Product Overview

NSGAFOEU Rubber Insulated Special Mining Cable is engineered for demanding applications in track-bound vehicles, buses, and mining installations requiring superior electrical performance and mechanical durability. Available in 1.8/3kV and 3.6/6kV ratings, this cable features EPR insulation and specialized construction to ensure reliable power distribution in both fixed and mobile mining applications.

Key Features & Benefits

-

High Voltage Rating: Suitable for 1.8/3kV and 3.6/6kV applications, including low-voltage switchboard connections

-

Enhanced Mechanical Protection: Specifically designed for higher mechanical stress in mining environments

-

Temperature Resilience: Operates in static conditions from -40°C to +80°C

-

Dual Sheath Options: Available with chlorinated rubber or halogen-free polymer compounds

-

Short-Circuit Protection: 3kV-rated cables ensure inherently short-circuit and earth-fault proof connections

-

Flexible Application: Suitable for fixed installation and mobile part connections

Applications

Specialized mining and industrial applications:

-

Track-Bound Vehicles: Power distribution in mining vehicles and transport systems

-

Bus Applications: Electrical systems in industrial and mining buses

-

Pipe and Duct Installation: Fixed installation in closed installation ducts and pipes

-

Mobile Equipment: Connection of mobile parts in mining operations

-

Heating Circuits: Specialized connection links for vehicle heating systems

-

Low-Voltage Switchboards: Inherently short-circuit proof connections

Construction

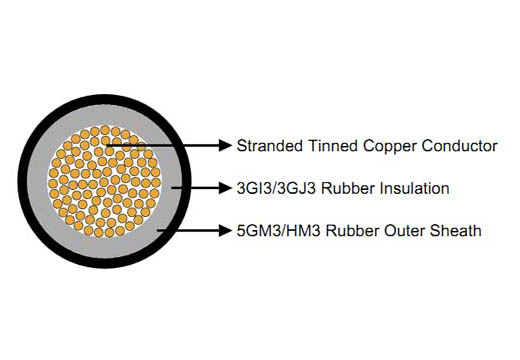

Advanced Construction for Special Applications:

-

Conductors: Stranded tinned copper conductor, class 5 (DIN VDE 0295/IEC 60228)

-

Inner Conductor Layer: Semi-conducting layer (for 6kV versions)

-

Insulation: EPR compound type 3GI3/3GJ3

-

Optional Screen: Tinned copper wires (for NSGAFCMOEU/NSHXAFCMOE)

-

Outer Sheath:

-

Chlorinated rubber type 5GM3, oil resistant and flame retardant (NSGAFOEU/NSGAFCMOEU)

-

Halogen-free polymer compound HM3, oil-resistant, flame retardant, low smoke (NSHXAFOE/NSHXAFOE)

-

Technical Data

Electrical Ratings:

-

Rated Voltage: U0/U 1.8/3 kV | 3.6/6 kV

Temperature Ratings:

-

Static Applications: -40°C to +80°C

-

Flexing Applications: -25°C to +80°C

Bending Radius Requirements:

-

NSGAFOEU, NSGAFCMOEU: 4 × cable diameter

-

NSHXAFOE, NSHXAFCMOE: 6 × cable diameter

Specifications

NSGAFOEU/NSHXAFOE 1.8/3kV Specifications:

| Number of Cores × Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. × mm² | mm | mm | kg/km |

| 1×1.5 | 5.7 | 7.0 | 50 |

| 1×2.5 | 6.0 | 7.5 | 60 |

| 1×4 | 6.8 | 9.0 | 80 |

| 1×6 | 7.3 | 9.5 | 100 |

| 1×10 | 8.7 | 11.0 | 160 |

| 1×16 | 10.0 | 13.0 | 230 |

| 1×25 | 12.4 | 15.0 | 340 |

| 1×35 | 13.4 | 16.5 | 430 |

| 1×50 | 14.9 | 18.0 | 580 |

| 1×70 | 16.6 | 20.5 | 780 |

| 1×95 | 19.3 | 24.0 | 1030 |

| 1×120 | 20.8 | 26.0 | 1270 |

| 1×150 | 23.0 | 28.0 | 1570 |

| 1×185 | 25.2 | 31.0 | 1900 |

| 1×240 | 28.1 | 34.5 | 2500 |

| 1×300 | 30.8 | 38.0 | 3000 |

| 1×400 | 40.0 | 34.6 | 4000 |

NSGAFOEU/NSHXAFOE 3.6/6kV Specifications:

| Number of Cores × Nominal Cross Section | Minimum Overall Diameter | Maximum Overall Diameter | Nominal Weight |

|---|---|---|---|

| No. × mm² | mm | mm | kg/km |

| 1×1.5 | 8.3 | 9.5 | 135 |

| 1×2.5 | 8.6 | 10.5 | 150 |

| 1×4 | 9.4 | 12.0 | 170 |

| 1×6 | 9.9 | 13.0 | 200 |

| 1×10 | 10.9 | 14.5 | 250 |

| 1×16 | 12.6 | 15.5 | 350 |

| 1×25 | 14.5 | 17.5 | 480 |

| 1×35 | 15.6 | 19.0 | 600 |

| 1×50 | 17.1 | 21.0 | 760 |

| 1×70 | 18.8 | 23.0 | 960 |

| 1×95 | 21.3 | 26.5 | 1240 |

| 1×120 | 23.2 | 28.5 | 1530 |

| 1×150 | 25.0 | 30.5 | 1790 |

| 1×185 | 26.8 | 33.0 | 2130 |

Key Advantages

-

Proven Reliability: Specifically designed for demanding mining and vehicle applications

-

Enhanced Safety: Multiple voltage ratings with inherent short-circuit protection

-

Durable Construction: EPR insulation and specialized sheathing for harsh environments

-

Flexible Design Options: Multiple cable types for different mechanical and environmental requirements

-

Comprehensive Size Range: Available from 1.5mm² to 400mm² in single-core configurations

-

Temperature Resilience: Maintains performance across wide temperature range from -40°C to +80°C