Product Overview

The AGG Series Silicone Rubber High Voltage Wire delivers exceptional performance in extreme DC applications up to 50kV. Engineered with imported high-pressure resistant silicone insulation and tinned copper conductors, this cable combines superior dielectric strength with unmatched flexibility. Ideal for high-temperature environments and critical electrical systems, it is available in customizable configurations from 3kV to 50kV, including multi-core designs.

Key Features & Benefits

| Property | Specification |

|---|---|

| Voltage Range | 3kV to 50kV DC (Customizable) |

| Temperature Range | -60°C to +200°C |

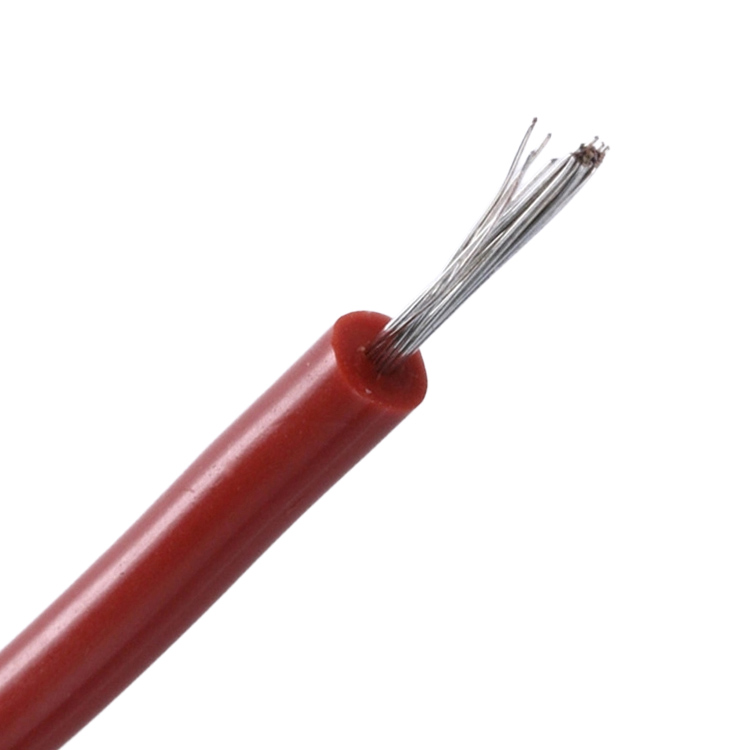

| Conductor | Stranded Tinned Copper (Enhanced Conductivity) |

| Insulation | Premium Silicone Rubber (Imported) |

| Key Advantages | High Voltage Resistance • Anti-Freezing • Lightweight • Extreme Flexibility |

| Color Options | Red, Yellow, Blue, White, Black, Green, etc. |

Technical Specifications

1. Electrical & Physical Properties

| Parameter | Value |

|---|---|

| Conductor Section | 0.1–10 mm² (AWG 24–10) |

| Insulation Thickness | 0.55–2.6 mm (Voltage-Dependent) |

| Dielectric Strength | Exceeds 60kV Peak |

| Chemical Resistance | Acids, Alkalis, Solvents, Ozone |

2. Voltage-Specific Insulation Thickness (Complete Table)

| AWG | Conductor Construction | 3kV | 6kV | 10kV | 20kV | 30kV | 40kV | 50kV | m/coil |

|---|---|---|---|---|---|---|---|---|---|

| 10 | 37×0.43 mm | 0.55 mm | 0.85 mm | 1.0 mm | 1.3 mm | 2.0 mm | 2.3 mm | 2.6 mm | 305 |

| 12 | 19×0.49 mm | 0.55 mm | 0.85 mm | 1.0 mm | 1.3 mm | 2.0 mm | 2.3 mm | 2.6 mm | 305 |

| 14 | 19×0.37 mm | 0.55 mm | 0.85 mm | 1.0 mm | 1.3 mm | 2.0 mm | 2.3 mm | 2.6 mm | 305 |

| 16 | 19×0.30 mm | 0.55 mm | 0.85 mm | 1.0 mm | 1.3 mm | 2.0 mm | 2.3 mm | 2.6 mm | 305 |

| 17 | 19×0.254 mm | 0.55 mm | 0.85 mm | 1.0 mm | 1.3 mm | 2.0 mm | 2.3 mm | 2.6 mm | 305 |

| 18 | 19×0.23 mm | 0.55 mm | 0.85 mm | 1.0 mm | 1.3 mm | 2.0 mm | 2.3 mm | 2.6 mm | 305 |

| 20 | 19×0.18 mm | 0.55 mm | 0.85 mm | 1.0 mm | 1.3 mm | 2.0 mm | 2.3 mm | 2.6 mm | 305 |

| 22 | 19×0.16 mm | 0.55 mm | 0.85 mm | 1.0 mm | 1.3 mm | 2.0 mm | 2.3 mm | 2.6 mm | 305 |

| 24 | 7×0.20 mm | 0.55 mm | 0.85 mm | 1.0 mm | 1.3 mm | 2.0 mm | 2.3 mm | 2.6 mm | 305 |

Standard coil length: 305 meters. Custom lengths available.

Construction & Materials

-

Conductor:

-

Multi-strand tinned copper wire (0.1–10 mm²) for optimal current carry and corrosion resistance.

-

-

Insulation:

-

High-purity silicone rubber providing:

-

Ultra-high dielectric strength (3–50kV DC)

-

Thermal stability across extreme temperatures

-

Resistance to cracking, moisture, and chemicals

-

-

-

Customization:

-

Voltage ratings: 3kV, 5kV, 10kV, 15kV, 20kV, 25kV, 30kV, 40kV, 50kV

-

Multi-core configurations available

-

Application Scenarios

-

High-Voltage Systems: Gas ignition, automotive spark systems, neon sign transformers.

-

Electronics: CRT displays, microwave oven magnetrons, TV receiver circuits.

-

Industrial: High-voltage test benches, diagnostic equipment, power supply units.

-

Instrumentation: Medical devices, aerospace sensors, laboratory measurement tools.

Engineering Selection Guide

| Requirement | Recommended Specification |

|---|---|

| DC Voltage | Select voltage rating 1.5× above operating voltage |

| Current Load | Choose conductor size (0.1–10 mm²) based on ampacity |

| Temperature | Suitable for continuous 200°C environments |

| Movement/Flexibility | Ideal for dynamic installations |

| Custom Needs | Multi-core, non-standard colors, or lengths |

Performance Advantages

-

Voltage Endurance: Withstands 60kV peak stress tests

-

Thermal Resilience: No degradation at -60°C to +200°C

-

Longevity: Resists aging, ozone, and environmental wear

-

Ease of Use: 30% lighter than PVC alternatives with superior bend radius