equipment: Power supply to motors and other mobile equipment in industrial settings

-

Explosion Hazard Areas: Suitable for use in classified hazardous locations

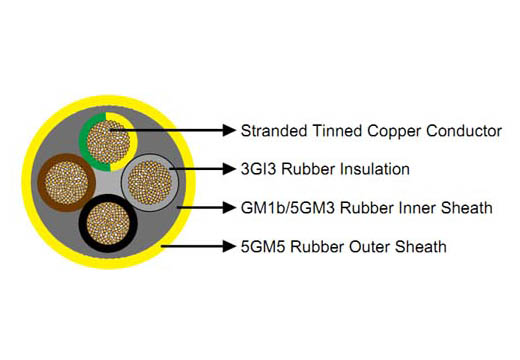

Construction

Robust Construction for Mining Applications:

-

Conductors: Annealed flexible copper, class 5

-

Insulation: EPR (Ethylene propylene rubber)

-

Core Identification: Coloured cores with printed numbers

-

Bedding: EPR (Ethylene propylene rubber)

-

Screen: TCW (Tinned copper wires) - Only 3 of the 6 cores are screened

-

Sheath/Jacket: PCP (Polychloroprene)

Standards Compliance

Applied Standards & Certifications:

-

DIN VDE 0250 Part 812: Rubber insulated cable NSSHOU

-

IEC 60332: Tests on electric cables under fire conditions

-

IEC 60811-2-1: Ozone resistance, hot set and mineral oil immersion tests

-

VDE 0473 Part 811-2-1: Resistance to oil

-

VDE 0482 Part 332-1-2: Behaviour in case of fire

-

VDE 0293: Identification of cores for cables

-

VDE 0298 Part 4: Current carrying capacity

Specifications

Detailed Technical Specifications:

| Cores × Area | Approx. Outer Diameter (mm) | Approx. Weight (kg/km) |

|---|---|---|

| 1×16 | 12.0 | 260 |

| 1×25 | 15.0 | 390 |

| 1×35 | 16.5 | 500 |

| 1×50 | 18.5 | 680 |

| 1×70 | 20.5 | 900 |

| 1×95 | 23.5 | 1150 |

| 1×120 | 26.0 | 1440 |

| 1×150 | 28.0 | 1750 |

| 1×185 | 32.0 | 2180 |

| 1×240 | 35.0 | 2790 |

| 3G1.5 | 13.5 | 200 |

| 3G2.5 | 15.0 | 260 |

| 4G1.5 | 14.5 | 230 |

| 4G2.5 | 17.5 | 360 |

| 4G4 | 20.0 | 470 |

| 4G6 | 21.5 | 580 |

| 4G10 | 26.0 | 950 |

| 4G16 | 32.0 | 1400 |

| 4G25 | 37.0 | 2000 |

| 4G35 | 40.5 | 2700 |

| 4G50 | 46.5 | 3700 |

| 5G1.5 | 15.5 | 280 |

| 5G2.5 | 18.5 | 420 |

| 5G4 | 21.0 | 550 |

| 5G6 | 24.5 | 740 |

| 5G10 | 28.0 | 1100 |

| 5G16 | 32.0 | 1720 |

| 7G2.5 | 20.0 | 600 |

| 12G2.5 | 26.0 | 860 |

| 18G2.5 | 31.0 | 1240 |

Key Advantages

-

Proven Reliability: Specifically developed for special requirements in open pit and underground mining

-

Enhanced Safety: Complies with German mining standards DIN VDE 0118-2 and DIN VDE 0168

-

Optimized Design: Concentric earth conductor placement in small cross-sections and multi-core configurations

-

Durable Performance: Withstands extreme mechanical stress and environmental challenges

-

Flexible Application: Suitable for both fixed installation and flexible operation in various mining scenarios

-

Industry Compliance: Meets international standards for mining cable applications and safety requirements