CJPJ80/NC XLPE Insulated Low-smoke Halogen-free Armored Marine Power Cable

Product Overview

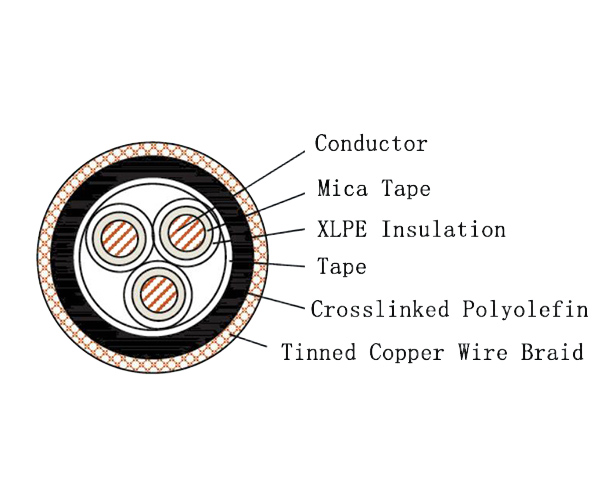

The CJPJ80/NC is a high-performance, fire-resistant marine power cable engineered for critical safety circuits. It combines superior fire integrity (IEC 60331) with low-smoke zero-halogen (LSZH) safety features and a flexible copper braid armor. The use of a Cross-linked Polyolefin (SHF2) inner sheath enhances its thermal and mechanical durability. Designed for essential power, lighting, and control systems in demanding offshore (e.g., oil platforms) and industrial environments (e.g., power plants, mining), it ensures reliability under extreme conditions.

Key Features

-

Enhanced Sheath Durability: Features a Cross-linked Polyolefin (SHF2) inner sheath, offering improved thermal stability, abrasion resistance, and longevity compared to standard thermoplastic sheaths.

-

Certified Fire Safety: Fire Resistant (IEC 60331) to maintain circuit operation during fire, plus Flame Retardant (IEC 60332) properties to prevent flame spread.

-

Critical Safety in Confined Spaces: Low-Smoke Halogen-Free (IEC 61034, IEC 60754) construction minimizes toxic and corrosive smoke emission, crucial for personnel safety.

-

Flexible Armor Protection: Tinned Copper Wire Braided Armor provides effective mechanical protection, EMI shielding, and excellent grounding while maintaining cable flexibility.

-

Robust Insulation System: Mica glass tape over XLPE insulation ensures circuit integrity and electrical performance in high-temperature scenarios.

Construction Details

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned/Plain Stranded, Annealed Copper Wire |

| Insulation | J | Mica Glass Tape + XLPE Insulated |

| Inner Sheath | PJ | Cross-linked Polyolefin (SHF2) |

| Armor | 8 | Tinned/Plain Copper Wire Braided |

| Outer Sheath | 0 | Without Outer Sheath |

| Flammability | NC | Halogen Free Low Smoke Fire Resistant |

Technical Specifications

-

Rated Voltage: 0.6/1 kV

-

Maximum Continuous Operating Temperature: 90°C

-

Conductor Cross-Sectional Area Range: 0.75 mm² to 300 mm²

-

Number of Cores: 1 to 37 Cores

Applicable Standards

-

IEC 60092-350, 353 – Design

-

IEC 60228 – Conductors

-

IEC 60092-360 – Insulation and Sheath

-

IEC 60331 – Fire Resistance

-

IEC 60332-1 – Flame Retardant (Single Cable)

-

IEC 60332-3-22 – Flame Retardant (Bunched Cables)

-

IEC 60754 – Halogen-free (Corrosivity of Gases)

-

IEC 61034 – Low Smoke Density

Typical Applications

-

Emergency power feeders and vital control circuits on offshore platforms and ships.

-

Wiring in engine rooms, switchboards, and other areas requiring flexible, fire-safe cabling with enhanced sheath durability.

-

Industrial safety systems in power generation, chemical, and metallurgy plants.

-

Applications where a cross-linked polyolefin (SHF2) sheath is specified for improved performance in higher temperature or more abrasive environments.