Product Overview

The 600V/1kV MC-HL Armored Power Cable with Flame-Retardant Cross-Linked Polyethylene (FR-XLP/XHHW-2) insulation is engineered for demanding industrial and hazardous environments. Featuring a continuously welded corrugated aluminum armor and UV-resistant jacket, this cable provides superior moisture protection, EMI shielding, and mechanical durability. Compliant with NEC, UL, and ICEA standards, it is ideal for power distribution, variable frequency drive (VFD) systems, and installations requiring flame resistance, direct burial, or exposure to harsh conditions.

Key Features:

-

Voltage Rating: 600V/1kV.

-

Temperature Ratings: 90°C (continuous), 130°C (emergency), 250°C (short circuit).

-

Hazardous Locations: NEC Class I/II/III Div 1/2 (Articles 501-503).

-

Construction: 3 symmetrically placed ground wires for VFD/PWM compatibility.

-

Certifications: UL 1569 (MC-HL), UL 44, ICEA S-95-658, IEEE 1202 flame retardant.

Technical Specifications

| Parameter | Description |

|---|---|

| Conductor | Soft annealed copper (ASTM B3), compact round stranding (ASTM B496). |

| Insulation | FR-XLP (XHHW-2), flame-retardant, ozone-resistant, UL 44 compliant. |

| Grounding | 3 symmetrically placed bare copper grounds (3-conductor cables); meets UL/NEC. |

| Armor | Continuously welded corrugated aluminum, moisture-impervious, NEC 250 compliant. |

| Jacket | Sunlight-resistant PVC or Low-Smoke Halogen-Free (LSHF) polyolefin. |

| Voltage Rating | 600V/1kV. |

| Installation | Direct burial, concrete embedding, cable trays, aerial, wet/dry locations. |

| Flame Tests | IEEE 1202 (70k BTU), ICEA T-29-520 (210k BTU). |

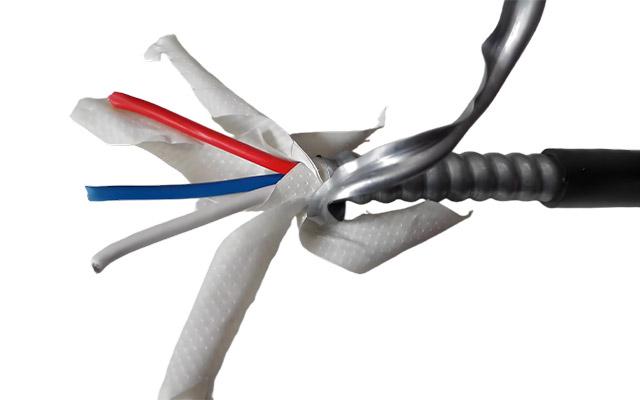

Construction Details

-

Conductor:

-

Copper: Soft annealed, compact-stranded for flexibility and conductivity (ASTM B3/B496).

-

-

Insulation:

-

FR-XLP (XHHW-2): Flame-retardant cross-linked polyethylene with high dielectric strength and thermal stability.

-

Phase identification via numbered coding for easy installation.

-

-

Grounding System:

-

3-Conductor Cables: Three symmetrically placed bare copper grounds for VFD noise mitigation.

-

Single/Multi-Conductor: Helical or interstitial grounding per UL/NEC requirements.

-

-

Armor & Jacket:

-

Aluminum Armor: Continuously welded, corrugated design blocks moisture and provides crush resistance.

-

Jacket Options:

-

PVC: UV/ozone-resistant, cost-effective.

-

LSHF Polyolefin: Low smoke, halogen-free for enhanced safety in confined spaces.

-

-

Applications

-

Hazardous Locations: Oil refineries, chemical plants (NEC Class I/II/III Div 1/2).

-

Industrial Automation: VFD/PWM motor control, PLC systems, machinery power feeds.

-

Infrastructure: Direct burial, concrete-embedded, cable trays, aerial messenger lines.

-

Commercial Buildings: Emergency power circuits, HVAC systems, lighting.

Compliance & Certifications

-

Standards: UL 1569 (MC-HL), UL 44, ICEA S-95-658/NEMA WC70, IEEE 1202.

-

Flame Resistance: Passes ICEA T-29-520 (210k BTU) and IEEE 1202 (70k BTU).

-

Environmental Ratings: Sunlight-resistant, direct burial, and CT (cable tray) use.

Engineering Advantages

-

Safety: Flame-retardant insulation and LSHF jacket minimize fire risks and toxic emissions.

-

Durability: Aluminum armor protects against moisture, chemicals, and mechanical stress.

-

EMI Shielding: Continuous welded armor reduces electromagnetic interference in VFD applications.

-

Flexibility: Compact stranding and lightweight design simplify routing in tight spaces.

Ordering Information

Specify:

-

Conductor size and quantity.

-

Jacket type (PVC or LSHF).

-

Grounding configuration (symmetrical/interstitial).