Product Overview

The CJPJR85/NC is a premium halogen-free, low-smoke, fire-resistant marine flexible power cable engineered for critical circuits that demand both certified circuit integrity during a fire and enhanced performance in elevated temperature environments. It features a mica glass tape and XLPE fire-resistant insulation system, a fully cross-linked polyolefin (SHF2) dual-sheath for superior thermal stability, and tinned copper wire braid armor for EMI shielding. This construction is ideal for essential safety systems in high-ambient-temperature areas on ships and offshore platforms.

Technical Specifications

-

Rated Voltage (U₀/U): 0.6/1 kV

-

Maximum Continuous Conductor Temperature: 90°C

-

Sheath Material (SHF2) Temperature Rating: Up to 105°C (Typical)

-

Conductor: Tinned or Plain Stranded Annealed Copper Wire (IEC 60228)

-

Available Cross-Sections: 0.75 mm² to 300 mm²

-

Core Configurations: 1 to 37 Cores

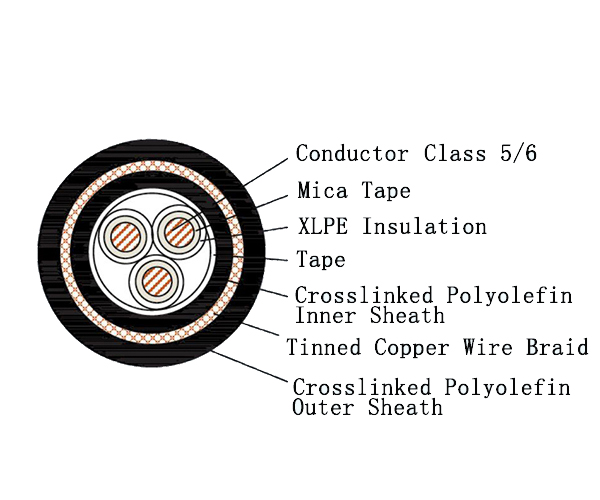

Cable Construction & Materials

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned/Plain Stranded, Annealed Copper Wire |

| Insulation | J | Mica Glass Tape + XLPE insulated |

| Inner Sheath | PJ | Cross-linked Polyolefin(SHF2) |

| Armor | 8 | Tinned/Plain Copper Wire Braided |

| Outer Sheath | 5 | Cross-linked Polyolefin(SHF2) |

| Outer Sheath Color | / | Black or other Color |

| Flammability | NC | Halogen Free Low Smoke Fire Resistant |

Key Performance Characteristics

-

Certified Fire Resistance (IEC 60331): The core insulation system is specifically designed to maintain circuit integrity and continue operating for a defined period under direct flame exposure, which is crucial for all emergency and life-safety systems.

-

Enhanced High-Temperature Sheath System: Both inner and outer sheaths utilize cross-linked polyolefin (SHF2), offering improved thermal endurance and resistance to deformation in higher ambient temperatures, ensuring long-term sheath integrity.

-

Complete Fire Safety Package: Integrates multiple safety standards: Fire Resistance (IEC 60331), Flame Retardancy (IEC 60332), zero halogen emission (IEC 60754), and low smoke density (IEC 61034). This maximizes personnel safety by limiting fire spread, toxic fumes, and smoke obscuration.

-

Effective EMI Shielding & Durability: The tinned copper wire braid armor provides reliable electromagnetic interference (EMI) shielding for sensitive control circuits. The tough, cross-linked outer sheath adds a layer of mechanical and environmental protection for the armor.

Standards & Compliance

This cable is manufactured in strict compliance with the highest international marine and fire safety standards:

-

IEC 60092-350, 353 (General construction and armor)

-

IEC 60228 (Conductors)

-

IEC 60092-360 (Insulation and sheath)

-

IEC 60331 (Fire Resistance)

-

IEC 60332-1 & IEC 60332-3-22 (Flame retardancy)

-

IEC 60754 (Halogen-free)

-

IEC 61034 (Low smoke density)

Typical Applications

This cable is specified for critical safety circuits where fire resistance must be combined with reliable performance in warmer environments and effective EMI shielding:

-

Marine & Offshore: Essential power and control circuits for emergency generators, fire pumps, alarm systems, and emergency lighting located in engine rooms, machinery spaces, or other areas with elevated ambient temperatures on ships, oil rigs, and offshore platforms.

-

Critical Infrastructure & Industrial Plants: Safety-critical wiring in power generation facilities, industrial process control rooms, and other installations where regulations mandate both certified fire-resistant cabling and enhanced temperature resistance for the cable sheath.