Product Overview

The CEPJR95/SC represents the pinnacle of performance and protection in halogen-free marine flexible power cables. Engineered for the most critical and demanding applications, it combines superior Ethylene Propylene Rubber (EPR) insulation with a fully cross-linked polyolefin (SHF2) dual-sheath system and galvanized steel wire braid armor. This construction delivers unmatched electrical reliability, exceptional thermal endurance for the sheath in high-ambient-temperature environments, and maximum mechanical protection for vital circuits in the harshest marine and industrial settings.

Technical Specifications

-

Rated Voltage (U₀/U): 0.6/1 kV

-

Maximum Continuous Conductor Temperature: 90°C

-

Sheath Material (SHF2) Temperature Rating: Up to 105°C (Typical)

-

Conductor: Tinned or Plain Stranded, Annealed Copper Wire (Class 5/6 flexible) (IEC 60228)

-

Available Cross-Sections: 0.75 mm² to 300 mm²

-

Core Configurations: 1 to 37 Cores

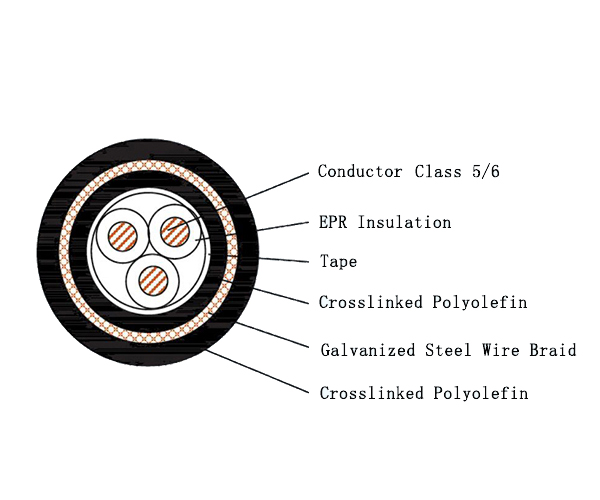

Cable Construction & Materials

| Item | Code | Material / Description |

|---|---|---|

| Series Code | C | Marine Power Cable |

| Conductor | / | Tinned/Plain Stranded, Annealed Copper Wire (Flexible Class 5/6) |

| Insulation | E | EPR insulated |

| Inner Sheath | PJ | Cross-linked Polyolefin(SHF2) |

| Armor | 9 | Galvanized Steel Wire Braid |

| Outer Sheath | 5 | Cross-linked Polyolefin(SHF2) |

| Outer Sheath Color | / | Black or other Color |

| Flammability | SC | Halogen Free Low Smoke Flame Retardant |

Key Performance Characteristics

-

Superior EPR Insulation: Ethylene Propylene Rubber (EPR) provides outstanding dielectric strength, excellent long-term thermal stability, and high resistance to moisture and electrical stress, ensuring reliable power transmission.

-

Complete High-Temperature Sheath System: Features a dual-sheath system (inner and outer) entirely made of cross-linked polyolefin (SHF2). This offers superior thermal endurance, deformation resistance, and longevity in elevated ambient temperature environments.

-

Maximum Mechanical & Environmental Protection: The galvanized steel wire braid armor provides supreme defense against crushing, impact, and tensile stresses. The tough, cross-linked outer sheath fully encapsulates the armor, offering an additional robust barrier against abrasion, moisture, oils, and chemicals.

-

Halogen-Free Enhanced Safety: Constructed with halogen-free, low-smoke materials and is flame retardant (IEC 60332). This safety package minimizes corrosive gas and smoke emission during a fire, which is crucial for personnel safety in confined spaces.

-

High Flexibility: Utilizes flexible Class 5/6 conductors, ensuring the cable remains manageable for installation despite its heavy-duty, fully protected construction.

Standards & Compliance

This cable is designed and manufactured in accordance with key international marine and safety standards:

-

IEC 60092-350, 353 (General construction and tests)

-

IEC 60228 (Conductors)

-

IEC 60092-360 (Insulation and sheath materials)

-

IEC 60332-1 & IEC 60332-3-22 (Flame retardancy tests)

Typical Applications

This cable is specified for the most critical, physically exposed, and thermally challenging installations:

-

Marine & Offshore: Vital power feeds to emergency systems, heavy deck machinery (cranes, winches), and engine room circuits on ships and offshore platforms where cables face extreme mechanical abuse and high ambient temperatures.

-

Heavy Industry & Critical Infrastructure: Power and control wiring in power generation plants, steel mills, and processing facilities where maximum resistance to physical damage, environmental factors, and stringent fire safety requirements are essential.