Product Overview

Heavy-Duty Flexible Power Cable for Rail & Mobile Equipment

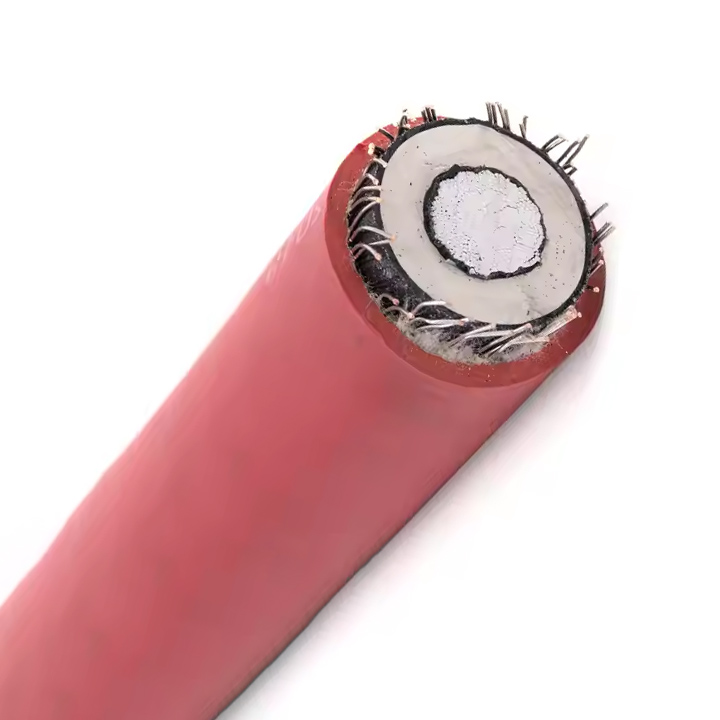

NSGAFOU 1.8/3kV cables feature Class 5 aluminum conductors with EPR/PCP double insulation, engineered for extreme mobility applications in rail transport. Compliant with VDE 0250-602, they deliver oil resistance, flame retardancy, and flexibility in temperatures from -40°C to +90°C.

Key Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 1.8/3kV (Um: 2.7kV) |

| Conductor | Class 5 Aluminum (IEC 60228, HD 383) |

| Insulation | EPR Type 3GI3 (DIN VDE 0207-20) |

| Sheath | PCP Type 5GM3 (DIN VDE 0207-21) |

| Temperature Range | Fixed: -40°C to +90°C • Mobile: -25°C to +90°C |

| Short-Circuit Rating | +200°C |

| Bending Radius | Fixed: 4×Ø • Mobile: 10×Ø |

Construction Details

-

Conductor: Class 5 flexible aluminum (IEC 60228)

-

Separator: Foil tape moisture barrier

-

Insulation: Ethylene-propylene rubber (EPR 3GI3)

-

Sheath: Chlorinated rubber compound (PCP 5GM3)

-

Core Identification: Standard black (custom colors available)

Technical Performance

Environmental Resistance

-

Oil Resistance: EN 60811-2-1 certified

-

Flame Retardant: IEC 60332-1-2 compliant

-

Weather Resistance: UV/ozone resistant

-

RoHS Compliance: Heavy metal-free

Mechanical Properties

| Application Type | Min. Bending Radius | Temp. Range |

|---|---|---|

| Fixed Installation | 4 × Cable Ø | -40°C to +90°C |

| Mobile Equipment | 10 × Cable Ø | -25°C to +90°C |

NSGAFOU Cable Specifications

| Ref. No. | Conductor (mm²) | Insul. Thick (mm) | Sheath Thick (mm) | O.D. (mm) | Weight (kg/km) | Ampacity* (A) | R/km (Ω) |

|---|---|---|---|---|---|---|---|

| NSGAFOU1.5 | 1×1.5 | 1.3 | 0.8 | 6.0 | 44 | 30 | 13.7 |

| NSGAFOU2.5 | 1×2.5 | 1.3 | 0.8 | 6.2 | 57 | 41 | 8.21 |

| NSGAFOU4 | 1×4 | 1.3 | 0.8 | 6.7 | 74 | 55 | 5.09 |

| NSGAFOU6 | 1×6 | 1.3 | 0.8 | 7.3 | 99 | 70 | 3.39 |

| NSGAFOU10 | 1×10 | 1.5 | 0.8 | 8.6 | 150 | 98 | 1.95 |

| NSGAFOU16 | 1×16 | 1.5 | 0.8 | 10.1 | 215 | 132 | 1.24 |

| NSGAFOU25 | 1×25 | 1.8 | 1.0 | 12.3 | 323 | 176 | 0.795 |

| NSGAFOU35 | 1×35 | 1.8 | 1.0 | 13.0 | 413 | 218 | 0.565 |

| NSGAFOU50 | 1×50 | 1.8 | 1.0 | 15.0 | 566 | 276 | 0.393 |

| NSGAFOU70 | 1×70 | 1.8 | 1.0 | 16.8 | 761 | 347 | 0.277 |

| NSGAFOU95 | 1×95 | 2.2 | 1.0 | 19.7 | 1,006 | 416 | 0.210 |

| NSGAFOU120 | 1×120 | 2.2 | 1.0 | 20.8 | 1,235 | 488 | 0.164 |

| NSGAFOU150 | 1×150 | 2.5 | 1.2 | 23.6 | 1,576 | 566 | 0.132 |

| NSGAFOU185 | 1×185 | 2.4 | 1.2 | 25.7 | 1,853 | 644 | 0.108 |

| NSGAFOU240 | 1×240 | 2.6 | 1.2 | 29.4 | 2,479 | 775 | 0.0817 |

| NSGAFOU300 | 1×300 | 2.8 | 1.2 | 31.9 | 2,953 | 898 | 0.0654 |

| NSGAFOU400 | 1×400 | 3.1 | 1.4 | 34.5 | 3,853 | 1,060 | 0.0495 |

| NSGAFOU500 | 1×500 | 3.4 | 1.4 | 43.2 | 4,974 | 1,250 | 0.0391 |

| *Current carrying capacity in air at 30°C ambient |

Applications

-

Rail Transport:

-

Train power distribution

-

Underground coaches & trams

-

Pantograph connections

-

-

Mobile Equipment:

-

Cranes & hoists

-

Mining machinery

-

Portable generators

-

-

Fixed Installations:

-

Substation feeders

-

Industrial motor circuits

-

Standards Compliance

Primary Standard: DIN VDE 0250-602

Material Standards:

-

DIN VDE 0207-20 (EPR insulation)

-

DIN VDE 0207-21 (PCP sheath)

Performance Standards: -

IEC 60332-1-2 (Flame retardancy)

-

EN 60811-2-1 (Oil resistance)

Product Advantages

1. Optimized for Dynamic Use

-

Class 5 aluminum conductor maintains flexibility through 1M+ bend cycles

-

PCP sheath withstands hydraulic oils and abrasives

2. Environmental Resilience

-

UV/ozone resistance for outdoor exposure

-

-40°C cold flexibility (fixed installations)

3. Safety Compliance

-

Flame propagation prevention (IEC 60332-1-2)

-

Halogen-free smoke emission

4. Economic Efficiency

-

40% weight reduction vs. copper equivalents

-

30% lower installation costs

Engineering Notes:

-

Specify NSGAFOU for: Pantograph wiring, third-rail systems, and moving machinery

-

Use armored variants for high-abrasion zones (tunnel installations)