Product Overview

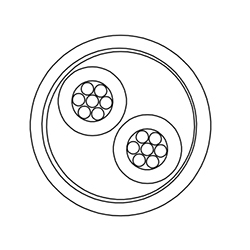

FA-DPY is a flame-retardant, double-core shipboard power cable rated at 0.6/1kV, designed for fixed installations on ships and offshore units. Featuring EP rubber insulation, PVC sheath, and tinned copper conductors, it delivers reliable performance in demanding marine environments.

Key Features

-

Rated Voltage: 0.6/1kV

-

Conductor: Double core, stranded tinned annealed copper (IEC 60228, Class 2)

-

Insulation: 85°C Ethylene Propylene Rubber (EPR)

-

Sheath: Black PVC (JIS C 3401)

-

Flame Retardancy: IEC 60332-1 & IEC 60332-3 Category A (FA-Type)

-

Cold Resistance: CSA 22.2 No.03 (-35°C Cold Type)

-

Core Identification: Black, White (for 2-core version)

Cable Construction

-

Conductor: Double core, stranded tinned annealed copper wires, Class 2 (JIS C 3410)

-

Insulation: 85°C EPR per IEC 60092-351

-

Cabling:

-

Insulated conductors cabled together

-

Flame retardant & non-hygroscopic fillers

-

Suitable tape applied on cabled core

-

-

Sheath: PVC, black color (JIS C 3401)

Technical Specifications

Construction Details

| Component | Code | Material & Standards |

|---|---|---|

| Conductor | D | Tinned annealed stranded copper, class 2 (IEC 60228) |

| Insulation | P | 85°C EPR (IEC 60092-351) |

| Sheath | Y | PVC (JIS C 3401) |

Core Identification

-

1 Core: Black

-

2 Core: Black, White

-

3 Core: Black, White, Red

-

Outer Sheath Color: Black

Certifications & Standards

-

JIS C 3410 (1999): Japanese Industrial Standard for shipboard cables

-

IEC 60332-1: Flame test for single vertical insulated wire/cable

-

IEC 60332-3 Category A: Flame retardancy for bunched cables (FA-Type)

-

CSA 22.2 No.03: Cold bend/impact test at -35°C (Cold Type)

Applications

-

Fixed electrical installations on all types of ships

-

Offshore platforms and drilling units

-

Marine power distribution systems

-

Coastal and marine industrial facilities

-

All locations requiring reliable shipboard power cables

Quality Assurance

-

Manufactured under strict quality control standards

-

Comprehensive testing for electrical and mechanical properties

-

Corrosion-resistant construction for extended service life

-

Compliance with international marine safety requirements

-

Documentation and certification provided with shipments