N2XSY, NA2XSY & NA2XS(F)2Y Medium Voltage XLPE Cables

Product Overview

Engineered for critical power distribution in industrial networks, these DIN VDE 0276-620-compliant MV cables deliver reliable performance across 6/10kV to 18/30kV systems. Featuring XLPE/TR-XLPE insulation and versatile constructions (copper/aluminum conductors, tape/wire screens, armored/unarmored), they excel in direct burial, duct, and harsh environments. Flame-retardant PVC/PE sheaths ensure safety per IEC/EN 60332-1-2.

Key Features & Benefits

-

Voltage Range: 6/10kV (Um=12kV), 12/20kV (Um=24kV), 18/30kV (Um=36kV)

-

Conductor Options: Copper (N2XSY) or Aluminum (NA2XSY) | 25–800mm²

-

Armor Versatility: Unarmored (N2XSY), Aluminum Wire Armor (NA2XSRY), Steel Tape Armor (N2XSEBY)

-

Extreme Resilience: -20°C to +70°C operational | 250°C short-circuit withstand

-

Easy Installation: 15×OD bending radius | Sunlight-resistant (with protection)

-

Certified Safety: CE, ISO 9001 | Flame-retardant per IEC/EN 60332-1-2

Technical Specifications

| Parameter | Specification | Standard |

|---|---|---|

| Rated Voltage | 6/10kV, 12/20kV, 18/30kV | DIN VDE 0276-620 |

| Conductor | Cu/Al Class 2 (compacted stranded) | EN 60228 |

| Insulation | XLPE or TR-XLPE (tree-retardant) | HD 620 |

| Screen | Copper tape (CTS) or wire (CWS) | IEC 60502-2 |

| Sheath | PVC/PE (flame-retardant) | IEC 60332-1-2 |

| Bending Radius | 15 × Cable Diameter | DIN VDE 0298 |

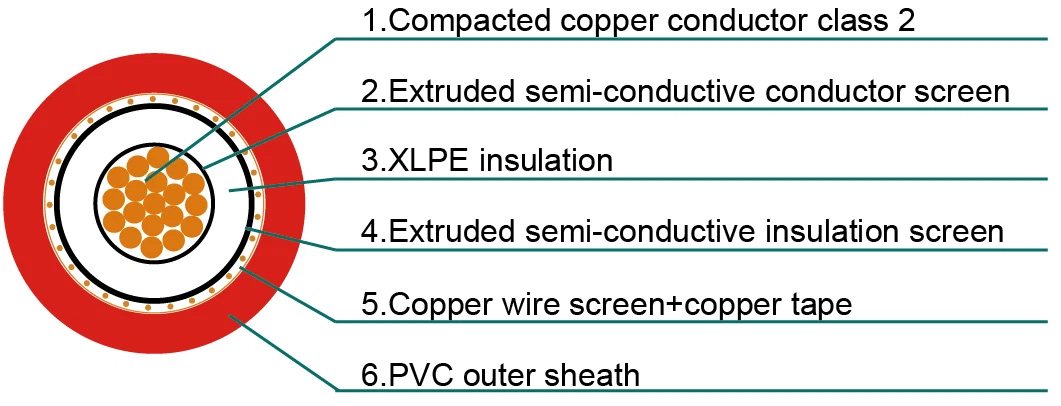

Cable Construction

Core Components:

-

Conductor:

-

Annealed compacted copper/aluminum (Class 2)

-

-

Conductor Screen:

-

Semi-conducting compound for电场 homogenization

-

-

Insulation:

-

XLPE or TR-XLPE (cross-linked polyethylene)

-

-

Insulation Screen:

-

Semi-conducting layer for termination ease

-

-

Metallic Screen:

-

CTS: Helical copper tape

-

CWS: Concentric copper wires

-

-

Armor (Optional):

-

Aluminum wire (AWA) or galvanized steel tape (STA/SWA)

-

-

Outer Sheath:

-

PVC (standard) or PE (UV/abrasion resistance)

-

Product Codes & Configurations

| Code | Construction | Description |

|---|---|---|

| N2XSY | Cu/XLPE/CTS/PVC | Unarmored copper, tape screen |

| NA2XSY | Al/XLPE/CTS/PVC | Unarmored aluminum, tape screen |

| N2XSRY | Cu/XLPE/CTS/PVC/AWA/PVC | Aluminum wire armor (AWA) |

| NA2XS(F)2Y | Cu/XLPE/CWS/PVC/SWA/PVC | Steel wire armor (SWA) + wire screen |

| N2XSEBY | Cu/XLPE/CTS/PVC/STA/PVC | Double steel tape armor (STA) |

All configurations available in triplex/parallel layouts on request.

Application Scenarios

-

Power Stations: Generator connections, substation feeders

-

Industrial Plants: High-load machinery (≥630mm² for 36kV systems)

-

Renewable Energy: Wind/solar farm collector networks

-

Underground Networks: Direct burial in corrosive soils (PE sheath recommended)

-

Harsh Environments: Chemical plants, mining (armored variants)

Engineering Selection Guide

| Requirement | Recommended Cable Code | Key Advantage |

|---|---|---|

| Cost-effective distribution | NA2XSY (Aluminum conductor) | 30% weight reduction vs. copper |

| High mechanical protection | N2XSEBY (steel tape armor) | Crush resistance for buried installations |

| Corrosive environments | N2XSRY (aluminum wire armor) | Saltwater/chemical resistance |

| Treeing-risk areas | NA2XS(F)2Y (TR-XLPE insulation) | Prevents dendritic degradation |

Current Ratings (Representative 12/20kV in Air)

| Size | Unarmored [A] | SWA Armored [A] |

|---|---|---|

| 150mm² | 405 | 380 |

| 240mm² | 520 | 485 |

| 400mm² | 650 | 605 |

Conditions: 30°C ambient, trefoil formation. Full tables available in datasheet.

Certifications & Packaging

-

Standards: DIN VDE 0276-620, HD 620, EN 60228, IEC/EN 60332-1-2

-

Certifications: CE, ISO 9001

-

Packaging: Fumigated steel-wood drums (1,000m/2,000m standard)

-

Customization: Sheath material (PVC/PE), armor type, screen configuration