CKJP96/NC Fire Resistant Low Smoke Halogen Free (LSHF) Screened Marine Control Cable - XLPE Insulated - IEC 60092 Certified

Product Overview

The CKJP96/NC is a premium-grade, fire performance marine control cable designed for critical power, lighting, and control circuits in demanding offshore and onshore environments. Engineered with XLPE insulation and comprehensive fire safety features (Low Smoke Halogen Free, Fire Resistant, Flame Retardant), it ensures maximum safety, reliability, and signal integrity even under extreme conditions. Its robust screened and armored construction provides excellent EMI/RFI protection and mechanical resilience.

Key Applications

-

Offshore Platforms: Power, lighting, and essential control systems on oil & gas platforms and other offshore structures.

-

Shipboard Systems: Critical control circuits, alarm systems, and instrumentation wiring on ships and vessels.

-

Harsh Industrial Environments: Power plants, chemical processing plants, metallurgical facilities, and mines requiring enhanced fire safety and durability.

-

Onshore Marine Infrastructure: Control systems for docks, harbors, and coastal power installations.

Compliance & Standards

This cable is designed and tested to meet the highest international marine and fire safety standards:

-

Design: IEC 60092-350, IEC 60092-376

-

Conductor: IEC 60228

-

Insulation & Sheath: IEC 60092-360

-

Fire Resistance: IEC 60331 (Circuit integrity during fire)

-

Flame Retardancy: IEC 60332-1 (Single cable vertical flame test) & IEC 60332-3-22 (Category A bundled cable flame test - severe)

-

Halogen Free: IEC 60754-1 & -2 (Low acidity/corrosivity & low halogen gas emission)

-

Low Smoke Density: IEC 61034-1 & -2 (Reduced obscuration during fire)

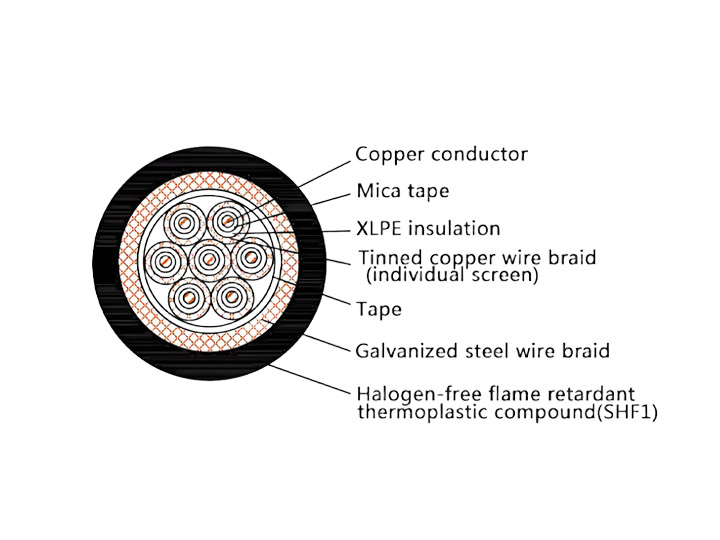

Cable Construction (Detailed)

The CKJP96/NC features a meticulously engineered layered structure for optimal performance:

-

Conductor:

-

Material: Annealed Copper

-

Type: Stranded (Flexible)

-

Finish: Tinned or Plain (Typically tinned for marine corrosion resistance)

-

Standard: IEC 60228 (Class 2 or 5 depending on stranding)

-

-

Insulation:

-

Material: Cross-Linked Polyethylene (XLPE)

-

Fire Performance Layer: Mica Glass Tape Applied Over XLPE Insulation (Critical for IEC 60331 Fire Resistance)

-

Key Properties: Excellent electrical properties, high temperature resistance, good chemical resistance.

-

-

Screen (Overall):

-

Type:

P- Electromagnetic Screening -

Construction: Tinned Copper Wire Braid OR Aluminum/Polyester Composite Tape with Integrated Tinned Copper Drain Wire.

-

Function: Provides effective EMI/RFI shielding for signal integrity and protection against electrical interference.

-

-

Armor:

-

Type:

9- Mechanical Protection -

Material: Galvanized Steel Wire Braid (GSWB)

-

Function: Superior resistance to crushing, impact, cut-through, and rodent attack. Provides earthing path.

-

-

Outer Sheath:

-

Type:

6- Environmental & Safety Protection -

Material: Halogen-Free Flame Retardant (HFFR) Thermoplastic Compound (Specific Grade: SHF1)

-

Flammability Class:

NC(Halogen Free Low Smoke Fire Resistant - confirming compliance with IEC 60754, IEC 61034, and IEC 60331) -

Color: Standard Black (Other colors available on request)

-

Key Properties: Excellent flame retardancy (IEC 60332-1 & -3-22), very low smoke emission (IEC 61034), no corrosive/toxic halogen gases (IEC 60754), good weathering, oil resistance, and mechanical toughness.

-

Material & Performance Characteristics

-

Fire Safety Excellence: Combines IEC 60331 Fire Resistance (circuit integrity), IEC 60332 Flame Retardancy (prevent fire spread), IEC 60754 Halogen Free (non-toxic, non-corrosive smoke), and IEC 61034 Low Smoke Density (visibility during evacuation/maintenance).

-

High Temperature Rating: Continuous operational temperature up to 90°C.

-

Enhanced Durability: Steel wire braid armor offers outstanding mechanical protection. XLPE insulation provides robust electrical and environmental resistance.

-

Signal Integrity: Effective overall screen minimizes electromagnetic interference.

-

Corrosion Resistance: Tinned copper conductors/braid and galvanized steel armor ensure longevity in salty, humid marine atmospheres.

-

Environmental Safety: Halogen-free sheath minimizes toxic hazards during combustion.

Technical Specifications

-

Rated Voltage (Uo/U): 150/250 V

-

Maximum Conductor Operating Temperature: 90°C

-

Conductor Cross-Sectional Area Range: 0.5 mm², 0.75 mm², 1.0 mm², 1.5 mm², 2.5 mm²

-

Number of Cores: 1 Core to 37 Cores

-

Insulation Material: XLPE + Mica Glass Tape (Fire Resistant Layer)

-

Screening: Tinned Copper Braid OR Al/PET Tape + Drain Wire

-

Armoring: Galvanized Steel Wire Braid (GSWB)

-

Sheath Material: Halogen-Free Flame Retardant (HFFR) Thermoplastic (SHF1)

-

Sheath Color: Standard Black (Other colors optional)

-

Flammability Class: NC (Halogen Free, Low Smoke, Fire Resistant - per IEC standards)

-

Key Standards Met: IEC 60092-350, 376, 360; IEC 60228; IEC 60331; IEC 60332-1 & -3-22; IEC 60754; IEC 61034

Engineering Selection Notes

-

Ideal For: Critical circuits where maintaining functionality during fire (IEC 60331) and minimizing smoke/toxicity (IEC 61034/60754) are paramount. Essential for offshore platforms, engine room controls, emergency systems, and confined spaces.

-

Robustness: The GSWB armor makes it suitable for areas exposed to significant mechanical stress.

-

EMI Sensitivity: The overall screen is crucial for control signals susceptible to interference.

-

Certification: Specify required Type Approvals during inquiry (e.g., specific Classification Society approvals).