Product Overview

The CEPFR96/SC is a premium-grade, halogen-free, low-smoke, flame-retardant marine flexible power cable engineered for the most critical and demanding applications. It combines superior Ethylene Propylene Rubber (EPR) insulation for electrical integrity, a complete thermoplastic polyolefin (SHF1) dual-sheath system, and galvanized steel wire braid armor. This construction offers an uncompromising solution, delivering exceptional electrical performance, maximum mechanical and environmental protection, and enhanced fire safety for vital circuits in harsh marine and industrial environments.

Technical Specifications

-

Rated Voltage (U₀/U): 0.6/1 kV

-

Maximum Continuous Conductor Temperature: 90°C

-

Conductor: Tinned or Plain Stranded, Annealed Copper Wire (Class 5/6 flexible) (IEC 60228)

-

Available Cross-Sections: 0.75 mm² to 300 mm²

-

Core Configurations: 1 to 37 Cores

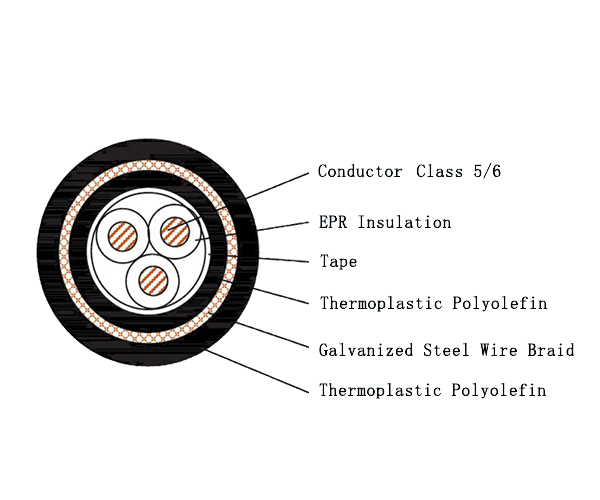

Cable Construction & Materials

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned/Plain Stranded, Annealed Copper Wire (Flexible Class 5/6) |

| Insulation | E | EPR insulated |

| Inner Sheath | PF | Thermoplastic Polyolefin(SHF1) |

| Armor | 9 | Galvanized Steel Wire Braid |

| Outer Sheath | 6 | Thermoplastic Polyolefin(SHF1) |

| Outer Sheath Color | / | Black or other Color |

| Flammability | SC | Halogen Free Low Smoke Flame Retardant |

Key Performance Characteristics

-

Superior EPR Insulation: Ethylene Propylene Rubber (EPR) provides outstanding dielectric strength, thermal stability, and long-term resistance to heat, moisture, and electrical stress, ensuring reliable power transmission.

-

Maximum Mechanical & Environmental Protection: The galvanized steel wire braid armor offers supreme defense against crushing, impact, and tensile stresses. The full SHF1 outer sheath encapsulates the armor, providing an additional robust barrier against abrasion, moisture, oils, chemicals, and corrosion.

-

Halogen-Free Enhanced Safety: Constructed with halogen-free, low-smoke materials (IEC 60754 & IEC 61034) and is flame retardant (IEC 60332). This safety package minimizes corrosive gas emission and smoke density during a fire, crucial for personnel safety in confined spaces.

-

High Flexibility: Despite its heavy-duty, fully protected design, the use of flexible Class 5/6 conductors ensures the cable retains essential flexibility for installation in complex cable management systems.

-

Comprehensive Durability: The combination of EPR insulation, dual-sheath, and steel armor ensures exceptional longevity and performance under the most severe operating conditions.

Standards & Compliance

This cable is designed and manufactured in strict compliance with key international marine and safety standards:

-

IEC 60092-350, 353 (General construction and tests)

-

IEC 60228 (Conductors)

-

IEC 60092-360 (Insulation and sheath materials)

-

IEC 60332-1 & IEC 60332-3-22 (Flame retardancy tests)

Typical Applications

This cable is specified for the most critical, physically exposed, and safety-sensitive installations:

-

Marine & Offshore: Vital power feeds to emergency systems, heavy deck machinery (cranes, winches), engine room auxiliary circuits, and control systems on ships and offshore platforms where cables face extreme mechanical abuse and environmental exposure.

-

Heavy Industry, Mining & Critical Infrastructure: Power and control wiring in mining operations, steel plants, power generation facilities, and processing plants where maximum resistance to physical damage, environmental factors, and stringent fire safety requirements are non-negotiable.