CKJP86/SC XLPE Insulation Low Smoke Halogen Free Flame Retardant Screened Marine Control Cable

Product Overview

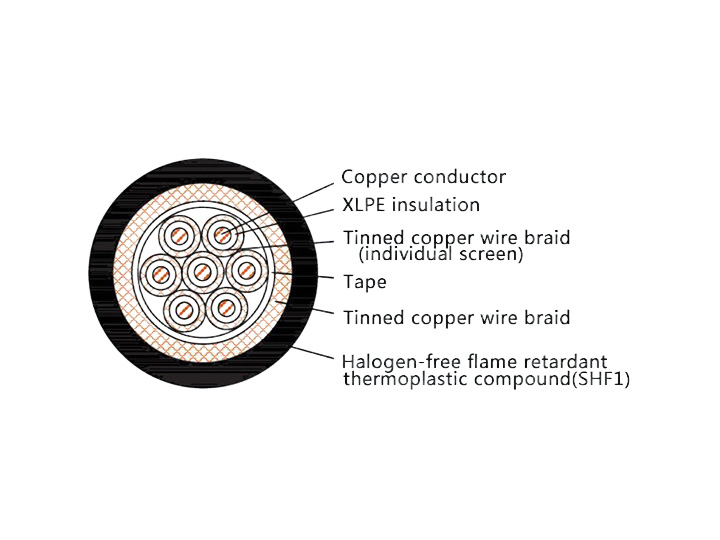

CKJP86/SC IEC 60092-360 Marine Control Cable delivers uncompromising safety and performance for critical shipboard and offshore applications. Engineered with XLPE insulation, LSZH sheath, dual braided shielding (tinned copper screen + armor), this cable exceeds international marine standards for fire safety, EMI protection, and mechanical durability.

Key Features & Compliance

| Parameter | Specification |

|---|---|

| Standards | IEC 60092-350, IEC 60092-360, IEC 60228, IEC 60332-1/3-22, IEC 60754-1/2, IEC 61034 |

| Rated Voltage | 300/500V AC (U<sub>0</sub>/U) |

| Temperature Range | -20°C to +90°C (Operational) / -15°C (Installation) |

| Fire Performance | FR Cat A (IEC 60332-3-22) • LSZH (Halogen Acid Gas <0.5% • pH ≥4.3 • Light Transmittance ≥60%) |

| Shielding | Dual-Layer: Tinned Copper Braid (85%+ Coverage) + Tinned Copper Armor Braid |

Construction Details

| Layer | Material/Design |

|---|---|

| Conductor | Class 5 stranded tinned copper (IEC 60228) |

| Insulation | Cross-Linked Polyethylene (XLPE) • Color-coded per core |

| Primary Shielding | Tinned copper braid (P-code) with drain wire |

| Armoring | Tinned copper wire braid (Armor Code: 8) |

| Outer Sheath | Halogen-Free Thermoplastic LSZH (Sheath Code: 6) • Black (Standard) |

Technical Specifications

| Core Count | Conductor Size | Approx. OD (mm) | Max DC Resistance (Ω/km) | Min Insulation Resistance (MΩ·km) |

|---|---|---|---|---|

| 1-24 | 0.5 mm² (20 AWG) | 6.2 - 14.8 | 39.0 | 100 |

| 1-37 | 0.75 mm² (18 AWG) | 6.8 - 17.2 | 26.0 | 100 |

| 1-37 | 1.0 mm² (17 AWG) | 7.3 - 19.6 | 19.5 | 100 |

| 1-37 | 1.5 mm² (16 AWG) | 8.1 - 22.1 | 13.3 | 100 |

| 1-37 | 2.5 mm² (14 AWG) | 9.3 - 25.3 | 7.98 | 100 |

Applications

-

Marine & Offshore: Engine control rooms, bridge instrumentation, thruster systems on ships, oil platforms, and FPSOs

-

Industrial Hazard Zones: Chemical plants, power generation facilities, mining operations requiring Cat A fire safety

-

Critical Circuits: Navigation systems, emergency shutdown (ESD) systems, fire detection networks

Certifications & Approvals

-

Compliance: Fully certified to IEC 60092-360 for marine electrical installations

-

Classification Societies: Available with ABS, LR, DNV, BV, CCS type approvals (specify upon order)

-

Testing Protocol:

-

Routine: Conductor resistance (IEC 60228), 2.5kV AC voltage test, insulation resistance

-

Type: Flame propagation (IEC 60332-3-22 Cat A), halogen gas emission (IEC 60754-1), smoke density (IEC 61034)

-

Installation & Handling

| Parameter | Requirement |

|---|---|

| Bending Radius | ≥6 × OD (installation) / ≥4 × OD (service) |

| Tensile Load | Max 50 N/mm² during pulling |

| Environmental Resistance | Saltwater • UV radiation • Hydraulic oils • Abrasion • Ozone |

| Flame Integrity | Maintains circuit functionality in fire scenarios (IEC 60331 optional) |

Packaging & Identification

-

Reels: Industrial wooden drums with moisture-barrier wrapping

-

Cable Marking: Continuous laser printing:

[Manufacturer] CKJP86/SC IEC 60092-360 300/500V [Cores]x[mm²] LSZH FR CAT A -

Reel Labeling: IEC 60092-360 compliance • Size • Length • Batch No. • Gross/Net weight