Product Overview

XLPE/EPR Insulated URD Cable (MV-90 & MV-105) delivers reliable power distribution for industrial networks up to 35kV. Engineered with triple-extruded XLPE or EPR insulation, thermosetting semiconductor screens, and copper-wire shielding, this cable excels in direct burial, duct, and wet/dry installations. Ideal for substations, refineries, and utility networks requiring ANSI/ICEA compliance and 105°C operational resilience.

Key Features

-

Voltage Rating: 5kV, 8kV, 15kV, 25kV, 35kV

-

Temperature Range:

-

MV-90: -40°C to +90°C (XLPE)

-

MV-105: -40°C to +105°C (EPR)

-

-

Conductor Options:

-

Aluminum (1350-H19 per ASTM B230/B231)

-

Annealed copper (ASTM B3/B8)

-

-

Shielding: Copper wire screen + dual semiconductor layers

-

Jacket: PVC or LLDPE (red/black) for abrasion/UV resistance

-

Installation: Direct burial, conduit, ducts, aerial (catenary)

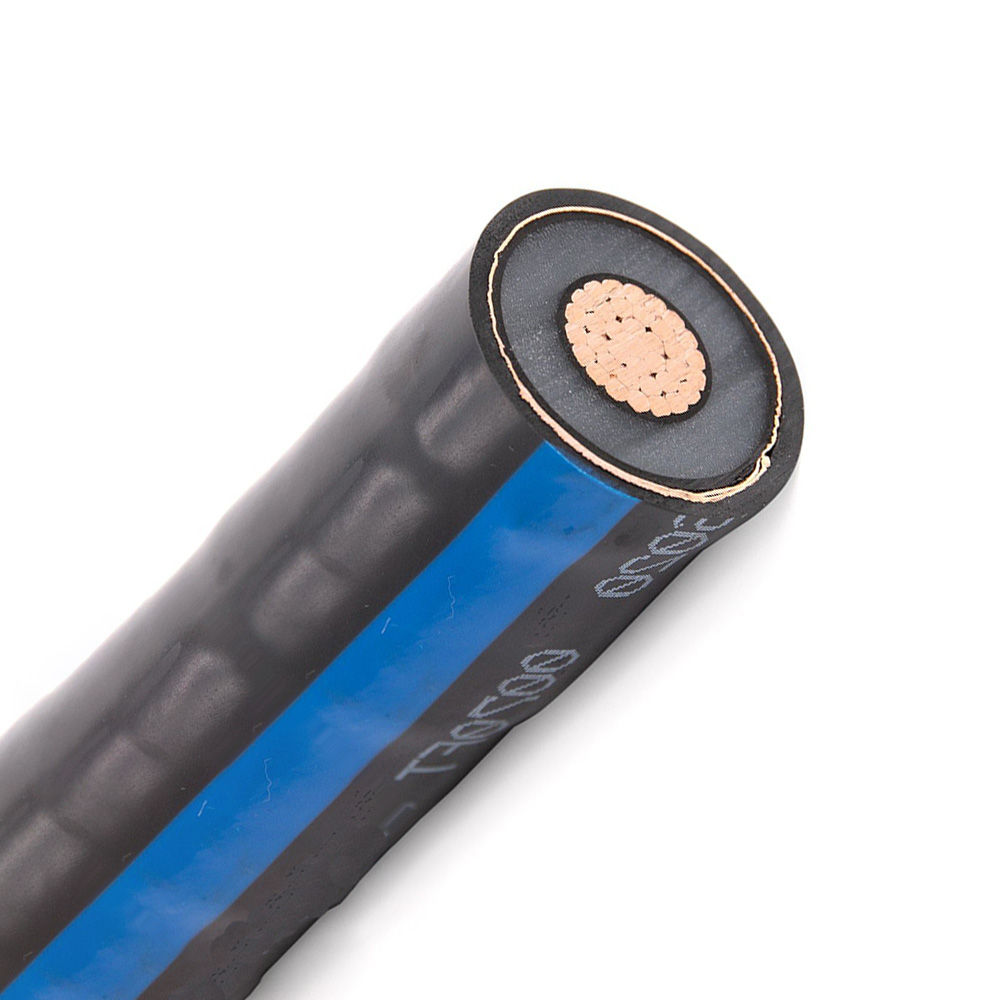

Cable Structure & Materials

| Layer | Material/Construction | Function & Properties |

|---|---|---|

| Conductor | Compact-stranded Al/Cu (ICEA S-94-649) | Low impedance, ASTM B231/B8 compliant |

| Conductor Screen | Thermosetting semiconductor | Equalizes electric field, voids-free interface |

| Insulation | XLPE or EPR (triple extrusion) | Dry-cured, moisture-resistant, 100% insulation integrity |

| Insulation Screen | Strippable thermosetting semiconductor | Smooth interface for termination |

| Metallic Shield | Copper wire concentric | Fault current capacity, EMI suppression |

| Outer Sheath | PVC/LLDPE (UV-stabilized) | Crush/chemical resistance, direct-burial rated |

Technical Parameters (Aluminum Conductor, 15kV)

| Size (kcmil) | Stranding | Insul. Thick (mils) | OD (mils) | Weight (lbs/1000ft) | Ampacity (Direct Burial) | Ampacity (Duct) |

|---|---|---|---|---|---|---|

| 250 | 37×16 | 175 | 963 | 1,213 | 360A | 257A |

| 350 | 37×18 | 175 | 1,068 | 1,055 | 389A | 319A |

| 500 | 37×25 | 175 | 1,193 | 1,349 | 468A | 384A |

| 750 | 61×24 | 175 | 1,383 | 1,946 | 569A | 468A |

| 1000 | 61×20 | 175 | 1,530 | 2,473 | 642A | 542A |

*Ampacity per NEC Table 310.60, 90°C conductor temp, 100% LF.

*Full size table (2-1500kcmil) available in datasheet.*

Material Advantages

-

XLPE Insulation:

-

Low dielectric loss, high dielectric strength (≥20kV/mm)

-

Tree-retardant for long service life in wet environments

-

-

EPR Insulation (MV-105):

-

Superior thermal resilience (+105°C continuous)

-

Flexibility at -40°C for arctic installations

-

-

Triple Extrusion: Bonded conductor/insulation/screen layers eliminate voids

-

Copper Wire Shield: 25kA fault current rating (1-sec)

Application Scenarios

-

Utility Networks:

-

Substation feeders, transformer connections, underground residential distribution

-

-

Heavy Industry:

-

Steel mill furnace power, refinery pump circuits, chemical plant HV systems

-

-

Renewable Energy:

-

Wind farm collector lines, solar substation interconnects

-

-

Infrastructure:

-

Airport runway lighting, tunnel electrification, wastewater treatment plants

-

-

Critical Systems:

-

Hospital generator backups, data center HV distribution

-

Compliance & Standards

| Standard | Certification | Scope |

|---|---|---|

| Primary | ANSI/ICEA S-94-649, AEIC CS-8 | URD cable construction & performance |

| Safety | UL 1072 | Fire/crush resistance |

| Conductor | ASTM B3 (Cu), ASTM B230/B231 (Al) | Material purity & stranding |

| Electrical | ICEA T-32-645 | Ampacity/voltage drop calculations |

| Environmental | RoHS 3, REACH | Hazardous substance free |

Ordering Information

Base Model: URD MV Power Cable

Specify:

-

Voltage: 5kV, 8kV, 15kV, 25kV, 35kV

-

Insulation: XLPE (MV-90) or EPR (MV-105)

-

Conductor:

-

Aluminum (1350 compact-stranded)

-

Copper (annealed, Class B/C)

-

-

Size: 250 kcmil to 1500 kcmil

-

Jacket: PVC (std) or LLDPE (enhanced moisture barrier)

-

Shielding: Copper wire screen (default) / Copper tape (optional)

Example:

15kV-EPR-AL-500kcmil-LLDPE= 15kV, EPR insulation, 500kcmil aluminum, LLDPE jacket

Engineering Tip: For direct burial in corrosive soils, specify LLDPE jacket + semiconductive tape outer layer. Use 100% insulation level for systems with ungrounded neutrals.