Product Overview

The KFF/KFG Series Industrial Heat-Resistant Control Cables provide reliable signal transmission in extreme industrial environments. Engineered with fluoroplastic (F46) insulation and multiple sheath options (fluoroplastic, silicone rubber, or PVC), these cables deliver superior thermal stability (up to +250°C), chemical resistance, and EMI protection for critical control, monitoring, and protection circuits in high-temperature zones and chemically aggressive settings.

Comprehensive Model Specifications

| Model | Insulation | Sheath Material | Shielding | Armor | Flexibility | Max Temp (°C) |

|---|---|---|---|---|---|---|

| KFF | Fluoroplastic | Fluoroplastic | None | None | Standard | 200 |

| KFFP | Fluoroplastic | Fluoroplastic | Copper Braid | None | Standard | 200 |

| KFFR | Fluoroplastic | Fluoroplastic | None | None | Flexible | 200 |

| KFFRP | Fluoroplastic | Fluoroplastic | Copper Braid | None | Flexible | 200 |

| KFV | Fluoroplastic | PVC | None | None | Standard | 105 |

| KFVP | Fluoroplastic | PVC | Copper Braid | None | Standard | 105 |

| KFVR | Fluoroplastic | PVC | None | None | Flexible | 105 |

| KFVRP | Fluoroplastic | PVC | Copper Braid | None | Flexible | 105 |

| KFV22 | Fluoroplastic | PVC | None | Steel Tape | Standard | 105 |

| KFVP22 | Fluoroplastic | PVC | Copper Braid | Steel Tape | Standard | 105 |

| KFVR22 | Fluoroplastic | PVC | None | Steel Tape | Flexible | 105 |

| KFVRP22 | Fluoroplastic | PVC | Copper Braid | Steel Tape | Flexible | 105 |

| KFG | Fluoroplastic | Silicone Rubber | None | None | Standard | 180 |

| KFGP | Fluoroplastic | Silicone Rubber | Copper Braid | None | Standard | 180 |

| KFGR | Fluoroplastic | Silicone Rubber | None | None | Flexible | 180 |

| KFGRP | Fluoroplastic | Silicone Rubber | Copper Braid | None | Flexible | 180 |

Flexibility Key: Standard = Hard Conductor • Flexible = Stranded Conductor (R-Suffix)

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 450/750V AC |

| Temperature Range | • Operating: -40°C to +250°C • Long-Term: Fluoroplastic Sheath: 200°C/250°C • Silicone Sheath: 180°C • PVC Sheath: 105°C |

| Bending Radius | • Non-Armored: ≥6× cable OD • Armored/Shielded: ≥12× cable OD • Flexible Shielded: ≥6× cable OD |

| Voltage Endurance | Passes 3kV AC (50Hz) for 5min without breakdown |

| Flame Performance | Flame-retardant (ZR) standard • Fire-resistant (NH) optional |

| Low-Temperature | • Fluoroplastic/Silicone: -40°C • PVC: -15°C |

Material Properties

| Component | Material | Key Advantages |

|---|---|---|

| Insulation | Fluoroplastic (F46) | • Acid/alkali/oil immunity • Non-flammable • Low smoke emission |

| Sheath | Fluoroplastic (F46) | Extreme chemical resistance (+200°C) |

| Silicone Rubber | Cold flexibility (-40°C) • Waterproof | |

| PVC | Mechanical protection • Cost efficiency | |

| Shielding | Copper Braid | EMI/RFI protection (90% coverage) |

| Armor | Steel Tape | Rodent/crush resistance |

Industry Applications

-

Petrochemical: Refinery control systems • Acid vapor zones

-

Metallurgy: Blast furnace instrumentation • Molten metal sensors

-

Power Plants: Turbine monitoring • Boiler control circuits

-

Mining: Underground conveyor controls • Explosive environments

-

Chemical Processing: Reactor instrumentation • Corrosive fluid handling

Engineering Selection Guide

-

Temperature Exposure

-

180°C: Fluoroplastic sheath (KFF/KFFP)

-

<-40°C: Silicone sheath (KFG/KFGR)

-

Moderate heat: PVC sheath (KFV series)

-

-

Chemical Hazards

-

Acids/oils: Fluoroplastic sheath

-

Moisture/steam: Silicone sheath

-

-

Mechanical Risks

-

Crushing/cutting: Steel tape armor (22-suffix)

-

-

Signal Integrity

-

EMI-sensitive: Copper braid shielding (P-suffix)

-

-

Mobility Requirements

-

Moving equipment: Stranded conductors (R-suffix)

-

Performance vs. Standard Cables

| Feature | KFF/KFG Series | Ordinary PVC Cables |

|---|---|---|

| Max Temp | +250°C | +70°C |

| Min Temp | -40°C | -15°C |

| Oil Resistance | 48h immersion (no degradation) | Swells/deforms |

| Acid Resistance | 20% H₂SO₄ resistant | Degrades |

| Bend Radius | 6× OD (flex models) | 10–15× OD |

| Flame Spread | Self-extinguishing | Requires additives |

Standards & Customization:

-

Complies with GB9330-88 (exceeds requirements)

-

Certifiable to IEC 60534-8 • BS 5308 • UL 1277

-

Custom options: Halogen-free (LSZH) • Fire-resistant (IEC 60331)

-

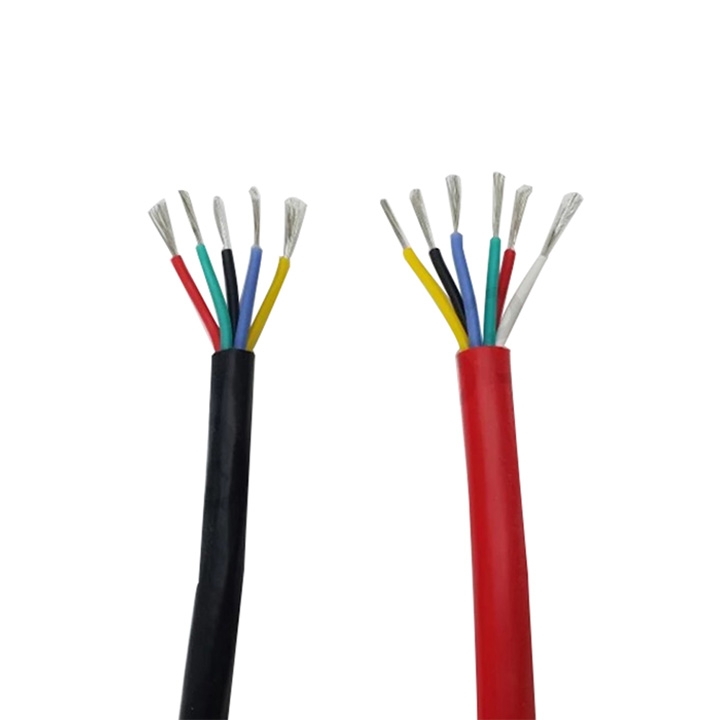

Conductor sizes: 0.5–10mm² • Color-coded per ANSI/ISO

Designed for mission-critical automation where temperature extremes and chemical exposure compromise standard cables, this series ensures signal integrity in the most demanding industrial environments.