Product Overview

YG UL3068/UL3069/UL3071/UL3074/UL3075/UL3122 Silicone Fiber Glass Braided Wire delivers extreme thermal resilience for demanding electrical applications. Featuring tinned copper conductors, dual-layer silicone insulation, and glass fiber braiding with silicone resin treatment, this wire operates reliably from -60°C to +200°C ambient (350°C surface temp). Certified to UL and GB standards, it provides superior resistance to acids, alkalis, oils, and fungal growth while maintaining stable electrical performance in high-heat environments.

Key Features

-

Temperature Range:

-

Ambient: -60°C to +200°C

-

Surface: Up to +350°C

-

-

Voltage Rating: 500V AC (300V/500V dual-rated)

-

Flame Resistance: Self-extinguishing per UL VW-1

-

Material System:

-

Conductor: Tinned copper (single/multistrand)

-

Insulation: Silicone rubber + glass fiber braid

-

Coating: External silicone resin treatment

-

-

Environmental Resistance: Acid/alkali/oil/UV/fungal/moisture proof

Cable Structure & Materials

| Layer | Material/Construction | Function & Properties |

|---|---|---|

| Conductor | Tinned copper | Single or multistrand (IEC 60228 Class 5/6) |

| Insulation | Silicone rubber | Thermal stability, elasticity retention |

| Reinforcement | Fiberglass braid | Mechanical protection, heat dissipation |

| Surface Treatment | Silicone resin coating | Waterproofing, chemical resistance, UV protection |

Technical Parameters

| Parameter | Value | Standard |

|---|---|---|

| Rated Voltage | 300V/500V AC | UL 3068-3122, GB/T 5013.3 |

| Conductor Size | 20 AWG to 10 AWG (0.5mm² - 6mm²) | UL 758 |

| Max. Conductor Temp | +200°C (continuous) | UL 758 |

| Spark Test Voltage | 5,000V (no breakdown) | GB5013.3-1997 |

| Dielectric Strength | 2,000V AC (1-min test) | IEC 60851 |

| Bending Radius | ≥6 × cable diameter | ISO 6722 |

Material Advantages

-

Silicone + Fiberglass System:

-

Maintains flexibility at -60°C; resists cracking at 350°C surface temps

-

Glass braid provides cut-through resistance and thermal dissipation

-

-

Tinned Copper Conductor:

-

Prevents oxidation at high temps, ensures stable conductivity

-

Stranded design allows 50% more flex cycles vs. solid core

-

-

Silicone Resin Coating:

-

Creates moisture/chemical barrier without compromising flexibility

-

Passes UL 1581 vertical flame test (VW-1)

-

Application Scenarios

-

High-Heat Industrial Equipment:

-

Ovens, industrial furnaces, foundry machinery, drying tunnels

-

-

Electrical Heating Systems:

-

Heating elements, infrared lamps, thermocouple wiring

-

-

Automotive & Transport:

-

Engine compartment wiring, ignition systems, EV battery heaters

-

-

Appliances & Lighting:

-

Commercial toasters, industrial microwaves, HID lighting fixtures

-

-

Harsh Environments:

-

Chemical plants, food processing machinery, marine equipment

-

Compliance & Standards

| Standard | Certification | Scope |

|---|---|---|

| UL | UL 3068, UL 3069, UL 3071 | Component recognition (US/Canada) |

| UL 3074, UL 3075, UL 3122 | ||

| International | GB/T 5013.3-2008 (IEC 60245-3) | 60245IEC03(YG) equivalent |

| Safety | VW-1 Flame Test | Vertical flame resistance |

| Performance | RoHS 3, REACH SVHC-free | Hazardous substance compliance |

Ordering Information

Base Models:

-

YG UL3068: Single conductor, 18-10 AWG

-

YG UL3069: Multistrand conductor, 20-10 AWG

-

YG UL3071/3074/3075/3122: Specialized variants (specify application)

Options:

-

Conductor: Tinned copper (default) or bare copper

-

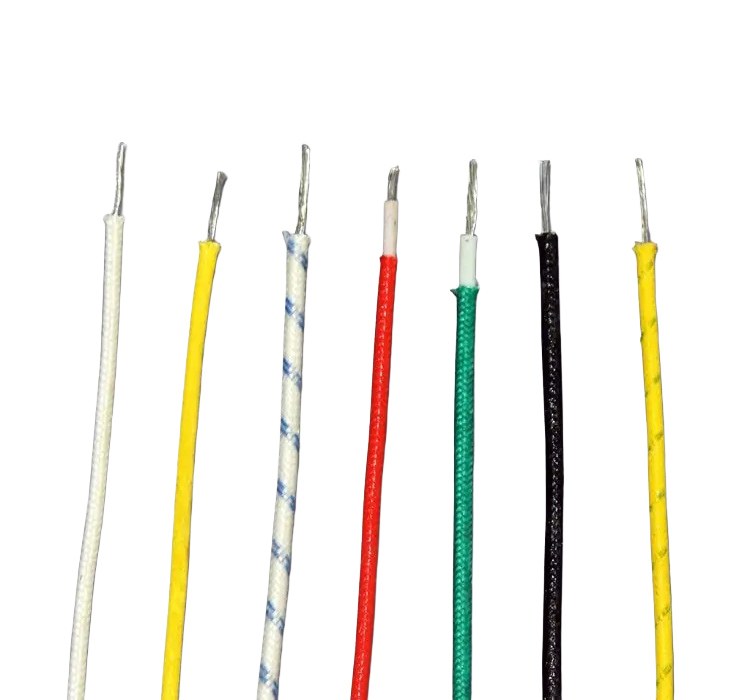

Colors: Red, black, yellow, green, blue, white, brown, gray, orange, yellow/green, transparent

-

Customization: Oil-resistant/UV-stabilized coatings, custom lengths

Engineering Tip: For radiant heat applications (>250°C surface temp), use transparent jacket to monitor conductor integrity.

Related Product Series

| Model | Temperature | Key Feature |

|---|---|---|

| UL3135 | +200°C | Higher current capacity |

| UL3123 | +150°C | PVDF jacket for chemical resistance |

| UL3195 | +125°C | Flexible automation wiring |

| 60245IEC03(YG) | +180°C | GB/IEC-compliant equivalent |