Product Overview

Type SHD Power, Flat Portable W/Ground Cable is a heavy-duty trailing cable engineered for harsh mining and industrial environments. Rated for 2000V and 90°C operation, this three-conductor cable features flame-retardant EPR insulation, reinforced CPE jacket, and a flexible copper/textile braid shield for shock hazard protection. Compliant with ICEA S-75-381 and MSHA standards, it delivers exceptional resistance to oil, chemicals, heat, and mechanical stress, making it ideal for AC mining equipment and high-risk applications.

Key Features

-

Mining-Grade Durability: Flame-retardant EPR/CPE construction withstands abrasion, oil, and radiation.

-

Shock Hazard Protection: Flexible copper/textile braid shield over non-conductive tape for safe operation.

-

Flat Design: Optimized for trailing applications with easy handling and reduced tangling.

-

MSHA Certification: Approved for use in underground mining and hazardous locations.

-

Triple Safety: Two shaped grounding conductors + semi-conducting shield for enhanced grounding reliability.

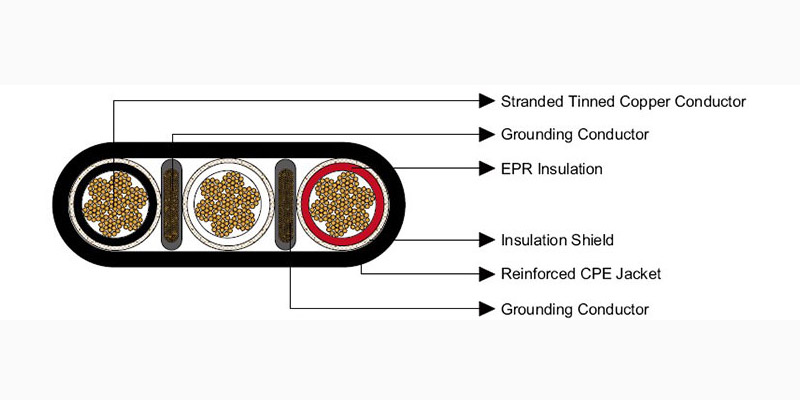

Construction Details

| Component | Specification |

|---|---|

| Conductor | 2/0 AWG or 3/0 AWG rope-lay-stranded coated copper (ASTM B172 compliant). |

| Insulation | Ethylene Propylene Rubber (EPR), flame-retardant and heat-resistant. |

| Insulation Shield | Copper/textile braid over non-conductive overlapped tape. |

| Grounding Conductors | Two shaped, coated copper conductors with semi-conducting extruded shield. |

| Jacket | Reinforced lead-cured Chlorinated Polyethylene (CPE), oil/chemical resistant. |

| Voltage Rating | 2000V AC. |

| Temperature Range | -40°C to +90°C (wet/dry). |

Technical Specifications

-

Standards Compliance: ICEA S-75-381, MSHA P-184, ASTM B172.

-

Flame Resistance: Meets MSHA flame test requirements (UL VW-1 equivalent).

-

Conductor Sizes: 2/0 AWG or 3/0 AWG (custom sizes available).

-

Environmental Resistance: Oil, steam, chemicals, UV, and abrasion.

-

Shielding: Dual-layer insulation shield for voltage hazard mitigation.

Applications

Type SHD Power Cable is engineered for:

-

Mining Operations: Trailing cables for AC-powered drills, shovels, and haulers.

-

Heavy Machinery: Draglines, excavators, and underground vehicles.

-

Industrial Plants: High-voltage equipment in chemical or oil-refining facilities.

-

Tunneling & Construction: Rugged power feeds in confined, high-vibration spaces.

-

Hazardous Locations: Areas requiring shielded cables to prevent electrical hazards.

Installation Guidelines

-

Bending Radius: Minimum 10x cable height to avoid shield/jacket damage.

-

Grounding: Ensure proper bonding of shield and grounding conductors per MSHA/NEC.

-

Pulling Tension: Use MSHA-approved grips to prevent conductor deformation.

-

Prohibited Uses: Avoid sharp edges or continuous flexing beyond design limits.

-

Storage: Coil flat to maintain shape and prevent kinking.

Why Choose Type SHD Power Cable?

-

Safety First: Shields mitigate induced voltages and shock risks in mining systems.

-

Extreme Durability: Reinforced CPE jacket resists cuts, tears, and environmental wear.

-

Regulatory Assurance: MSHA and ICEA compliance for legal and operational safety.

-

Flexibility: Flat, flexible design simplifies deployment in tight spaces.

-

Longevity: EPR insulation ensures thermal stability under continuous 90°C loads.

| NO. OF COND. | COND. SIZE (AWG) | COND. STRAND | NOMINAL INSULATION THICKNESS | GRD. COND. SIZE (AWG) | NOMINAL CABLE DIMENSIONS | NET WEIGHT (kg/km) | |

|---|---|---|---|---|---|---|---|

| INCHES | mm | ||||||

| 3 | 2/0 | 329 | 0.08 | 2 | 3 | 30.0 × 76.0 | 4980 |

| 3 | 3/0 | 413 | 0.08 | 2 | 2 | 31.8 × 83.6 | 5789 |