Product Overview

The CEVR90/NA is a heavy-duty, fire-resistant marine flexible power cable designed for critical safety circuits that demand both certified circuit integrity during a fire and superior mechanical strength. It combines durable Ethylene Propylene Rubber (EPR) insulation, a PVC inner sheath, and galvanized steel wire braid armor. This robust construction is engineered to ensure the continued operation of emergency and life-safety systems in the most physically demanding and high-risk environments on vessels, offshore installations, and in heavy industry.

Technical Specifications

-

Rated Voltage (U₀/U): 0.6/1 kV

-

Maximum Continuous Conductor Temperature: 90°C

-

Conductor: Tinned or Plain Stranded, Annealed Copper Wire (Class 5/6 flexible) (IEC 60228)

-

Available Cross-Sections: 0.75 mm² to 300 mm²

-

Core Configurations: 1 to 37 Cores

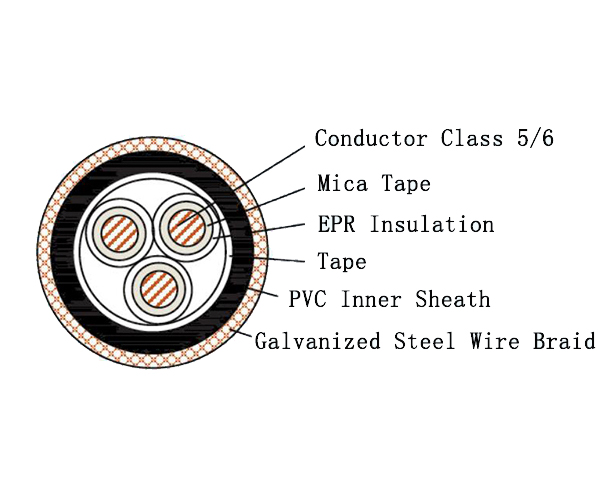

Cable Construction & Materials

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned/Plain Stranded, Annealed Copper Wire (Flexible Class 5/6) |

| Insulation | E | EPR insulated |

| Inner Sheath | V | PVC |

| Armor | 9 | Galvanized Steel Wire Braid |

| Outer Sheath | 0 | Without Outer Sheath |

| Flammability | NA | Fire Resistant |

Key Performance Characteristics

-

Certified Fire Resistance (IEC 60331): The cable is designed to maintain electrical circuit integrity and continue functioning for a specified period under direct flame exposure, which is critical for emergency power, lighting, alarm, and fire pump control circuits.

-

Maximum Mechanical Protection: The galvanized steel wire braid armor provides exceptional resistance to crushing, impact, abrasion, and rodent damage, protecting the critical fire-resistant core in exposed or hazardous routing paths.

-

Superior EPR Insulation: Ethylene Propylene Rubber (EPR) offers excellent dielectric properties, thermal stability, and long-term resistance to heat and moisture, ensuring reliable power transmission.

-

High Flexibility: Despite its heavy-duty armor, the use of flexible Class 5/6 conductors ensures the cable remains manageable for installation in complex cable trays and confined spaces.

-

Flame Retardant: Complies with IEC 60332-1 and IEC 60332-3-22, helping to inhibit the spread of flame along the cable run.

-

Corrosion-Resistant Armor: The galvanized coating on the steel wire provides protection against corrosion in humid and saline marine atmospheres.

Standards & Compliance

This cable is designed and tested in accordance with key international marine and fire safety standards:

-

IEC 60092-350, 353 (General construction and armor requirements)

-

IEC 60228 (Conductors)

-

IEC 60092-360 (Insulation and sheath materials)

-

IEC 60331 (Fire Resistance)

-

IEC 60332-1 & IEC 60332-3-22 (Flame retardancy tests)

Typical Applications

This armored fire-resistant cable is specified for the most critical circuits where operation during a fire and physical survivability are non-negotiable:

-

Marine & Offshore: Essential power feeds to emergency generators, fire pump power and control circuits, and critical alarm systems on ships and offshore platforms, especially in areas prone to physical damage.

-

Heavy Industry & Critical Infrastructure: Safety-critical power and control wiring in power generation plants, chemical facilities, mining, and heavy machinery where both fire resistance and high mechanical protection are required by safety protocols.