Product Overview

These indoor optical fiber cables with central strength member are engineered for reliable data transmission in ships, particularly in cruise ships where low smoke, halogen free and flame retardant cables are essential for enhanced onboard safety. Suitable for flexible installation on and below deck of commercial ships without constant exposure to oil, grease and other lubricants.

Technical Standards & Certifications

-

Marine Standards: IEC 60092-350/351/352/353/359/370/376

-

Flame Propagation: IEC 60332-1-2

-

Fire Performance: IEC 60332-3-22

-

Gas Emission: IEC 60754-1/2

-

Smoke Density: IEC 61034

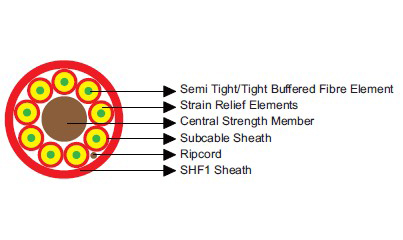

Cable Construction

-

Optical Fiber: Semi tight buffered or tight buffer

-

Strain Relief Elements: Aramid

-

Subcable Sheath: Halogen-free, flame-retardant compound

-

Central Strength Member

-

Outer Sheath: SHF1

Fiber Specifications

Geometric & Mechanical Properties

| Parameter | Unit | G50/125 (OM2) | G62.5/125 (OM1) | E9/125 (OS1) |

|---|---|---|---|---|

| Core Diameter | µm | 50 ± 2.5 | 62.5 ± 3 | - |

| Mode Field Diameter (at 1310 nm) | µm | - | - | 9.2 ± 0.4 |

| Cladding Diameter | µm | 125 ± 2 | 125 ± 1 | 125 ± 2 |

| Coating Diameter | µm | 245 ± 10 | 245 ± 5 | 245 ± 10 |

| Core Non-circularity | % | < 5 | < 5 | - |

| Cladding Non-circularity | % | < 1 | < 1 | < 1 |

| Core/Clad Concentricity Error | µm | < 1.5 | < 1.5 | < 0.8 |

| Eccentricity of Coating | µm | < 10 | < 10 | < 10 |

| Screen Test | - | ≥100 kpsi | ≥100 kpsi | ≥100 kpsi |

| Transmission Properties | - | OM2 | OM1 | OS1 |

Transmission Properties

| Parameter | Unit | G50/125 (OM2) | G62.5/125 (OM1) | E9/125 (OS1) | |||

|---|---|---|---|---|---|---|---|

| Wavelength | nm | 850 | 1300 | 850 | 1300 | 1310 | 1550 |

| Attenuation Max. | dB/km | 2.7 | 0.8 | 3.2 | 0.9 | 0.36 | 0.22 |

| Bandwidth Min. | MHz·km | 500 | 1000 | 250 | 600 | - | - |

| Effective Group of Refraction | - | 1.483 | 1.478 | 1.497 | 1.493 | 1.4695 | 1.4701 |

| Numerical Aperture | - | 0.200 ± 0.015 | - | 0.275 ± 0.015 | - | - | - |

| Dispersion Coefficient Max. | ps/nm·km | - | - | - | - | 3.5 | 18 |

| Zero Dispersion Wavelength | nm | - | - | - | - | 1300-1322 | - |

| Dispersion Slope | ps/nm²·km | - | - | - | - | ≤0.092 | - |

| Cutoff Wavelength (cabled) | nm | - | - | - | - | ≤1250 | - |

| Polarization Mode Dispersion | ps/km¹/² | - | - | - | - | ≤0.1 | - |

Mechanical & Thermal Properties

-

Bending Radius for Fixed Installations: 15× cable outer diameter

-

Temperature Range: -20℃ to +80℃

Dimensions & Weight

| Part Number | No. of Optical Fibers | Nominal Overall Diameter mm | Nominal Weight kg/km |

|---|---|---|---|

| MLN-MTA-X-2-H-F-H-CD/VT-A | 2 | 7.5 | 45 |

| MLN-MTA-X-4-H-F-H-CD/VT-A | 4 | 7.5 | 50 |

| MLN-MTA-X-6-H-F-H-CD/VT-A | 6 | 9.0 | 75 |

| MLN-MTA-X-8-H-F-H-CD/VT-A | 8 | 11.0 | 110 |

| MLN-MTA-X-10-H-F-H-CD/VT-A | 10 | 13.0 | 160 |

| MLN-MTA-X-12-H-F-H-CD/VT-A | 12 | 14.5 | 182 |

| MLN-MTB-X-16-H-F-H-CD/VT-A | 16 | 14.0 | 160 |

| MLN-MTB-X-18-H-F-H-CD/VT-A | 18 | 14.5 | 175 |

| MLN-MTB-X-20-H-F-H-CD/VT-A | 20 | 16.0 | 225 |

| MLN-MTB-X-24-H-F-H-CD/VT-A | 24 | 17.5 | 245 |

| MLN-MTB-X-26-H-F-H-CD/VT-A | 26 | 18.0 | 260 |

Fiber Type Coding (X in Part Number)

-

0: Fiber and copper conductors in cable

-

4: 50/125 multi-mode fiber (OM3)

-

5: 50/125 multi-mode fiber (OM2)

-

6: 50/125 multi-mode fiber (OM1)

-

7: NZDS SM fiber per G.656

-

8: NZDS SM fiber per G.655

-

9: Standard SM fiber per G.652.D

Features & Benefits

-

Central Strength Member: Enhanced mechanical stability and tensile strength

-

Aramid Reinforcement: Superior strain relief for demanding installations

-

Tight Buffered Design: Semi tight buffered or tight buffer fiber protection

-

Low Smoke Zero Halogen: SHF1 outer sheath for enhanced safety

-

Flame Retardant: Meets stringent IEC flame propagation standards

-

Wide Temperature Range: -20℃ to +80℃ operation

-

Compact & Lightweight: Optimized for space-constrained marine installations

-

Marine Certified: Full compliance with IEC 60092 series for shipboard use

Application Areas

-

Cruise ship indoor data networks

-

Commercial vessel communication systems

-

Shipboard control and monitoring networks

-

Marine automation and navigation systems

-

Offshore platform indoor data transmission

Note: These cables are designed for indoor installation on and below deck of commercial ships without constant exposure to oil, grease and other lubricants. All specifications comply with IEC 60092 standards for marine applications.