Product Overview

The H07RN-F 5G2.5mm² is a harmonized heavy-duty rubber cable engineered for three-phase industrial applications in extreme conditions. Certified to EN 50525-2-21 (HD 22.12 S2) and IEC 60245-4, this 5-core flexible cable delivers superior mechanical protection, oil/weather resistance, and flexibility for mobile three-phase equipment. With -25°C to +60°C operating range and 450/750V rating, it powers critical machinery in harsh environments.

Key Technical Specifications

| Parameter | Specification | Standard |

|---|---|---|

| H-Code | H07RN-F | HD 361 S3 |

| Rated Voltage | 450/750V (U₀/U) | EN 50525-2-21 |

| Conductor | Plain Copper (Cu), Class 5 stranded | IEC 60228, Class 5 |

| Core Configuration | 5 cores × 2.5mm² (3Ph+N+PE) | HD 22.12 S2 |

| Insulation | EPR Rubber (Ethylene Propylene) | EN 50363-5 |

| Sheath | Chloroprene Rubber (CR) | EN 50363-7 |

| Temperature | Operating: -25°C to +60°C Short Circuit: +250°C |

EN 50525-1 |

| Bending Radius | Min. 6 × Cable Diameter | IEC 60245-2 |

| Flame Retardancy | IEC 60332-1-2 (Vertical flame test) | IEC 60332-1-2 |

| Conductor Resistance | ≤ 7.41 Ω/km @ 20°C (per core) | IEC 60245-4 |

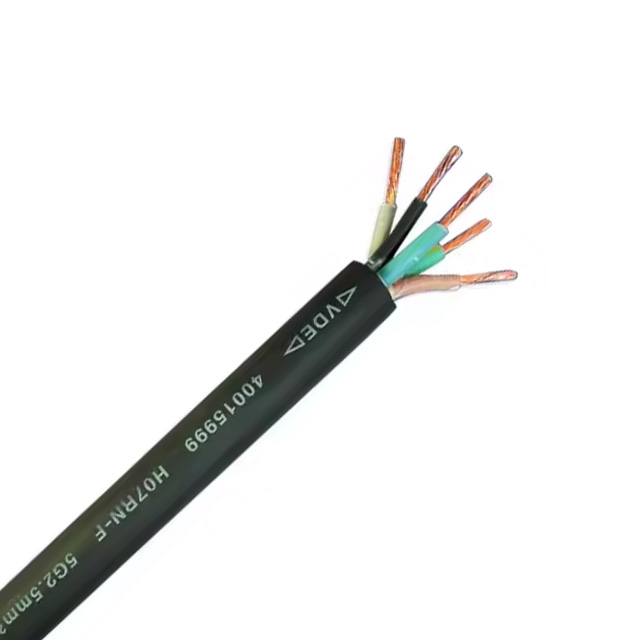

Construction & Materials

-

Conductor:

-

5 × 2.5mm² bare copper conductors (IEC 60228 Class 5)

-

Highly stranded for flexibility (56 wires @ 0.26mm typical)

-

-

Insulation:

-

Individual EPR rubber insulation per core

-

Color-coded: Brown/Black/Grey (Phases), Blue (Neutral), Green/Yellow (Earth)

-

Nominal thickness: 0.9mm

-

-

Assembly:

-

Cores laid parallel with circular formation

-

-

Sheath:

-

Black chloroprene rubber (CR) outer jacket

-

Nominal thickness: 1.6mm

-

Longitudinal ribbing for identification

-

Material Advantages

| Property | Technical Benefit |

|---|---|

| Sub-Zero Flexibility | Maintains pliability at -25°C (IEC 60811-1-4) |

| Oil/IP56 Resistance | Withstands oils/IP56 water ingress |

| Abrasion Resistance | 200% better than PVC (EN 50396 scrape test) |

| UV/Ozone Stability | 1,000+ hrs resistance (EN 50396) |

| Flame Performance | Self-extinguishing (IEC 60332-1-2) |

Applications

Designed for three-phase portable equipment:

-

Construction site distribution boards

-

Mobile generators & welding rigs

-

Industrial pumps & compressors

-

Quarry/Mining conveyor systems

-

Shipyard shore power connections

-

Agricultural processing machinery

Engineering Selection Guide

| Parameter | Requirement |

|---|---|

| Voltage System | 400V 3Ph+N+PE (50Hz) |

| Current Capacity | 25A @ +60°C ambient (IEC 60287) |

| Bending Radius | Min. 90mm (OD≈15mm) |

| Installation | Portable use ONLY - not for fixed wiring |

| Certification Marks | H07RN-F 5G2.5 ▼0274 on sheath |

| CPR Classification | Euroclass Dca-s1b,d1,a1 |

Dimensional Data

| Parameter | Value | Tolerance |

|---|---|---|

| Nominal OD | 15.2 mm | ±0.4 mm |

| Conductor Diameter | 1.84 mm | ±0.03 mm |

| Insulation Thickness | 0.9 mm | +0.1 mm |

| Sheath Thickness | 1.6 mm | +0.2 mm |

| Weight | 340 kg/km | ±5% |

Standards Compliance

| Standard | Requirement |

|---|---|

| Harmonized | HD 22.12 S2 |

| Insulation | EN 50363-5 (EPR) |

| Sheath | EN 50363-7 (CR) |

| Flame Test | IEC 60332-1-2 |

| Environmental | RoHS 3, REACH SVHC-free |

| Safety | CE Marked, CPR Certified |

Critical Notices:

✖️ Not for permanent installation or direct burial

✔️ Mandatory use of IP68 cable glands

⚠️ Annual insulation resistance test: ≥100 MΩ/km @ 500V DC