Product Overview

WTTC Cable is specifically engineered for wind turbine control applications, featuring UL certification and exceptional torsion resistance. Designed to withstand the demanding conditions of wind energy systems, this cable delivers reliable performance with superior mechanical and electrical properties for critical control circuits in turbine operations.

Key Features & Benefits

-

UL Certification: Fully certified to UL standards for guaranteed quality and safety compliance

-

Superior Torsion Performance: Withstands 10,000 torsion cycles (280-460°/3-5m) for dynamic applications

-

Enhanced Temperature Range: Operates from -40°C to +90°C in fixed installations

-

High Voltage Rating: 1kV rated with robust test voltage requirements (6kV-7.5kV)

-

Excellent Flame Resistance: FT4 flammability rating (Vertical Tray, UL 1277)

-

Reliable Shielding: Tinned copper braid shield with minimum 80% coverage for EMI protection

Applications

Critical control applications in wind energy systems:

-

Wind Turbine Control Systems: Primary control circuits in wind turbine operations

-

Turbine Monitoring: Sensor and monitoring system connections

-

Control Panel Wiring: Internal wiring of turbine control panels

-

Dynamic Applications: Systems requiring torsion resistance in moving components

-

UL-Compliant Installations: Applications requiring UL certification for safety standards

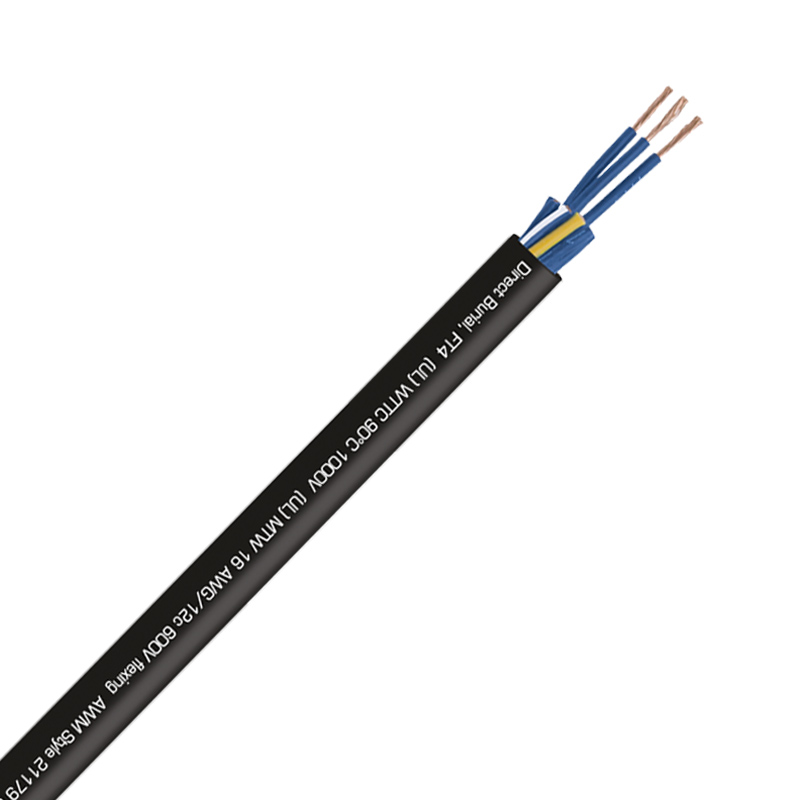

Construction

Advanced Construction for Wind Applications:

-

Conductor: Bare or tinned copper, UL 1581 Class K

-

Insulation: XLPE, core insulation in accordance with UL 44 & CSA C22.2 No. 38, EPR

-

Shield: Tinned copper braid shield (Minimum 80% coverage)

-

Sheath: Special XL compound (UL 1277 standard)

Technical Data

Performance Specifications:

-

Temperature Range:

-

Fixed: -40°C to +90°C

-

Flexing: -5°C to +90°C

-

-

Rated Voltage: 1kV

-

Test Voltage:

-

6kV (18-10 AWG)

-

7.5kV (8-2 AWG)

-

-

Minimum Bending Radius:

-

Fixed: 4 × Cable Diameter

-

Flexing: 10 × Cable Diameter

-

-

Flammability Rating: FT4 (Vertical Tray, UL 1277)

-

Torsion Requirement: 10,000 Cycles (280-460°/3-5m)

Product Specifications

Detailed Product List:

| Core Number × AWG | Outer Diameter | Copper Index |

|---|---|---|

| mm | kg/km | |

| 2×18AWG | 10.5 | 15.2 |

| 3×18AWG | 11.1 | 22.8 |

| 4×18AWG | 12.1 | 30.4 |

| 5×18AWG | 13.2 | 38.1 |

| 7×18AWG | 16.1 | 53.2 |

| 10×18AWG | 18.6 | 76.1 |

| 12×18AWG | 19.1 | 91.2 |

| 2×12AWG | 13.1 | 61.1 |

| 3×12AWG | 13.8 | 91.5 |

| 4×12AWG | 15.6 | 122.1 |

| 5×12AWG | 17.1 | 152.5 |

| 7×12AWG | 20.1 | 213.5 |

| 10×12AWG | 24.7 | 305.1 |

| 12×12AWG | 25.3 | 366.1 |

Key Advantages

-

Proven Reliability: Specifically designed and tested for wind turbine control applications

-

Comprehensive Certification: UL certified with compliance to multiple international standards

-

Exceptional Durability: Withstands extreme torsion cycles and wide temperature variations

-

Superior Safety: FT4 flame rating and robust construction ensure maximum safety

-

Optimized Performance: Balanced electrical and mechanical properties for control applications

-

Multiple Configurations: Various core arrangements to suit different control system requirements

-

Industry Standard Compliance: Meets UL 1277, UL 44, CSA C22.2 No. 38, and other relevant standards