High Voltage Silicone Rubber Insulated Cable

High Voltage Silicone Rubber Insulated Cable

3-50kV High-Temp Silicone Rubber HV Cable - Tinned Copper Conductor (-60°C to 200°C Rated)

Product Overview

Engineered for extreme environments, this high-voltage silicone rubber insulated cable delivers exceptional performance in applications demanding both elevated voltage handling (up to 50kV) and wide temperature tolerance (-60°C to +200°C). Featuring tinned copper conductors and premium silicone insulation, it's ideal for high-temperature electrical systems in industrial, appliance, and specialized equipment applications.

Construction & Materials

| Layer | Material & Specification | Key Properties |

|---|---|---|

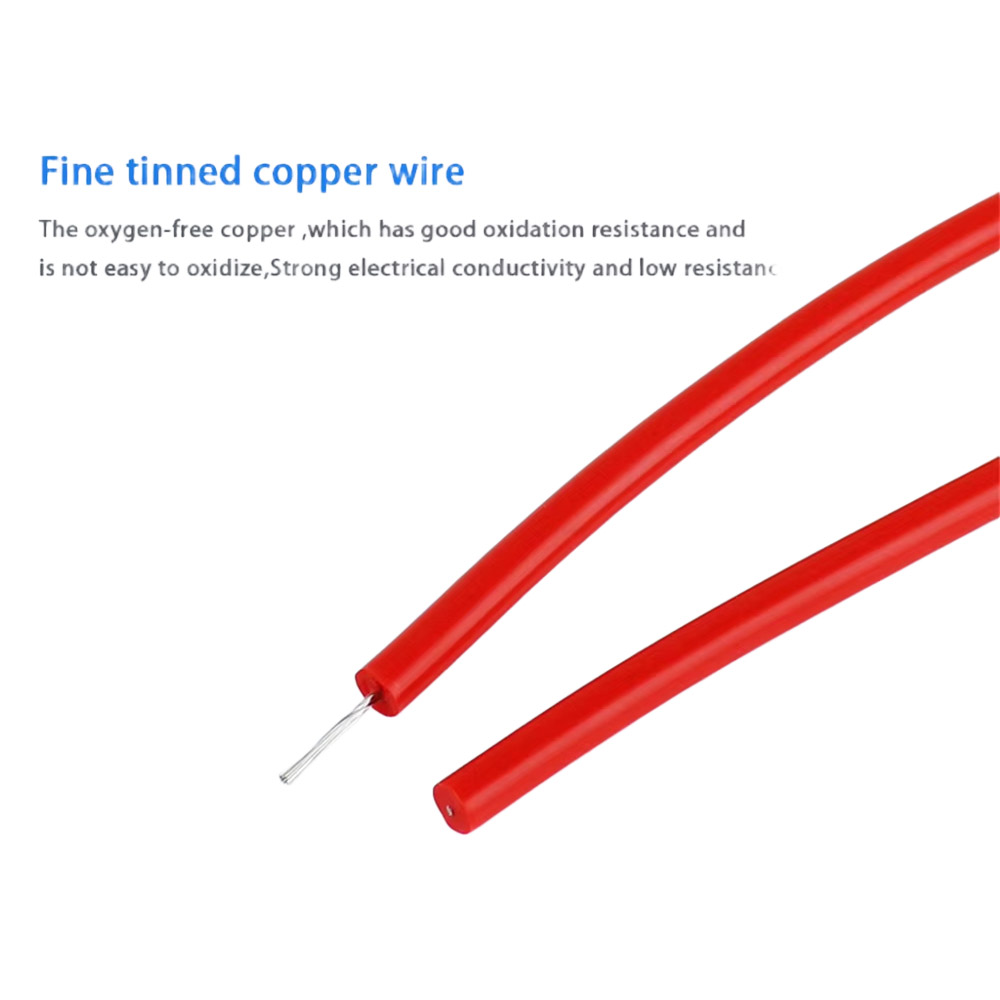

| Conductor | Tinned Copper | Superior corrosion resistance, solderability |

| Insulation | High-Grade Silicone Rubber | Extreme temp stability, excellent dielectric strength |

Key Technical Specifications

| Parameter | Specification | Tolerance |

|---|---|---|

| Rated Voltage | 3kV, 6kV, 10kV, 15kV, 20kV, 25kV, 30kV, 40kV, 50kV | - |

| Temp. Range | -60°C to +150°C (Standard) / +200°C (Optional) | - |

| Conductor Finish | Electrotinned Copper | - |

| OD Tolerance | - | ±0.10 mm |

| Insulation Material | Silicone Rubber | - |

Standard Sizes & Construction

| AWG | Cross-Section (mm²) | Conductor Structure | Overall Diameter (mm) | Standard Length (m) |

|---|---|---|---|---|

| 26 | 0.15 | 7/0.16 | 5.6 | 100 |

| 24 | 0.20 | 7/0.20 | 5.8 | 100 |

| 22 | 0.30 | 19/0.15 | 6.0 | 100 |

| 20 | 0.50 | 19/0.18 | 6.1 | 100 |

| 18 | 0.75 | 19/0.23 | 6.4 | 100 |

| 16 | 1.25 | 19/0.30 | 6.8 | 100 |

| 14 | 2.00 | 19/0.37 | 7.1 | 100 |

(Note: Custom lengths/voltages available upon request)

Primary Applications

Designed for challenging electrical environments:

-

High-Temperature Equipment: Ovens, industrial heaters, thermal processing systems

-

Electrical Appliances: Internal wiring for household/industrial appliances

-

Electrothermal Systems: Heating elements, industrial furnaces

-

Industrial Machinery: Motor leads, control circuits in high-heat zones

-

Specialized Electronics: High-voltage test equipment, power supply connections

-

Computer Systems: Internal HV wiring in servers/specialized computing hardware

Engineering Selection Guide

-

Voltage Selection: Choose voltage rating ≥1.5× operating voltage for safety margin

-

Temperature Rating:

-

Standard: Continuous operation at 150°C

-

High-Temp: For sustained 200°C environments

-

-

Conductor Sizing:

-

AWG 26-22: Signal/low-current circuits

-

AWG 20-14: Power connections (verify ampacity for load)

-

-

Environmental Considerations:

-

Ideal for dry/high-heat environments

-

Avoid prolonged UV exposure without protection

-

Not recommended for direct burial or wet locations

-

-

Bend Radius: Minimum 4× overall diameter for repeated flexing

Material Advantages

| Component | Key Benefits |

|---|---|

| Tinned Copper | Enhanced oxidation resistance, improved solderability |

| Silicone Insulation | • Maintains flexibility at -60°C • Withstands 200°C continuous • High dielectric strength • Flame retardant properties |

Compliance & Standards

Note: Specific standards not provided in source - typical compliance includes:

-

UL 3239 (Silicone Insulated Wire)

-

RoHS/REACH compliant

-

Custom certification available upon request