Product Overview

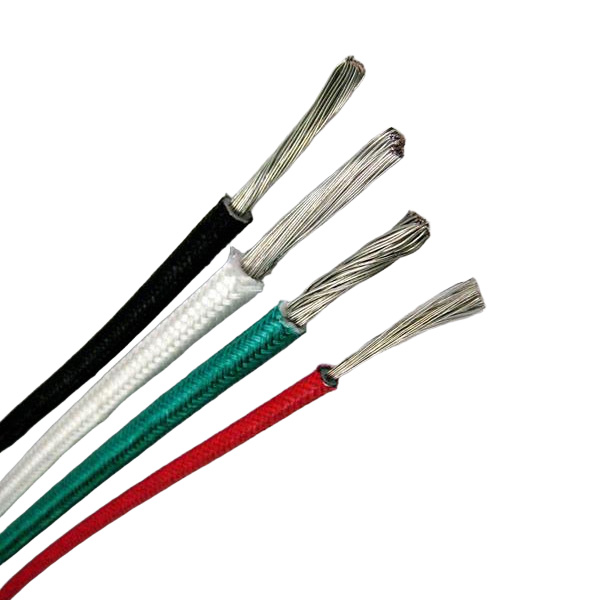

YG-series fiberglass-braided silicone rubber cables deliver extreme thermal resilience (-60°C to +180°C continuous, +500°C short-term) for harsh industrial environments. Featuring tinned copper conductors, silicone insulation, and woven fiberglass protection, these cables maintain flexibility and EMI resistance in foundries, kilns, and high-heat processing equipment.

Technical Specifications

| Parameter | Specification |

|---|---|

| Standards | VDE, IEC 60332, RoHS |

| Voltage Rating | 300V/500V AC |

| Temp Range | -60°C to +180°C (Peak: 500°C) |

| Conductor | Tinned Copper (Class 5/6) |

| Insulation | Silicone Rubber |

| Braid | Fiberglass Weave |

| Flame Rating | IEC 60332-1-2 (Self-extinguishing) |

| Bending Radius | 6× Cable Diameter |

| Colors | R/Y/B/W/Bk/G-Y/Br/O/P/G/Transparent |

Construction Details

1. Conductor

• Material: Tinned copper (99.99% electrolytic)

• Structure: Fine-stranded per IEC 60228 Class 5/6

• Plating: Tin layer ≥3μm for oxidation resistance

2. Insulation

• Material: High-temperature silicone rubber

• Thickness: 0.6-1.0mm (cross-section dependent)

• Properties: Maintains flexibility at -60°C

3. Braiding

• Material: E-glass fiber

• Weave Density: ≥90% coverage

• Function: Mechanical protection + EMI shielding

Material Properties

| Component | Key Characteristics | Test Standard |

|---|---|---|

| Silicone | Thermal stability @500°C (15min) | IEC 60811 |

| Fiberglass | Tensile strength ≥1,500 MPa | ISO 3341 |

| Tinned Cu | Conductivity ≥58 m/Ω·mm² | IEC 60228 |

Dimensional Data

| Size (mm²) | Stranding | Insul. Thk (mm) | Braid Thk (mm) | OD (mm) | Rdc (Ω/km) |

|---|---|---|---|---|---|

| 0.50 | 28 × 0.15 | 0.60 | 0.15 | 2.40 | 40.1 |

| 0.75 | 42 × 0.15 | 0.60 | 0.15 | 2.65 | 26.7 |

| 1.5 | 48 × 0.20 | 0.70 | 0.18 | 3.40 | 13.7 |

| 2.5 | 49 × 0.25 | 0.80 | 0.18 | 4.00 | 8.21 |

| 6.0 | 84 × 0.30 | 0.80 | 0.20 | 5.20 | 3.39 |

| 16.0 | 126 × 0.40 | 1.00 | 0.25 | 9.00 | 1.24 |

Application Scenarios

Extreme Heat Industries

• Steel mill ladle crane wiring

• Glass furnace sensor lines

• Ceramic kiln internal wiring

High-Temperature Equipment

• Industrial sauna heaters

• Foundry burner ignition systems

• Semiconductor diffusion ovens

EMI-Sensitive Environments

• Induction heating power supplies

• Electric arc furnace controls

• Welding robot cabling

Engineering Selection Guide

| Factor | Calculation Method | Critical Values |

|---|---|---|

| Current Rating | IEC 60512-5-51 Table A.16 | Derate 15%/50°C >180°C |

| Voltage Drop | ΔU = (I × L)/(κ × S) | Max 5% @ 300V rating |

| Thermal Cycling | DIN 5510 | 200 cycles @ -60↔500°C |

| Abrasion | ISO 6722 | >500 cycles @ 50N load |

⚠️ Installation Requirements

• Minimum bend radius: 6× cable OD

• Maximum vertical run: 30m (support every 1.5m)

• Avoid contact with molten metal splash zones

Compliance & Certifications

• Electrical Safety: VDE 0250, IEC 60332-1-2

• EMC Performance: EN 50289-1-6

• Environmental: RoHS 3, REACH SVHC

• Material Standards: IEC 60811 (Silicone), ISO 2078 (Fiberglass)