Product Description

Durable and Reliable Construction

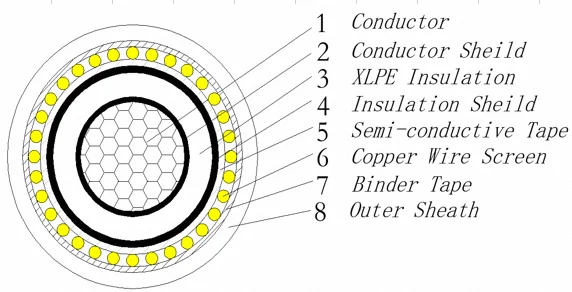

This power cable features a steel tape armor and XLPE insulation, ensuring long-lasting and reliable performance in various industrial applications, including those in challenging environments.

High-Temperature Resistance

The PVC sheath provides excellent UV resistance, making it suitable for use in extreme temperatures and outdoor installations.

Note: Ensure clarity regarding the temperature resistance provided by the material used.

Fire-Resistant and Flame Retardant

This cable meets special requirements for fire-resistant and flame retardant properties, ensuring a safe working environment and reducing the risk of fire hazards.

Low Smoke Emission

The cable is designed to emit minimal smoke in the event of a fire, reducing the risk of asphyxiation and allowing for a safe evacuation of the premises.

Versatile and Customizable

Available in a range of sizes (1x25-3x630) and suitable for both low and medium voltage applications, this cable can be used in various industrial settings, including those requiring specific user input for customized solutions.

Key Attributes

| Attribute | Details |

|---|---|

| Insulation Material | XLPE |

| Application | Industrial |

| Conductor Material | Copper, Aluminum |

| Jacket | PVC, PE, LSZH |

| Model Number | YJV, YJLV, YJV32, YJLV32, etc. |

| Type | Medium Voltage / Low Voltage |

| Size | 1x25 - 3x630 |

| Rated Voltage | 3.6 - 33kV |

| Packing | Wooden Drum / Iron Drum |

| Feature | UV Resistance |

| Special Requirements | Fire-resistant, Flame retardant, Low smoke |

| Sectional Area | 25sqmm - 630sqmm |

| Products Description | XLPE insulated power cable for rated voltage 26/35KV |

Cable Technical Parameters

D.C Resistance of Conductor and Maximum Short Circuit Current

| Nominal Cross-sectional Area (mm²) | Max. D.C Resistance of Conductor at 20°C (Ω/km) | Max. Allowable Short-circuit Current of Conductor at 90°C (1 second) |

|---|---|---|

| Copper Conductor | Aluminum Conductor | Copper Conductor |

| 25 | 0.727 | 1.2 |

| 35 | 0.524 | 0.868 |

| 50 | 0.387 | 0.641 |

| 70 | 0.268 | 0.443 |

| 95 | 0.193 | 0.32 |

| 120 | 0.153 | 0.253 |

| 150 | 0.124 | 0.206 |

| 185 | 0.0991 | 0.164 |

| 240 | 0.0754 | 0.125 |

| 300 | 0.0601 | 0.1 |

| 400 | 0.047 | 0.0778 |

| 500 | 0.0366 | 0.0605 |

| 630 | 0.0283 | 0.0469 |