Product Overview

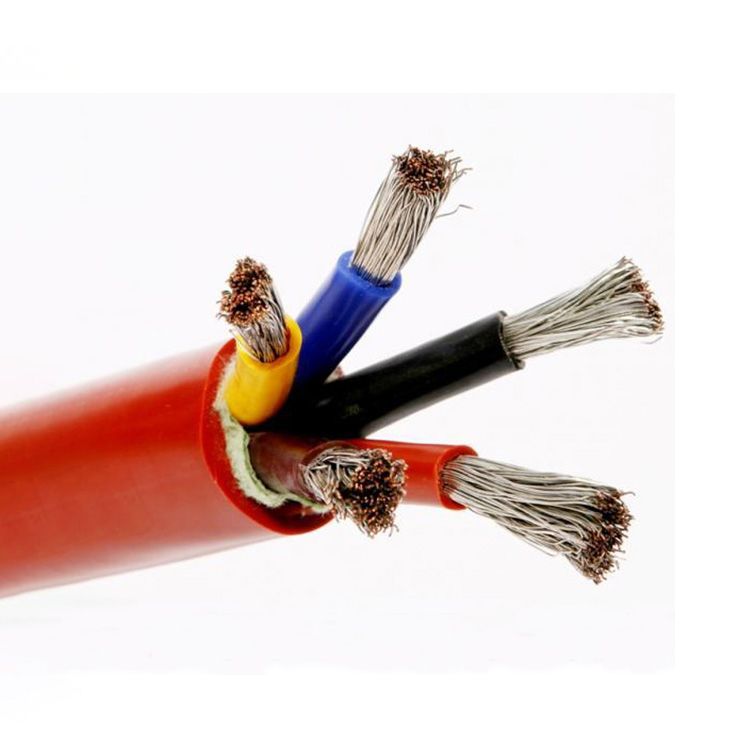

The YGC-F46(FG) Fluoroplastic F46 Insulated Silicone Rubber Sheathed Power Cable delivers superior performance in extreme industrial environments. Designed for fixed installations at 0.6/1kV AC, this cable combines F46 fluoroplastic insulation with silicone rubber sheathing to withstand temperatures up to +200°C while resisting chemicals, moisture, and mechanical stress. Ideal for high-heat power distribution in critical sectors like petrochemicals, metallurgy, and energy.

Complete Model Specifications

| Model | Insulation | Sheath Material | Shielding | Armor | Max Temp (°C) | Key Features |

|---|---|---|---|---|---|---|

| FF46 | F46 | Fluoroplastic | None | None | 200 | Basic high-temp |

| FF46-22 | F46 | Fluoroplastic | None | Steel Tape | 200 | Armored |

| FF46P | F46 | PVC | Copper Braid | None | 200 | Shielded |

| ZR-F46 (FV) | F46 | Flame-Retardant PVC | None | None | 105 | Flame-retardant |

| ZR-F46-22 (FV22) | F46 | Flame-Retardant PVC | None | Steel Tape | 105 | Armored + FR |

| ZR192-FF46 | PFA (Import) | PFA | None | None | 260 | Ultra-high temp |

| ZR192-FF46P | PFA (Import) | PFA | Copper Braid | None | 260 | Shielded + 260°C |

| ZR192-FF46-22 | PFA (Import) | PFA | None | Steel Tape | 260 | Armored + 260°C |

| YGC-F46 (FG) | F46 | Silicone Rubber | None | None | 180 | Flexible, chemical-resistant |

| FG22 | F46 | Silicone Rubber | None | Steel Tape | 180 | Armored + flexible |

| YVF-F46 | F46 | Nitrile Rubber | None | None | 105 | Oil-resistant |

| YVF-F46-22 | F46 | Nitrile Rubber | None | Steel Tape | 105 | Armored + oil-resistant |

Note: All models feature stranded copper conductors for flexibility

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1kV AC |

| Conductor | Stranded copper |

| Insulation | Fluoroplastic F46 |

| Sheath (FG Models) | Silicone Rubber |

| Temperature Range | • Continuous: -60°C to +200°C (insulation) / +180°C (silicone sheath) • Installation: ≥ -25°C |

| Bending Radius | • Single-core: ≥15× cable OD • Multi-core: ≥10× cable OD |

| Voltage Test | Withstands 3kV AC (50Hz) for 5min without breakdown |

| Flame Performance | Flame-retardant options (ZR) available |

| Standards Compliance | IEC 60502 • GB/T 12706 • Exceeds GB9330 |

Material Properties

| Component | Material | Key Advantages |

|---|---|---|

| Insulation | Fluoroplastic F46 | • Acid/alkali/oil immunity • Non-flammable (LOI >95%) • Low smoke emission |

| Sheath (FG) | Silicone Rubber | • Flexibility at -60°C • Waterproof/UV-resistant • Abrasion resistance |

| Conductor | Stranded Copper | • Vibration resistance • High current capacity |

| Armor (22) | Steel Tape | • Crush/cut protection • Direct burial capability |

Industrial Applications

-

Metallurgy: Power supply for arc furnaces, ladle cars (180°C ambient)

-

Petrochemical: Refinery pump wiring, acid vapor zones

-

Power Plants: Boiler feed systems, turbine hookups

-

Automotive: Paint shop ovens, curing lines

-

Heavy Machinery: Extruders, injection molding equipment

Engineering Selection Guide

-

Temperature Requirements

-

≤200°C: F46 insulation (YGC-F46)

-

200°C: PFA insulation (ZR192 series)

-

-

Chemical Exposure

-

Acids/oils: Fluoroplastic + silicone combo

-

Solvents: PFA variant

-

-

Mechanical Risks

-

Crushing: Steel tape armor (22-suffix)

-

Abrasion: Silicone sheath (8x tougher than PVC)

-

-

Environmental Factors

-

UV/moisture: Silicone sheath

-

Underground: Armored versions

-

Performance Comparison

| Parameter | YGC-F46(FG) | Standard XLPE Cable |

|---|---|---|

| Max Temp | +200°C | +90°C |

| Cold Flexibility | -60°C | -15°C |

| Chemical Resist | 48h in 30% H₂SO₄ | Fails in 24h |

| Bend Radius | 10× OD | 15× OD |

| Lifespan | 25+ years | 10–15 years |

Compliance & Certifications:

-

IEC 60502-1 • GB/T 12706.1

-

Flame-retardant: IEC 60332 • IEC 61034 (low smoke)

-

Customizable to UL 1277 • CSA C22.2

Optimized for critical power infrastructure in extreme environments, this cable ensures safety and reliability from blast furnaces to offshore platforms.