5kV/8kV MC-HL MV-105 Industrial Shielded Power Cable 3×1/0 AWG | EPR Insulation, Copper Tape Shield, Yellow Jacket | Direct Burial & UL 1072/1569

Product Overview

5kV MC-HL MV-105 Power Cable: Industrial-Grade Power Distribution for Demanding Environments

Designed as an economical alternative to conduit systems, the 5kV MC-HL MV-105 cable delivers robust performance in industrial and utility power networks. Featuring EPR insulation, copper tape shielding, and a corrugated aluminum sheath, this 3x1/0 AWG cable excels in wet/dry locations, direct burial, and exposed installations while complying with UL 1072 and UL 1569 standards.

Key Specifications

-

Voltage Rating: 5kV (133% insulation level) / 8kV (100% insulation level)

-

Conductor: 3x1/0 AWG uncoated copper compact stranded (ASTM B-496)

-

Temperature Range: -40°C to +105°C

-

Certifications: FT4 Flame Retardant | Oil & UV Resistant | UL File E466020

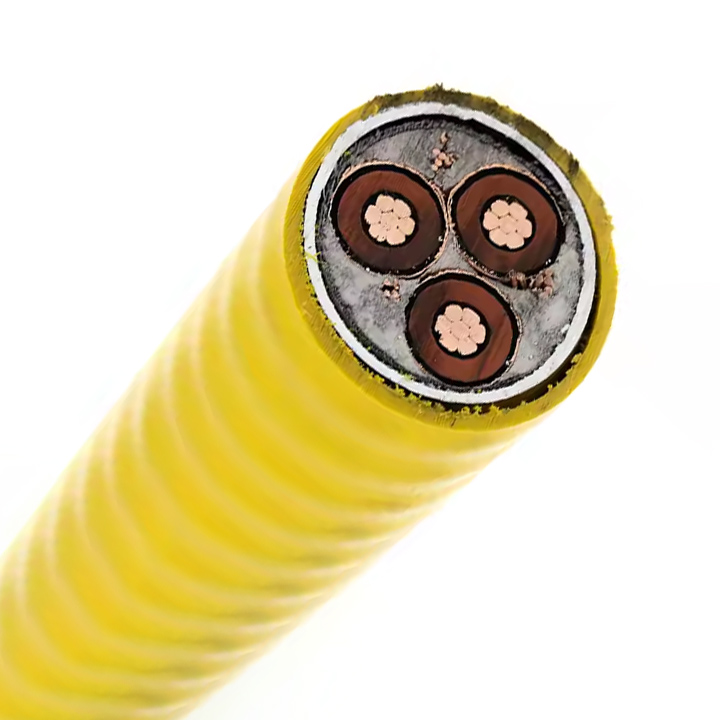

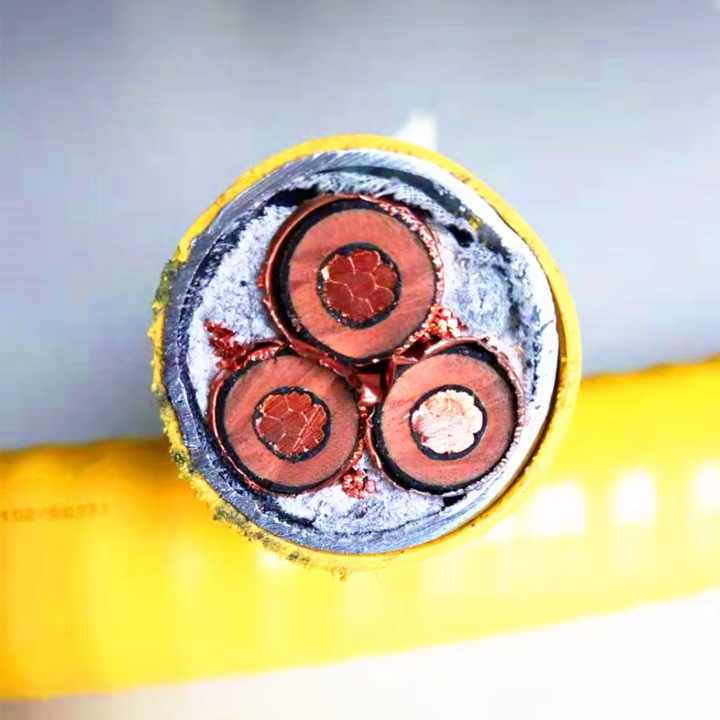

Cable Structure

| Layer | Material & Construction |

|---|---|

| 1. Conductor | 1/0 AWG compact stranded copper (ASTM B-496) |

| 2. Conductor Screen | Extruded semiconducting EPR |

| 3. Insulation | EPR (Ethylene Propylene Rubber) |

| 4. Insulation Screen | Extruded semiconducting EPR |

| 5. Shield | 5-mil copper tape, helical (12.5% overlap) |

| 6. Ground | 3x8 AWG bare copper (UL 1072 compliant) |

| 7. Fillers | Polypropylene (PP) |

| 8. Sheath | Corrugated impervious aluminum |

| 9. Jacket | Sunlight-resistant yellow PVC |

Technical Data for 3x1/0 AWG Configuration

| Parameter | Value |

|---|---|

| Insulation Thickness | 115 mil (2.92 mm) |

| Diameter Over Armor | 1.78 inches (45.2 mm) |

| Overall Diameter | 1.91 inches (48.5 mm) |

| Jacket Thickness | 60 mil (1.52 mm) |

| Net Weight | 2,462 lb/1000 ft |

| Ampacity (Air) | 205 A |

| Ampacity (Cable Tray) | 185 A |

| Ampacity (Direct Burial) | 245 A |

Applications

-

Industrial Plants: Feeders for motors, transformers, and switchgear.

-

Direct Burial: Underground power distribution without conduit.

-

Harsh Environments: Oil refineries, chemical processing (oil/UV resistant).

-

Concrete-Embedded: Foundations, tunnels, and infrastructure projects.

-

Cable Trays/Racks: Exposed runs with ≤6 ft support spacing.

Performance Advantages

-

Extended Lifespan

-

EPR insulation resists thermal degradation (105°C continuous).

-

-

EMI Protection

-

Copper tape shield + aluminum sheath block interference.

-

-

Moisture Resistance

-

Hermetic aluminum sheath prevents water ingress.

-

-

Safety Compliance

-

FT4 flame rating + integrated grounding (3x8 AWG).

-

-

Cost Efficiency

-

35% savings vs. conduit systems (labor + materials).

-

Standards & Compliance

-

UL Standards: UL 1072 (Shielded Power Cables), UL 1569 (Metal-Clad Cables)

-

Voltage Compliance: NEC 5kV/133% & 8kV/100% insulation levels

-

Environmental: UV-resistant jacket for outdoor exposure

Engineering Notes

-

Installation Flexibility: Suitable for vertical runs, trays, and concrete embedding.

-

Grounding: 3x8 AWG conductors meet NEC fault-current requirements.

-

Temperature Resilience: Operates in Arctic (-40°C) to high-heat industrial settings.