Heavy-Duty 2000V Mining Cable (4×3 AWG + 4×10 AWG Configuration)

Engineered for Demanding Mine & Industrial Applications

This UL/MSHA-certified 2000V trailing cable delivers reliable power in extreme conditions for:

-

Continuous miners, shuttle cars, and cutting machines

-

Drills, conveyors, and pump systems

-

Open-pit and underground mining operations

-

Safety-critical applications requiring ground-check monitoring

Certifications & Compliance

-

UL Listed: File E482608

-

MSHA Approved: Compliant with mine safety standards

-

Voltage Rating: 2000V

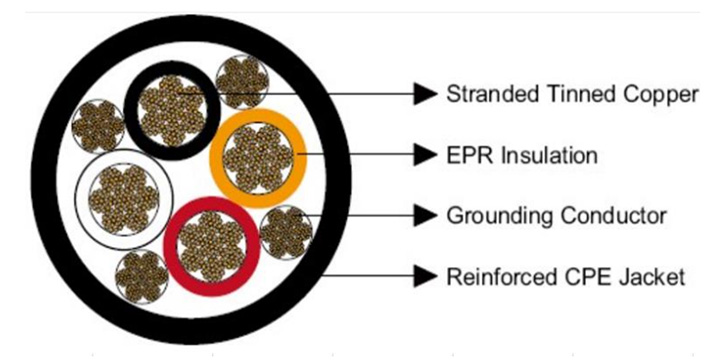

Robust Construction

-

Phase Conductors: 4 × 3 AWG

-

Annealed stranded tinned copper (259 strands)

-

-

Separator: Non-hygroscopic tape

-

Insulation: Ethylene-Propylene Rubber (EPR)

-

Phase Colors: Black/White/Red/Orange

-

-

Ground Conductors: 4 × 10 AWG

-

Tinned copper with green EPR insulation

-

-

Assembly: Precision-cabled round core

-

Filler: Rubber-filled binder tape

-

Jacket: Heavy-duty thermosetting CPE (Black)

Key Performance Specifications

| Parameter | Specification |

|---|---|

| Conductor Temperature | 90°C continuous |

| Ambient Temperature | 30°C rated |

| Oil Resistance | Excellent (MIL-DTL-24643) |

| UV Resistance | ASTM G154 compliant |

| Nom. Insul. Thickness | 1.52 mm |

| Approx. Diameter | 32.8 mm |

| Approx. Weight | 2,115 kg/km |

| Ampacity | 106 A |

Technical Data Sheet: 4×3 AWG + 4×10 AWG Configuration

| Phase Conductors | Ground Conductors | Insulation Thickness | Outer Diameter | Weight | Ampacity |

|---|---|---|---|---|---|

| 4 × 3 AWG | 4 × 10 AWG | 1.52 mm | 32.8 mm | 2,115 kg/km | 106 A |

*(Rated at 90°C conductor / 30°C ambient)*

Engineering Selection Guide

-

Voltage Compatibility: 2000V AC systems

-

Current Rating: 106A continuous load

-

Bending Radius: Minimum 6× cable diameter

-

Installation: Dynamic trailing/reeling applications

-

Safety Features: Dedicated ground-check circuit support

-

Environmental Suitability:

-

Underground mines (MSHA compliant)

-

Oil-exposed industrial sites

-

UV-exposed surface operations

-