Product Overview

The H07RN-F 3G1.5mm² is a premium harmonized rubber cable designed for extreme industrial environments. Certified to EN 50525-2-21 (HD 22.12 S2) and IEC 60245, this heavy-duty flexible cable delivers superior mechanical protection, weather resistance, and flexibility for mobile equipment in demanding applications. With a temperature range of -25°C to +60°C and 450/750V rating, it's the optimal solution for portable power supply in harsh conditions.

Key Technical Specifications

| Parameter | Specification | Standard Reference |

|---|---|---|

| H-Code | H07RN-F | HD 361 S3 |

| Rated Voltage | 300/500V (U₀/U) | EN 50525-2-21 |

| Test Voltage | 2,000V AC (5 min) | IEC 60245-2 |

| Conductor | Material: Plain Copper (Cu) Class: 5 (Fine-wire stranded) Cross-section: 3 x 1.5mm² |

IEC 60228, Class 5 |

| Insulation | Material: EPR (Ethylene Propylene Rubber) Thickness: 0.8mm min Colors: Brown (L1), Blue (N), Green/Yellow (PE) |

EN 50363-5 |

| Sheath | Material: CR (Chloroprene Rubber) Thickness: 1.5mm min Color: Black |

EN 50363-7 |

| Temperature | Operating: -25°C to +60°C Max Conductor Temp (short circuit): +250°C |

EN 50525-1 |

| Bending Radius | Min. 6 x Cable Diameter | IEC 60245-2 |

| Flame Retardancy | IEC 60332-1-2 (Single vertical flame test) | IEC 60332-1-2 |

| Standards | Harmonized: HD 22.12 S2 EN: EN 50525-2-21 IEC: IEC 60245-4 |

HD 22.12, EN 50525-2-21 |

Conductor Resistance (max @ 20°C): 13.3 Ω/km (per core)

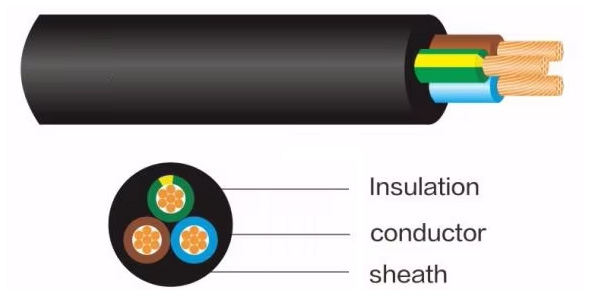

Construction Details

-

Conductor:

-

Highly flexible stranded copper (Class 5)

-

Cross-section: 1.5mm² per core (3 cores)

-

Conforms to IEC 60228 Class 5 flexibility requirements

-

-

Insulation:

-

EPR rubber compound for each core

-

Color-coded per harmonized standards (Brown/Blue/G-Y)

-

Excellent heat and aging resistance

-

-

Assembly:

-

Cores laid parallel without filler

-

-

Sheath:

-

Heavy-duty chloroprene rubber (CR) outer jacket

-

Resistant to oils, chemicals, abrasion, and weathering

-

Nominal thickness: 1.5mm

-

Black color with surface ribbing for identification

-

Material Advantages

-

Extreme Flexibility: Maintains pliability in sub-zero temperatures (-25°C)

-

Weather/Oil Resistant: CR sheath withstands UV, ozone, and mineral oils

-

Abrasion Protection: 50% thicker sheath than standard PVC cables

-

Flame Retardant: Self-extinguishing per IEC 60332-1-2

-

High Temperature Resilience: EPR insulation withstands temporary overloads

-

Water Resistance: IP66 equivalent protection when properly terminated

-

Certified Safety: CE marked, compliant with CPR Euroclass Dca-s1b,d1,a1

Application Scenarios

Ideal for portable equipment in harsh environments:

-

Construction site distribution systems

-

Welding equipment and portable generators

-

Agricultural machinery and irrigation systems

-

Industrial tools and mobile workshop equipment

-

Stage lighting and entertainment systems

-

Shipyard and marine applications

-

Mining equipment and quarry operations

Engineering Selection Notes:

-

Voltage Rating: Suitable for 450/750V systems (max 500V phase-phase)

-

Temperature: Avoid continuous use >60°C ambient temperature

-

Bending Radius: Minimum 6×OD during installation (approx. 45mm for 3G1.5)

-

Installation:

-

Never install as fixed wiring

-

Use cable glands with compression seals

-

Avoid sharp edges and dynamic abrasion points

-

-

Certification: Valid only when bearing H07RN-F 3G1.5 and ▼0274 markings

Dimensional Data

| Parameter | Value | Tolerance |

|---|---|---|

| Nominal OD | 12.0 mm | ±0.3 mm |

| Conductor Diameter | 1.45 mm | ±0.02 mm |

| Insulation Thickness | 0.8 mm | +0.1 mm |

| Sheath Thickness | 1.5 mm | +0.2 mm |

| Weight | 195 kg/km | ±5% |

Compliance & Certification

-

EU Harmonized: HD 22.12 S2

-

International: IEC 60245-4

-

Flame Test: IEC 60332-1-2

-

Environmental: RoHS 3, REACH SVHC

-

CPR Classification: Euroclass Dca-s1b,d1,a1

Warning: Not suitable for fixed installations or direct burial. Always use with appropriate strain relief devices. Test annually for insulation resistance (>100 MΩ/km).