UL THHN/THWN-2 Copper Wire | PVC/Nylon Insulated | 90°C Moisture & Flame Resistant | 600V Building Cable

Product Overview

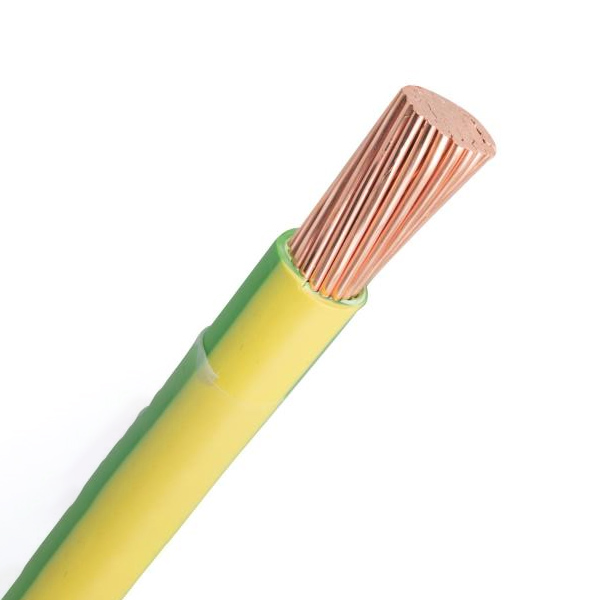

This UL-certified THHN/THWN-2 electrical cable delivers robust performance for commercial, industrial, and residential power distribution. Engineered with annealed copper conductors, flame-retardant PVC insulation, and abrasion-resistant nylon jacketing, it excels in heat/moisture resistance (90°C wet/dry) and flame propagation suppression. Compliant with UL 83 standards for 600V applications, it supports NEC-compliant installations in diverse environments.

Key Standards & Certifications

-

UL Standard: UL 83 (Thermoplastic Insulated Wires and Cables)

-

Listings: Dual-rated THHN/THWN-2

-

Voltage Rating: 600V

Construction

-

Conductor:

-

Annealed copper (solid: 14-10 AWG; stranded: 8 AWG-1000 kcmil)

-

Optimized conductivity and flexibility

-

-

Insulation:

-

Flame-retardant PVC (UL-recognized)

-

Resists heat, moisture, oils, and chemicals

-

-

Jacket:

-

Polyamide (Nylon) outer layer

-

Enhanced mechanical protection and conduit pullability

-

Temperature Ratings

| Rating | Dry/Damp Locations | Wet/Oil-Immersed |

|---|---|---|

| THHN/THWN | 90°C (194°F) | 75°C (167°F) |

| THWN-2 | 90°C (194°F) | 90°C (194°F) |

Applications

-

Service entrances, feeders, and branch circuits

-

Conduit, cable tray, and raceway installations

-

Industrial control systems & commercial machinery

-

NEC-compliant dry/damp/wet locations (THWN-2)

Technical Specifications

| Conductor Size (AWG/kcmil) | Stranding | Insulation Thickness (mils) | Jacket Thickness (mils) | Nominal O.D. (mils) | Approx. Weight per 1000 ft (lbs) | Allowable Ampacity (90°C) |

|---|---|---|---|---|---|---|

| 14 | 7 | 15 | 4 | 109 | 16 | 15 |

| 12 | 7 | 15 | 4 | 128 | 24 | 20 |

| 10 | 7 | 20 | 4 | 161 | 38 | 30 |

| 8 | 7 | 30 | 5 | 213 | 63 | 55 |

| 6 | 7 | 30 | 5 | 249 | 95 | 75 |

| 4 | 7 | 40 | 6 | 318 | 152 | 100 |

| 3 | 7 | 40 | 6 | 346 | 189 | 115 |

| 2 | 7 | 40 | 6 | 378 | 234 | 130 |

| 1 | 19 | 50 | 7 | 435 | 299 | 145 |

| 1/0 | 19 | 50 | 7 | 474 | 372 | 170 |

| 2/0 | 19 | 50 | 7 | 518 | 462 | 195 |

| 3/0 | 19 | 50 | 7 | 568 | 575 | 225 |

| 4/0 | 19 | 50 | 7 | 624 | 718 | 260 |

| 250 | 37 | 60 | 8 | 694 | 851 | 290 |

| 300 | 37 | 60 | 8 | 747 | 1012 | 320 |

| 350 | 37 | 60 | 8 | 797 | 1174 | 350 |

| 400 | 37 | 60 | 8 | 842 | 1334 | 380 |

| 500 | 37 | 60 | 8 | 926 | 1655 | 430 |

| 600 | 61 | 70 | 9 | 1024 | 1987 | 475 |

| 750 | 61 | 70 | 9 | 1126 | 2464 | 535 |

| 1000 | 61 | 70 | 9 | 1275 | 3257 | 615 |

(Note: Ampacities based on 90°C conductor temperature in free air (30°C ambient). Consult NEC for specific installation conditions and derating factors.)

Engineering Advantages

-

Safety Compliance: UL 83-certified flame retardancy

-

Environmental Resilience: 90°C wet/dry operation (THWN-2)

-

Durability: Nylon jacketing resists cuts, chemicals, and abrasion

-

Versatility: Dual rating for dry/damp/wet locations

-

Installation Efficiency: Smooth surface reduces conduit friction