CJPJ95/NC XLPE Insulated Low-smoke Halogen-free Armored Marine Power Cable

Product Overview

The CJPJ95/NC represents the highest standard in marine cable design, offering an uncompromising combination of durability, safety, and performance for mission-critical circuits. Featuring a complete double-layer Cross-linked Polyolefin (SHF2) sheath system and robust galvanized steel wire armor, it provides the ultimate protection against mechanical damage, environmental hazards, and fire. Designed for vital power, lighting, and control systems in extreme offshore and industrial settings, it is the premier choice where failure is not an option.

Key Features

-

Ultimate Durability with SHF2: Utilizes Cross-linked Polyolefin (SHF2) for both inner and outer sheaths, delivering superior resistance to high temperatures, abrasion, chemicals, and long-term environmental degradation.

-

Maximum Mechanical Strength: Galvanized Steel Wire Braid Armor offers the highest level of protection against crushing, impact, and tensile stresses.

-

Certified Fire & Circuit Integrity: Fire Resistant (IEC 60331) to ensure continuous operation during fire emergencies, plus Flame Retardant (IEC 60332) properties to inhibit flame spread.

-

Personnel & Equipment Safety: Low-Smoke Halogen-Free (IEC 61034, IEC 60754) construction drastically reduces smoke density and eliminates the emission of toxic, corrosive gases.

-

Complete Environmental Sealing: The dual SHF2 sheath fully encapsulates the armor, providing a total barrier against moisture, oils, and corrosive agents.

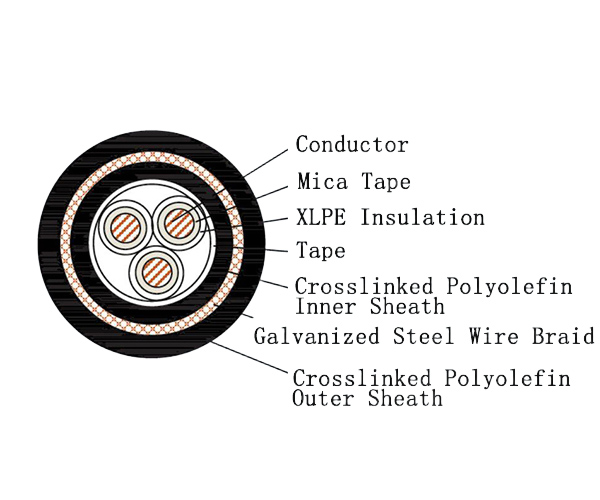

Construction Details

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned/Plain Stranded, Annealed Copper Wire |

| Insulation | J | Mica Glass Tape + XLPE Insulated |

| Inner Sheath | PJ | Cross-linked Polyolefin (SHF2) |

| Armor | 9 | Galvanized Steel Wire Braid |

| Outer Sheath | 5 | Cross-linked Polyolefin (SHF2) |

| Outer Sheath Color | / | Black or other Color |

| Flammability | NC | Halogen Free Low Smoke Fire Resistant |

Technical Specifications

-

Rated Voltage: 0.6/1 kV

-

Maximum Continuous Operating Temperature: 90°C

-

Conductor Cross-Sectional Area Range: 0.75 mm² to 300 mm²

-

Number of Cores: 1 to 37 Cores

Applicable Standards

-

IEC 60092-350, 353 – Design

-

IEC 60228 – Conductors

-

IEC 60092-360 – Insulation and Sheath

-

IEC 60331 – Fire Resistance

-

IEC 60332-1 – Flame Retardant (Single Cable)

-

IEC 60332-3-22 – Flame Retardant (Bunched Cables)

-

IEC 60754 – Halogen-free (Corrosivity of Gases)

-

IEC 61034 – Low Smoke Density

Typical Applications

-

Critical and emergency power feeders on offshore oil & gas platforms, FPSOs, and naval vessels.

-

Safety system wiring (fire pumps, emergency generators, alarms) in areas with severe mechanical and environmental challenges.

-

Heavy industrial complexes (mining, petrochemical, power generation) where the highest levels of cable durability and fire safety are mandated.

-

Infrastructure projects (tunnels, data centers, high-rises) requiring a premium, fully-certified cable solution for life safety systems.