Product Overview

The H07RN-F is a premium heavy-duty flexible rubber cable engineered for demanding environments requiring exceptional resilience against mechanical stress, oils, weathering, and extreme conditions. Its robust construction delivers reliable power transmission for industrial, construction, agricultural, and temporary applications where standard cables fail.

Key Features

| Property | Performance |

|---|---|

| Flexibility | Class 5 stranded copper for continuous flexing |

| Temperature Range | -25°C to +70°C (ambient & conductor) |

| Environmental Resistance | Oils, UV, ozone, weathering, hydrolysis |

| Mechanical Protection | Superior abrasion/cut/tear/crush resistance |

| Flame Performance | Self-extinguishing (IEC 60332-1-2) |

| Chemical Resistance | Chloroprene sheath protects against moisture and chemicals |

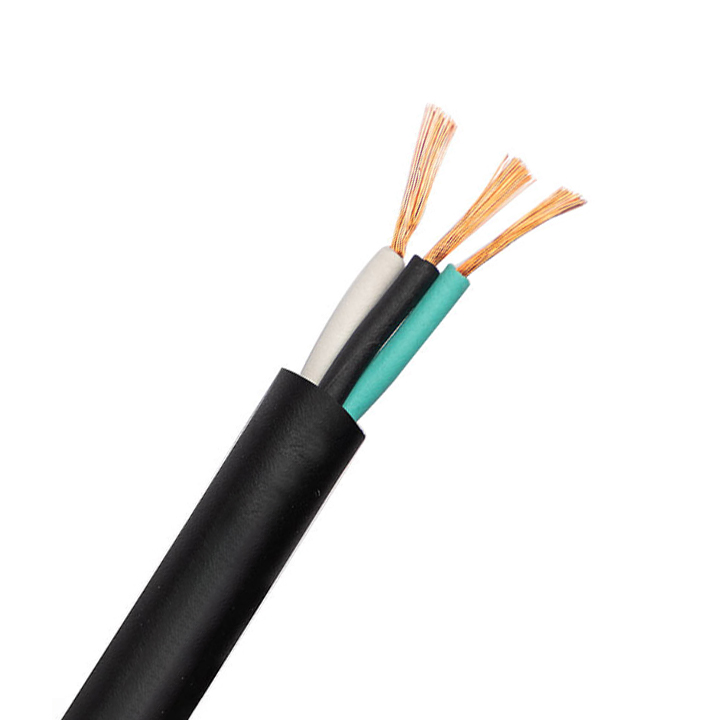

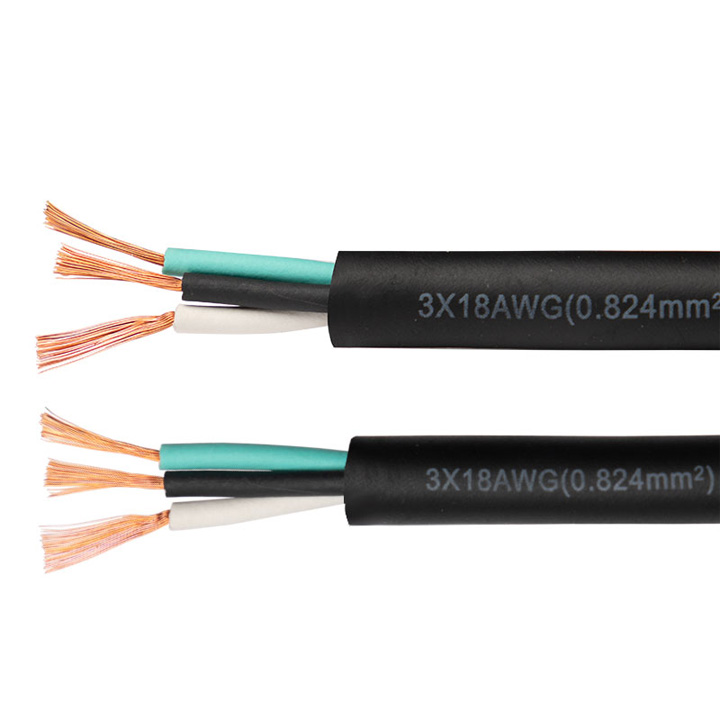

Construction Details

1. Conductor

-

Material: Bare copper or tinned copper

-

Standard: IEC 60228 Class 5

-

Sizes: 1.5mm² to 630mm² (multi-core) / 1000mm² (single-core)

-

Identification: Color-coded per HD 308 (Brown, Blue, Black, Grey + G/Y Earth)

2. Insulation

-

Material: EPR (Ethylene Propylene Rubber)

-

Standard: IEC 60245-4 Type EI4

-

Function: Electrical isolation and thermal stability

3. Sheath

-

Material: Chloroprene Rubber (CR)

-

Standard: IEC 60245-4 Type SE3

-

Color: Standard black (custom colors available)

-

Thickness: Complies with IEC 60245-4 minimum values

Technical Specifications

| Parameter | Value | Standard |

|---|---|---|

| Rated Voltage | 450/750 V | IEC 60245-4 |

| Test Voltage | 2500V AC | IEC 60245-4 |

| Min. Bending Radius | 6 × Cable Ø | IEC 60245-4 |

| Insulation Resistance | >10 MΩ·km | IEC 60245-4 |

| Operating Temperature | -25°C to +70°C | IEC 60245-4 |

Product Advantages

1. Certified Reliability

-

Full compliance with HD 22.14 and IEC 60245-4 standards

-

Third-party verified flame retardancy (IEC 60332-1-2)

-

RoHS 3 (2011/65/EU) environmental compliance

2. Engineered Durability

-

CR sheath provides industry-leading resistance to:

-

Oils, greases, and industrial chemicals

-

UV radiation and ozone degradation

-

Abrasion and mechanical impact

-

-

Maintains flexibility at extreme temperatures (-25°C to +70°C)

3. Operational Efficiency

-

Class 5 conductors withstand >50,000 flex cycles

-

Reduced downtime through extended service life

-

Lower total cost of ownership vs. standard cables

4. Application Versatility

Validated performance in critical sectors:

-

Construction sites and portable generators

-

Agricultural machinery and outdoor installations

-

Mining equipment and industrial conveyors

-

Event power systems and marine shore connections

Typical Applications

-

Mobile industrial equipment (welding machines, CNC tools)

-

Temporary site power distribution

-

Agricultural machinery (tractors, irrigation systems)

-

Port equipment (cranes, winches)

-

Event power systems (festivals, exhibitions)

-

Mining and quarrying operations

Engineering Selection Guidelines

-

Current Capacity: Calculate using IEC 60364-5-52

-

Voltage Drop: Limit to ≤3% for power circuits

-

Bending Radius: Maintain minimum 6× cable diameter

-

Environmental Limits:

-

Avoid continuous exposure >70°C

-

Not for permanent burial

-

Verify chemical compatibility for harsh solvents

-

-

Installation Warning:

Not approved for fixed building wiring. Use only in:-

Flexible connections with strain relief

-

Cable trays/conduits with mechanical protection

-

Temporary installations per IEC 60364-7-704

-

Compliance & Standards

Manufactured to international harmonized standards:

-

HD 22.14 S1 (EU Directive)

-

IEC 60245-4 (International)

-

RoHS 3 (2011/65/EU)

-

Flame Propagation: IEC 60332-1-2 Certified