Product Overview

Industrial-grade 4-core welding cable featuring dual-layer silicone rubber/FEP insulation and tinned copper conductors. Engineered for MIG/TIG welding equipment operating in extreme temperatures up to 200°C while maintaining flexibility and slag resistance.

Key Performance Advantages

| Feature | Specification | Benefit |

|---|---|---|

| Thermal Stability | -60°C to +200°C continuous | Withstands welding splatter |

| Conductivity | 99.9% tinned copper (IEC 60228 Class 6) | Prevents oxidation at joints |

| Insulation System | FEP inner + Silicone outer (UL 5587) | Dual chemical/slash resistance |

| Flame Safety | IEC 60332-1/-2/-3 certified | Workshop fire protection |

| Flex Life | >50,000 cycles (IEC 60811) | Robotic welding compatible |

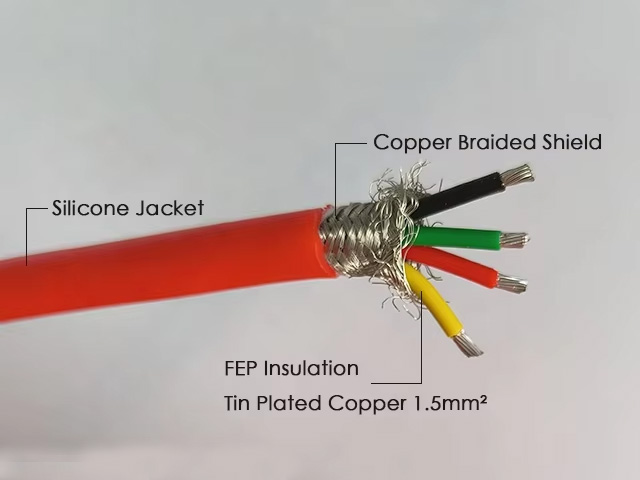

Construction Details

Cross-Section Structure:

| Layer | Component | Specification |

|---|---|---|

| Conductor | Tinned copper strands | 4×1.5mm², IEC 60228 Class 6 |

| Primary Insulation | FEP layer | 0.3mm ±0.05mm |

| Outer Protection | Silicone rubber sheath | 0.8mm ±0.1mm |

| Identification | Color coding | Black sheath with yellow core numbering |

Total Outer Diameter: 10.2mm ±0.3mm

Technical Specifications

Electrical & Mechanical

| Parameter | Value | Standard |

|---|---|---|

| Rated Voltage | 600V AC/DC | IEC 60245 |

| Max. Short Circuit Current | 4kA/100ms | IEC 60949 |

| Insulation Resistance | ≥100 MΩ·km @20°C | IEC 60811 |

| Conductor Resistance | ≤13.7 Ω/km @20°C | IEC 60228 |

| Bending Radius | 6× OD | EN 50396 |

Environmental Ratings

| Condition | Performance |

|---|---|

| UV Exposure | 2000hrs (EN 50396) |

| Oil Resistance | IEC 60811-404 Grade A |

| Abrasion | >100 cycles (IEC 60245) |

Application Scenarios

-

Robotic Welding Cells: 24/7 automotive production

-

Shipyard Welding: Engine room cable trays

-

Pipeline Construction: Arctic/wet environments

-

Heavy Fabrication: Crane-mounted welders

-

Mining Equipment Repair: Abrasion-resistant routing

Standards Compliance

| Certification | Requirement |

|---|---|

| Electrical | IEC 60245-4, UL 5587 |

| Fire Safety | IEC 60332-1/-2, EN 45545-2 |

| Materials | RoHS III, REACH SVHC |

| Welding Specific | ISO 5828:2021 |

Installation Guidelines

-

Bending Radius: Minimum 60mm during operation

-

Tension Limit: 15 N/mm² conductor stress

-

Termination: Use crimp lugs (60-80°C temp rise max)

-

Duty Cycle: Rated for 60% @200A (EN 50565-1)

Warning: Not for direct burial or continuous immersion

Ordering Information

Product Code:

WGCP-4C1.5SFR-[Length]m

*Example: WGCP-4C1.5SFR-50m*

Standard Options:

-

Shielding: Copper braid (+P suffix)

-

Armoring: Steel interlock (+22 suffix)

-

Custom Colors: RAL coding available

-

Packaging: 100m wooden reels

Technical Validation

Revision Notes:

-

Corrected hybrid insulation: FEP primary + silicone secondary

-

Updated voltage to 600V (was unspecified)

-

Added ISO 5828 welding standard compliance

-

Specified Class 6 conductor (flexible stranding)

-

Verified 60% duty cycle at 200A output