Type P Power Cable (Armored & Unarmored)

Product Overview:

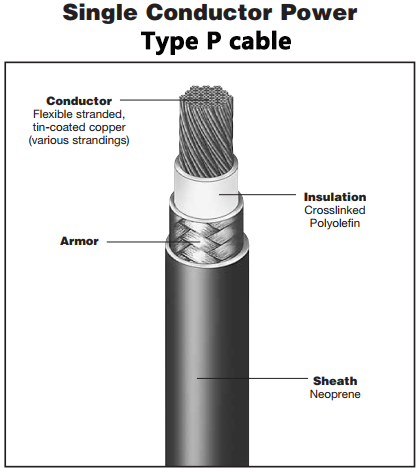

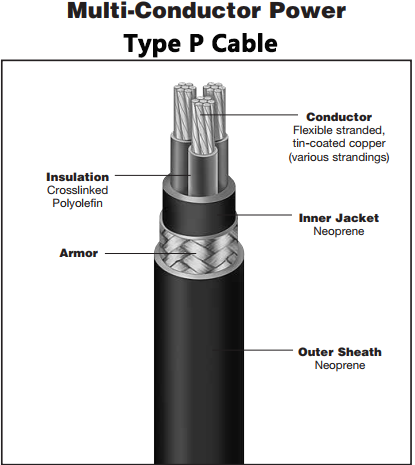

Engineered for extreme environments including offshore platforms, land-based drilling rigs, and harsh industrial sites, the Type P Power Cable delivers unmatched reliability, safety, and flexibility. Available in single-conductor (600V & 2000V) and multi-conductor (600V) configurations with optional armor (Bronze or Tinned Copper Braid), Type P cables withstand extreme temperatures, mechanical stress, moisture, and flame while meeting rigorous international standards.

Key Features & Benefits

-

Extreme Environment Resilience: Resists heat (+125°C), UV, moisture, and flames. Complies with UL 2225 Crush & Impact tests for Type MC-HL cables.

-

Arctic Performance: Heavy-Duty Arctic Grade Neoprene jacket passes -55°C cold bend and -40°C cold impact tests.

-

Superior Flexibility: Easy installation in confined spaces with no separator tape and easy-strip construction.

-

Corrosion Resistance: Tinned copper conductors (ASTM B33/B8/B172) enhance termination reliability in corrosive environments.

-

High-Temperature Insulation: Irradiation cross-linked Polyolefin (125°C) ensures thermal stability (UL/CSA 110°C operational).

-

Mechanical Protection: Optional Bronze Braid (Std.) or Tinned Copper Braid armor resists cuts/abrasion.

-

Clear Identification: Vivid IEEE 1580-compliant insulation colors (customizable).

Construction & Technical Specifications

| Feature | Single-Conductor Cable | Multi-Conductor Cable | Standard |

|---|---|---|---|

| Voltage Rating | 600V & 2000V | 600V | - |

| Conductor | Flexible Annealed Tinned Copper | Flexible Annealed Tinned Copper | ASTM B33, B8, B172 |

| Insulation | Cross-Linked Polyolefin, 125°C | Cross-Linked Polyolefin, 125°C | IEEE 1580 |

| Insulation Color | Custom (Req.), Std: Dark Gray | IEEE-45/UL 1309 Colors | IEEE 1580 |

| Fillers/Binder | N/A | Flame-Retardant Non-Hygroscopic Fillers; Non-Wicking Tape | - |

| Inner Jacket | N/A | Arctic Neoprene (UV Resistant) | - |

| Armor (Optional) | Bronze Braid (Std.), Tinned Copper (Opt.) | Bronze Braid (Std.), Tinned Copper (Opt.) | - |

| Outer Sheath | Arctic Neoprene (UV Resistant) | Arctic Neoprene (UV Resistant) | - |

| Temp. Rating | UL/CSA: 110°C; IEEE: 100°C | UL/CSA: 110°C; IEEE: 100°C | UL, CSA, IEEE |

| Certifications | UL 2225 (MC-HL), -55°C Bend, -40°C Impact | UL 2225 (MC-HL), -55°C Bend, -40°C Impact | UL 2225 |

Material Characteristics

-

Conductor: Tinned copper prevents oxidation in saltwater/chemical exposure.

-

Insulation: Thermoset polyolefin resists thermal degradation, flames, and environmental stress.

-

Armor: Metallic braid provides dynamic flex protection without rigidity.

-

Jacket: Arctic Neoprene resists oils, chemicals, ozone, UV, and freezing temperatures (-55°C).

Primary Application Scenarios

-

Offshore Platforms: Power distribution, winches, and lighting in corrosive marine environments.

-

Drilling Rigs: Drawworks, mud pumps, and generators exposed to oils/vibration.

-

Arctic Operations: Sub-zero power transmission in mining/industrial sites.

-

Hazardous Locations: UL 2225-compliant for MC-HL (Metal Clad Hazardous Location) installations.

-

Industrial Machinery: Flexible power feeds for heavy equipment.

Engineering Selection Guide

| Selection Factor | Recommendation |

|---|---|

| Mechanical Risk | Armored (Bronze/Tinned Copper) for impact/crush zones |

| Flexibility Needs | Unarmored for tight bends/conduit runs |

| Voltage | 2000V Single-conductor for high-voltage circuits |

| Color Coding | Specify during ordering (IEEE 45/UL 1309 for multi-conductor) |

| Ambient Temperature | Verify load vs. 100°C (IEEE) / 110°C (UL) rating |

| Cold Environments | Arctic Neoprene jacket mandatory below -40°C |