Product Overview

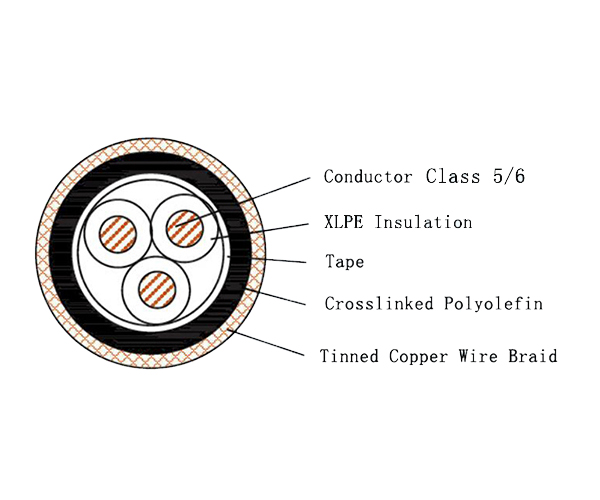

The CJPJR80/SC is a halogen-free, flame-retardant marine flexible power cable designed for applications requiring enhanced thermal resistance alongside flexibility and shielding. Its key differentiator is the use of a cross-linked polyolefin (SHF2) inner sheath, rated for higher temperatures. Combined with fine-stranded conductors, XLPE insulation, and tinned copper wire braid armor, it is ideal for demanding circuits in high-ambient-temperature areas or where superior mechanical and shielding performance is needed without an outer sheath.

Technical Specifications

-

Rated Voltage (U₀/U): 0.6/1 kV

-

Maximum Continuous Conductor Temperature: 90°C

-

Inner Sheath Material Temperature Rating: Up to 105°C (Typical for SHF2)

-

Conductor: Class 5/6 (Fine Strand) Tinned Annealed Copper Wire (IEC 60228)

-

Available Cross-Sections: 0.75 mm² to 300 mm²

-

Core Configurations: 1 to 37 Cores

Cable Construction & Materials

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Class 5/6(R) Tinned Annealed Copper Wire |

| Insulation | J | XLPE Insulated |

| Inner Sheath | PJ | Cross-linked Polyolefin(SHF2) |

| Armor | 8 | Tinned/Plain Copper Wire Braided |

| Outer Sheath | 0 | Without Outer Sheath |

| Flammability | SC | Halogen Free Low Smoke Flame Retardant |

Key Performance Characteristics

-

High-Temperature Resistant Inner Sheath: The cross-linked polyolefin (SHF2, PJ) inner sheath offers improved thermal endurance (typically up to 105°C) compared to standard thermoplastic sheaths, providing better performance in high-ambient-temperature environments.

-

Excellent Flexibility & Shielding: Utilizes fine-stranded (Class 5/6) tinned copper conductors for easy installation. The tinned copper wire braid armor provides effective electromagnetic shielding (EMC) and good flexibility.

-

Flame Retardant Safety: Complies with IEC 60332-1 and IEC 60332-3-22 for flame retardancy, inhibiting the spread of fire along the cable run.

-

Halogen Free & Low Smoke: The construction materials are halogen-free (IEC 60754) and generate low smoke density (IEC 61034), enhancing safety by reducing corrosive gas emission and improving visibility in case of fire.

-

Corrosion-Resistant Armor: Tinned copper braid offers reliable protection against corrosion in humid and saline marine atmospheres.

Standards & Compliance

This flexible cable is manufactured in accordance with the following international standards:

-

IEC 60092-350, 353 (General construction and tests for shipboard power cables)

-

IEC 60228 (Conductors of insulated cables)

-

IEC 60092-360 (Insulating and sheathing materials)

-

IEC 60332-1 & IEC 60332-3-22 (Tests for flame retardancy)

Typical Applications

This cable is particularly suited for flexible installations where higher temperature resistance or superior shielding is required:

-

Marine & Offshore: Internal wiring in control cabinets, instrumentation panels, and for equipment located in higher temperature zones (e.g., near engines or heat sources) on ships and oil platforms. The copper braid is ideal for sensitive control and signal circuits requiring EMI shielding.

-

Industrial: Power and control connections in industrial settings with elevated ambient temperatures or where electromagnetic interference must be minimized.