IEC 60502-1 Compliant AWA XLPE/PVC Armoured Cable (0.6/1kV)

Product Overview

Designed for versatile power distribution in demanding environments, this single-core aluminum wire armoured (AWA) cable combines XLPE insulation with PVC sheathing for reliable performance in diverse installation conditions. Manufactured to international standard IEC 60502-1:2004, it delivers robust power transmission for industrial, commercial, and infrastructure applications.

Key Features & Benefits:

-

Robust Armouring: AWA (Aluminium Wire Armour) provides mechanical protection while remaining non-magnetic - ideal for EMI-sensitive applications

-

Thermal Performance: XLPE (Cross-Linked Polyethylene) insulation enables higher current ratings and 90°C operational temperature

-

Environmental Resistance: PVC bedding and sheath offer moisture, chemical, and UV resistance

-

Installation Flexibility: Suitable for direct burial, ducting, indoor, and outdoor use

-

Rated Voltage: 600/1000V (U₀/U) for power networks

-

Conductor: Plain annealed stranded copper (Class 2 stranding)

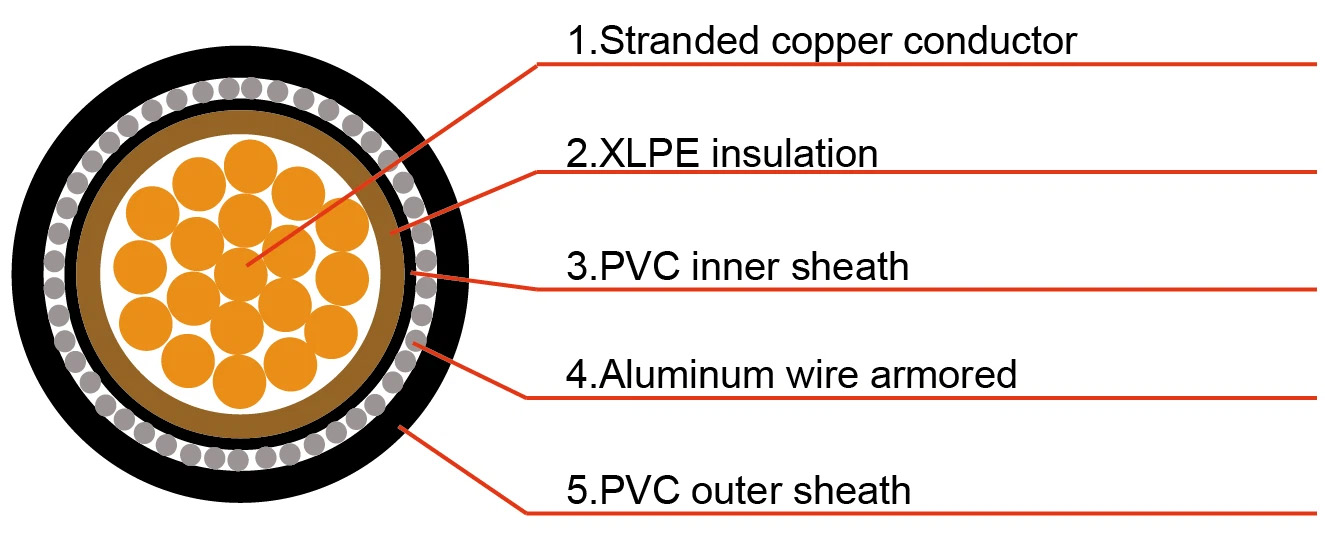

Product Structure:

-

Conductor: Plain annealed copper, Class 2 stranded (circular/compacted), brown identification

-

Insulation: XLPE (Cross-Linked Polyethylene)

-

Bedding: PVC layer

-

Armour: AWA (Aluminium Wire Armour) - non-magnetic

-

Outer Sheath: Black PVC (Polyvinyl-Chloride)

Material Advantages:

-

XLPE Insulation: Superior thermal endurance (90°C), high dielectric strength, and aging resistance

-

PVC Protection: Mechanical robustness, moisture resistance, and cost-effectiveness

-

AWA Armour: Lightweight corrosion resistance compared to steel, non-magnetic properties

Applications:

Ideal for fixed installations requiring durable power transmission:

• Power distribution networks (primary/secondary)

• Industrial plant wiring & machinery supply

• Renewable energy connections (solar/wind farms)

• Infrastructure projects (street lighting, tunnel electrification)

• Direct burial in ground without additional conduit

• Cable duct systems & outdoor risers

Technical Specifications (IEC 60502-1 0.6/1kV):

| Core Size (mm²) | Cond. Diam. (mm) | XLPE Thick. (mm) | PVC Bedding (mm) | AWA Wire (mm) | PVC Sheath (mm) | Overall Diam. (mm) | Copper Weight (kg/km) | Aluminium Armour Weight (kg/km) |

|---|---|---|---|---|---|---|---|---|

| 1x1.5 | 1.38 | 0.7 | 1.0 | 0.8 | 1.8 | 10.0 | 143.8 | 134.5 |

| 1x2.5 | 1.78 | 0.7 | 1.0 | 0.8 | 1.8 | 10.4 | 162.4 | 146.9 |

| 1x4 | 2.25 | 0.7 | 1.0 | 0.8 | 1.8 | 10.9 | 187.0 | 162.2 |

| 1x6 | 2.76 | 0.7 | 1.0 | 0.8 | 1.8 | 11.4 | 216.3 | 178.9 |

| 1x10 | 4.00 | 0.7 | 1.0 | 0.8 | 1.8 | 12.6 | 278.7 | 216.1 |

| 1x16 | 5.10 | 0.7 | 1.0 | 0.8 | 1.8 | 13.7 | 353.0 | 255.5 |

| 1x25 | 6.30 | 0.9 | 1.0 | 0.8 | 1.8 | 15.3 | 471.7 | 319.2 |

| 1x35 | 7.00 | 0.9 | 1.0 | 0.8 | 1.8 | 16.0 | 574.4 | 361.9 |

| 1x50 | 8.20 | 1.0 | 1.0 | 1.25 | 1.8 | 18.3 | 768.2 | 480.8 |

| 1x70 | 10.00 | 1.1 | 1.0 | 1.25 | 1.8 | 20.3 | 1014.0 | 592.2 |

| 1x95 | 11.60 | 1.1 | 1.0 | 1.25 | 1.8 | 21.9 | 1284.0 | 704.1 |

| 1x120 | 13.00 | 1.2 | 1.0 | 1.6 | 1.8 | 24.2 | 1601.8 | 870.7 |

| 1x150 | 14.60 | 1.4 | 1.0 | 1.6 | 1.8 | 26.2 | 1931.3 | 1019.0 |

| 1x185 | 16.20 | 1.6 | 1.0 | 1.6 | 1.8 | 28.2 | 2320.1 | 1182.8 |

| 1x240 | 18.40 | 1.7 | 1.0 | 1.6 | 1.9 | 30.8 | 2900.7 | 1426.0 |

| 1x300 | 20.60 | 1.8 | 1.0 | 1.6 | 1.9 | 33.2 | 3509.0 | 1665.6 |

| 1x400 | 23.80 | 2.0 | 1.2 | 2.0 | 2.1 | 38.4 | 4628.7 | 2216.6 |

| 1x500 | 26.60 | 2.2 | 1.2 | 2.0 | 2.2 | 41.8 | 5708.8 | 2646.8 |

| 1x630 | 30.00 | 2.4 | 1.2 | 2.0 | 2.3 | 45.8 | 7125.0 | 3206.9 |

| 1x800 | 34.00 | 2.6 | 1.4 | 2.5 | 2.5 | 52.0 | 9119.4 | 4132.8 |

(Conductor: Copper | Insulation: XLPE | Armour: Aluminium Wire | Sheath: PVC)

Standards & Certifications:

-

Compliance: IEC 60502-1:2004

-

Voltage Rating: 0.6/1 kV (U₀/U)

-

Operating Temp: -15°C to +90°C (Conductor max: 90°C under load)

-

Quality Systems: ISO 9001 Certified Manufacturing

-

Regulatory: CE Marked

Engineering Selection Notes:

• AWA advantage: Lighter than SWA with inherent corrosion resistance

• Current Capacity: XLPE insulation permits ≈20% higher ampacity than equivalent PVC-insulated cables

• EMC Consideration: Non-magnetic armour reduces electromagnetic interference

• Weight Data: Critical for support spacing design and installation planning