Product Overview

The 3-Core Silicone Rubber Cable (YGC Series) delivers exceptional reliability in demanding environments. Utilizing dual-layer silicone rubber insulation and sheath applied via advanced extruded tube technology, this cable ensures superior waterproofing, chemical resistance, thermal stability (-60°C to +200°C), and mechanical durability. Ideal for fixed installations and flexible applications in harsh industrial settings requiring robust performance under extreme conditions. Compliant with IEC 60245, GB/T 5013.8, and BS 6500 standards.

Key Features & Benefits

-

Dual-Layer Silicone Construction: Insulation + sheath for maximum environmental protection.

-

Extruded Tube Technology: Ensures seamless waterproofing, enhanced insulation integrity, and resistance to penetration.

-

Wide Temperature Range: -60°C to +200°C continuous operation (higher models available).

-

Superior Chemical Resistance: Withstands acids, alkalis, oils, ozone, and moisture.

-

Exceptional Durability: UV resistant, radiation resistant, cold-resistant, and anti-aging.

-

High Flexibility: Maintains pliability for routing in confined spaces.

-

Rated Voltage: 0.6/1kV (Standard).

-

Flame Retardant Options: Available (ZR- prefix models).

-

Conductor Options: Bare copper or tinned copper (enhanced corrosion resistance).

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Voltage | 0.6/1 kV (U<sub>0</sub>/U) |

| Temp. Range | -60°C to +200°C (Standard) |

| Insulation | Silicone Rubber (Grade: G) |

| Sheath | Silicone Rubber (Grade: G) |

| Conductor | Class 5 Flexible Stranded Copper (Bare or Tinned) |

| Core Count | 3 Cores (+ Optional Ground) |

| Shielding | Available (YGCP Models: Copper Braid) |

| Armoring | Available (YGG2G Models: Steel Tape) |

| Flame Retardant | ZR- Series Models Available |

| Standards | IEC 60245, GB/T 5013.8, BS 6500 |

Model Variants & Nomenclature

| Model Code | Product Name | Key Feature |

|---|---|---|

| YGC | Silicone Rubber Insulated & Sheathed Power Cable | Standard Construction |

| YGCR | Silicone Rubber Insulated & Sheathed Flexible Cable | High Flexibility (Mobile Use) |

| YGCP | Silicone Rubber Insulated & Sheathed Shielded Cable | Copper Braid Shielding (EMI/RFI) |

| YGG2G | Silicone Rubber Insulated & Sheathed Armored Cable | Steel Tape Armor (Mechanical Prot.) |

| JGG | Silicone Rubber Insulated & Sheathed Installation Cable | Fixed Wiring |

| JGGR | Silicone Rubber Flexible Installation Cable | Flexible Fixed Wiring |

| JGGP | Silicone Rubber Shielded Installation Cable | Shielded Fixed Wiring |

Code Key:

-

Y: Movable/Flexible Cable Series

-

G: Silicone Rubber Material

-

C: Heavy Duty

-

R: Highly Flexible Stranded Conductor

-

P: Copper Braid Shield

-

2: Steel Tape Armor

-

ZR: Flame Retardant (Prefix)

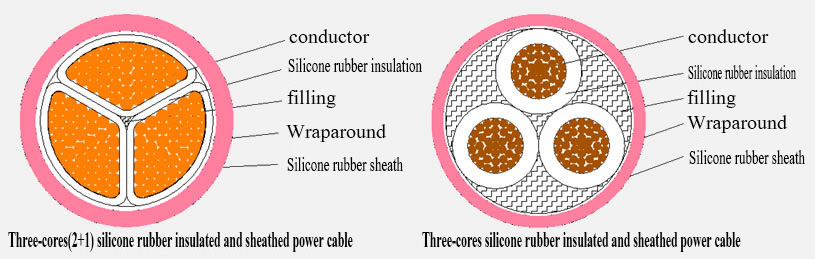

Construction Details

-

Conductor: Class 5 finely stranded copper wire (IEC 60228). Tinned option available for corrosive environments.

-

Insulation: High-temperature silicone rubber (Grade G) extruded uniformly via tube process, ensuring excellent dielectric strength and environmental sealing.

-

Core Identification: Color-coded cores (Customizable: Black/Red/Yellow or numbered).

-

Filling (Optional): Non-hygroscopic material for core bedding and roundness.

-

Shielding (YGCP/JGGP): Electrically continuous copper braid (≥85% coverage) for EMI/RFI protection.

-

Armoring (YGG2G): Double-layer galvanized steel tape armor (corrosion/impact protection).

-

Sheath: High-grade silicone rubber (Grade G) extruded over core assembly, providing abrasion, chemical, UV, and temperature resistance. Flame-retardant compound used in ZR- models.

Application Scenarios

-

Industrial Machinery: Power feeds for motors, pumps, generators in steel mills, foundries, smelters.

-

High-Temperature Zones: Ovens, furnaces, kilns, heating tunnels, boiler rooms.

-

Corrosive Environments: Chemical plants, petrochemical refineries, wastewater treatment.

-

Outdoor/Harsh Conditions: Solar farms, mining equipment, port machinery, coastal installations.

-

Equipment Requiring Shielding (YGCP): VFD cables, CNC machines, sensitive instrumentation.

-

Mechanically Stressed Areas (YGG2G): Direct burial, cable trays subject to impact, mining operations.

-

Fixed Installations (JGG/JGGR): High-temp plant wiring, control panels.

Selection & Ordering Guide

-

Specify Model: Choose core construction (YGC, YGCP, YGG2G, JGG, etc.).

-

Select Conductor: Standard copper or tinned copper (specify "Tinned" if required).

-

Indicate Voltage: 0.6/1kV standard (confirm if other ratings needed).

-

Core Size: Specify cross-sectional area (mm²) per core.

-

Length: Required cable length.

-

Special Requirements:

-

Flame retardant (ZR- prefix)

-

Core colors (e.g., Brown/Black/Grey/Yellow-Green)

-

Custom shielding/armoring specs

-

Special certifications (UL, CSA, etc.)

-