Product Overview

Multicore flexible halogen-free silicone cable SiHF/SiHF-C-Si delivers extreme temperature resilience (-60°C to +180°C) for harsh industrial environments. Certified to DIN VDE 0285-525-2-83/DIN EN 50525-2-83, this cable maintains electrical integrity and flexibility in high-heat, corrosive, and radiation-exposed applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Standards | DIN VDE 0250-1, DIN EN 50525-2-83 |

| Voltage Rating | 300/500V AC |

| Temp Range | -60°C to +180°C (Short-term: 220°C) |

| Conductor Temp Limit | +180°C continuous |

| Test Voltage | 2000V AC |

| Breakdown Voltage | ≥5000V |

| Insulation Resistance | ≥200 MΩ·km |

| Bending Radius | Fixed: 4×Ø · Flexing: 7.5×Ø |

| Radiation Resistance | 20 Mrad (20×10⁶ cJ/kg) |

| Flame Propagation | Self-extinguishing (IEC 60332-1-2) |

| Halogen Content | Free (IEC 60754-2 compliant) |

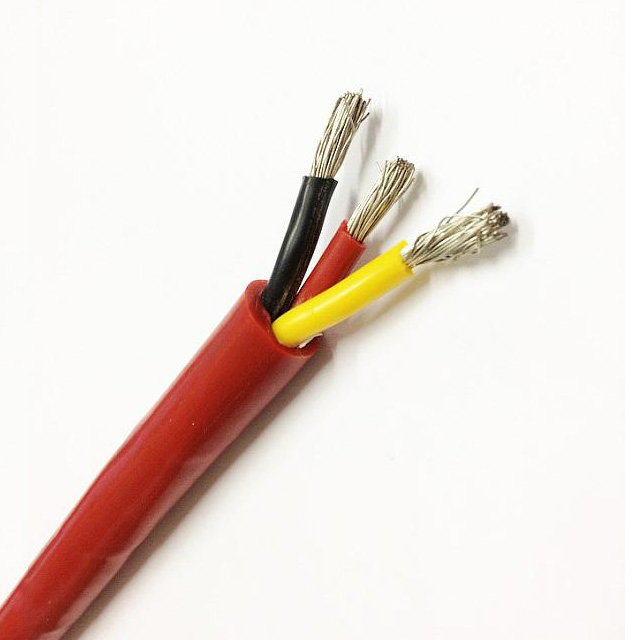

Construction Details

1. Conductor

-

Material: Tinned copper (99.99% electrolytic)

-

Class: DIN VDE 0295 Cl.5 / IEC 60228 Cl.5 (fine-stranded)

-

Flexibility: Optimized lay length for repeated bending

2. Insulation

-

Material: Silicone rubber

-

Thickness: DIN VDE 0285 compliant

-

Core Identification:

-

≤5 cores: Color-coded

-

≥6 cores: Black with white numbering

-

Ground: Green-Yellow (GN-YE)

-

3. Sheath

-

Material: Halogen-free silicone rubber

-

Color: Red-brown (standard) with meter marking

-

Protection: Forms SiO₂ insulating layer during fire

Material Properties

| Component | Key Characteristics | Test Standard |

|---|---|---|

| Silicone | Dielectric stability @180°C | DIN VDE 0285 |

| Tinned Copper | Corrosion resistance ≥98% IACS | IEC 60228 Cl.5 |

| Sheath | Auto-extinguishing, halogen-free | IEC 60754-2 / DIN EN 50267-2-2 |

Key Performance Advantages

-

Thermal Stability: Maintains flexibility from -60°C to +180°C

-

Fire Safety: Zero halogen emission, forms insulating SiO₂ ash

-

Chemical Resistance: Withstands oils, alcohols, diluted acids/alkalis (pH 1-14)

-

Radiation Hardened: Stable up to 20 Mrad (nuclear/medical applications)

-

Power Derating Table:

Temp (°C) 150 155 160 165 170 175 Load % 100 91 82 71 58 41

Application Scenarios

High-Temperature Industrial

-

Steel mill furnace wiring

-

Glass manufacturing equipment

Critical Infrastructure

-

Nuclear power plant control systems

-

Petrochemical reactor instrumentation

Harsh Environments

-

Food processing sterilization zones

-

Pharmaceutical autoclave connections

Mobile Equipment

-

Welding machinery cables

-

Foundry crane electrification

Engineering Selection Guide

| Factor | Calculation Method | Critical Values |

|---|---|---|

| Current Rating | DIN VDE 0100 (145°C base) | Derate per temp table above |

| Voltage Drop | ΔU = (I × L × √3)/(κ × S × cosφ) | Max 5% @ 180°C |

| Bending Stress | DIN VDE 0482-332-1-2 | >50,000 cycles @ 7.5×Ø |

| Installation | Critical Restriction: Fixed installs require ventilated conduits/ducts above 90°C |

Compliance & Certifications

-

Primary Standards:

-

DIN VDE 0285-525-2-83

-

DIN EN 50525-2-83

-

IEC 60228 Cl.5

-

-

Fire Safety:

-

IEC 60332-1-2 (Flame retardancy)

-

IEC 60754-2 (Halogen-free)

-

-

Environmental: RoHS 3 / REACH

Certification Marks: VDE ● TÜV ● CE ● UKCA

Critical Installation Notes

⚠️ Mandatory Requirements

-

Fixed installations MUST use ventilated conduits/ducts where ambient >90°C

-

Avoid tight bends: Minimum 7.5× cable diameter for dynamic applications

-

Use silicone-compatible cable glands for IP protection

AWG sizes are approximate equivalents - always select by mm² cross-section